ORBAL oxidation ditch type similar dephosphorization denitrogenation integrated A2O technique

An oxidation ditch and denitrification technology, which is applied in the field of sewage treatment, can solve the problems of short residence time, long residence time, and large equipment footprint, and achieve low equipment investment costs, saving floor space, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

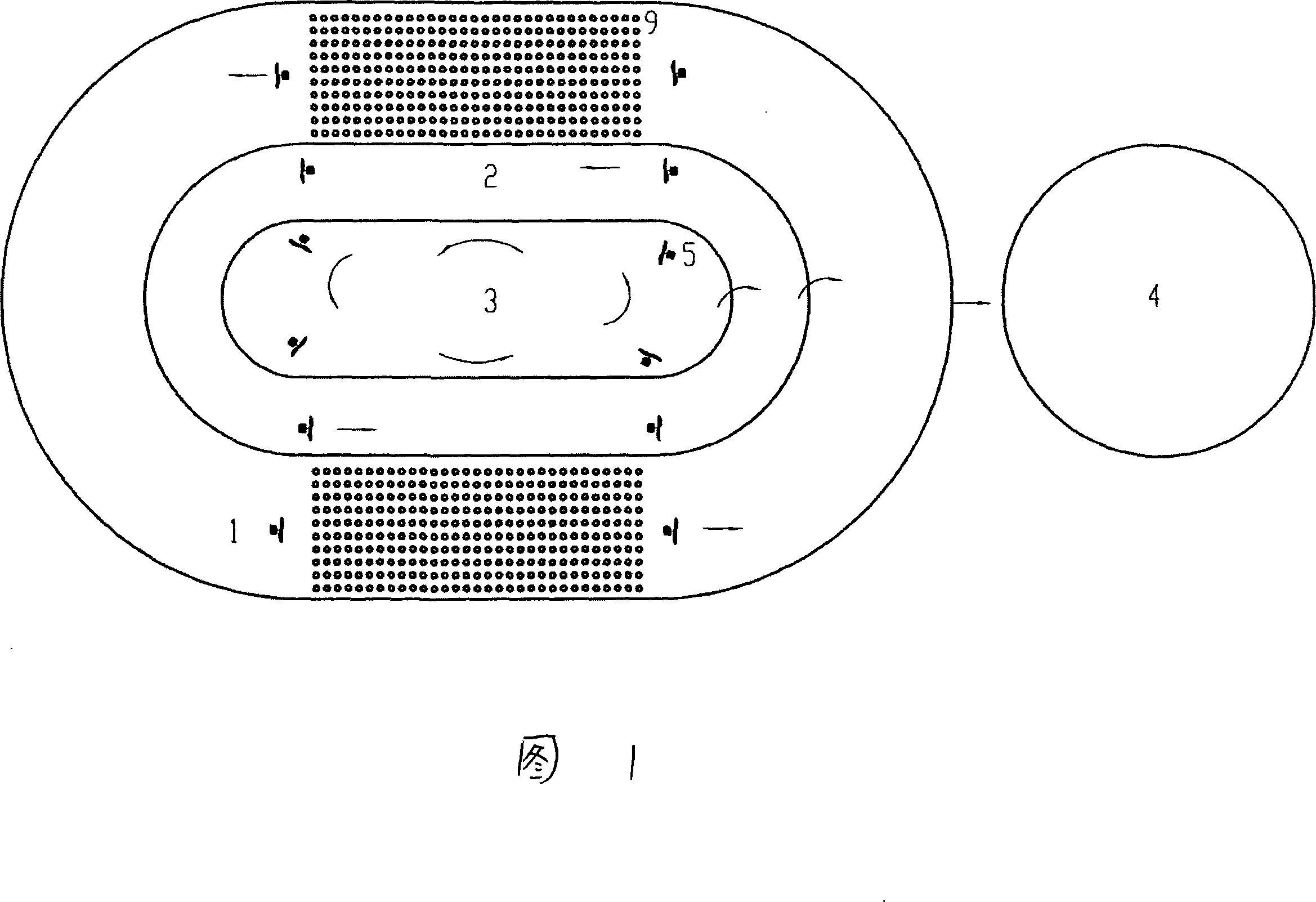

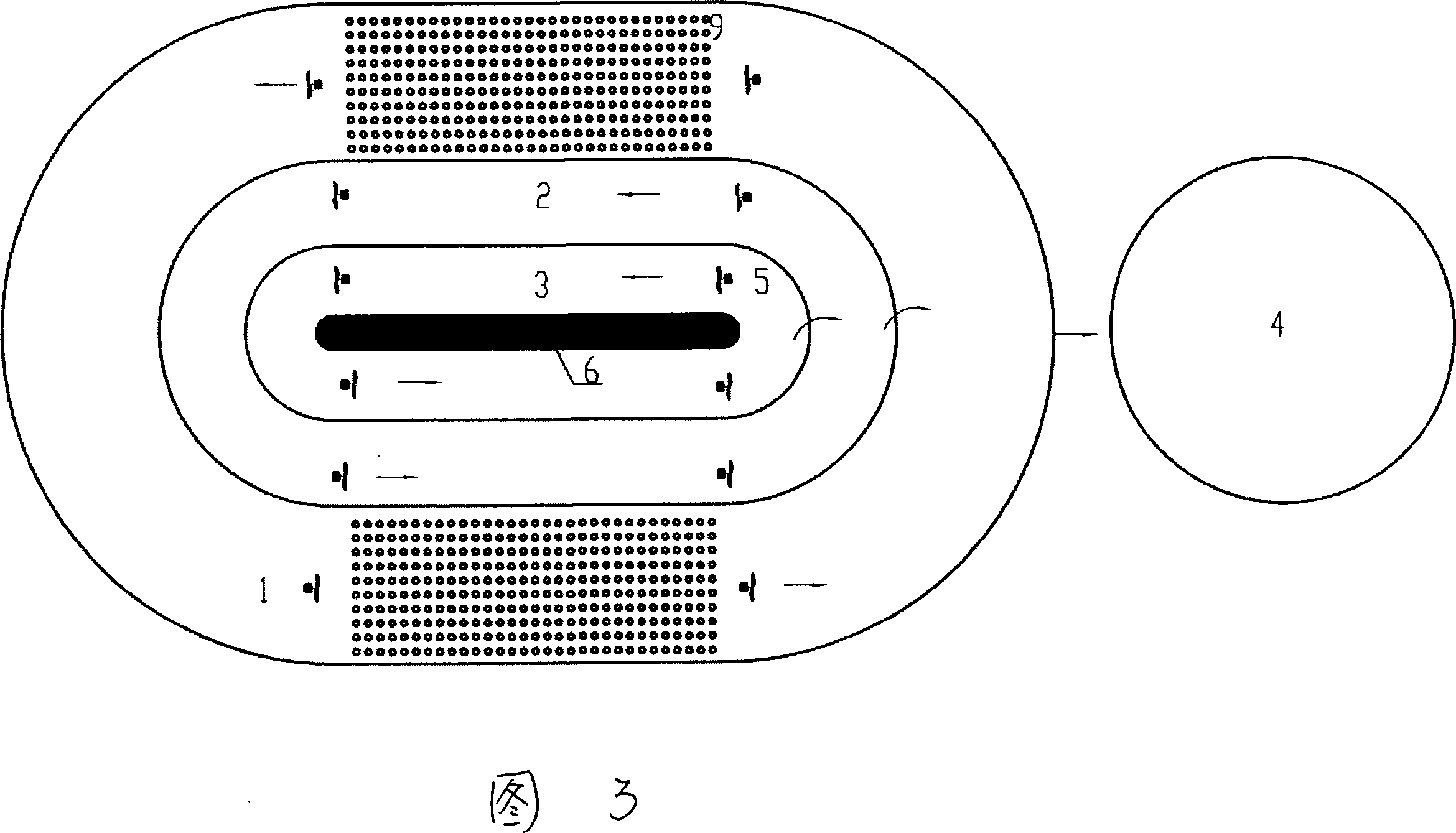

[0024] Example 1, ORBAL-like oxidation ditch integrated phosphorus and nitrogen removal A 2 O process, the sewage flows through the ORBAL oxidation ditch-like inner pool, middle ditch and outer ditch in turn, the inner pool is designed as anaerobic pool 3, the middle ditch is designed as anoxic pool 2, the outer ditch is designed as aerobic pool 1, and the aerobic A microporous aerator 9 is arranged in the pool 1, and the residence time in the anaerobic pool 3, the anoxic pool 2, and the aerobic pool 1 are respectively controlled to be 1-2 hours, 0.5-3 hours, and more than 7 hours. The underwater propeller 5 is used as push flow, and the sewage from the aerobic tank enters the secondary sedimentation tank 4 arranged outside the ORBAL oxidation ditch for biochemical treatment.

Embodiment 2

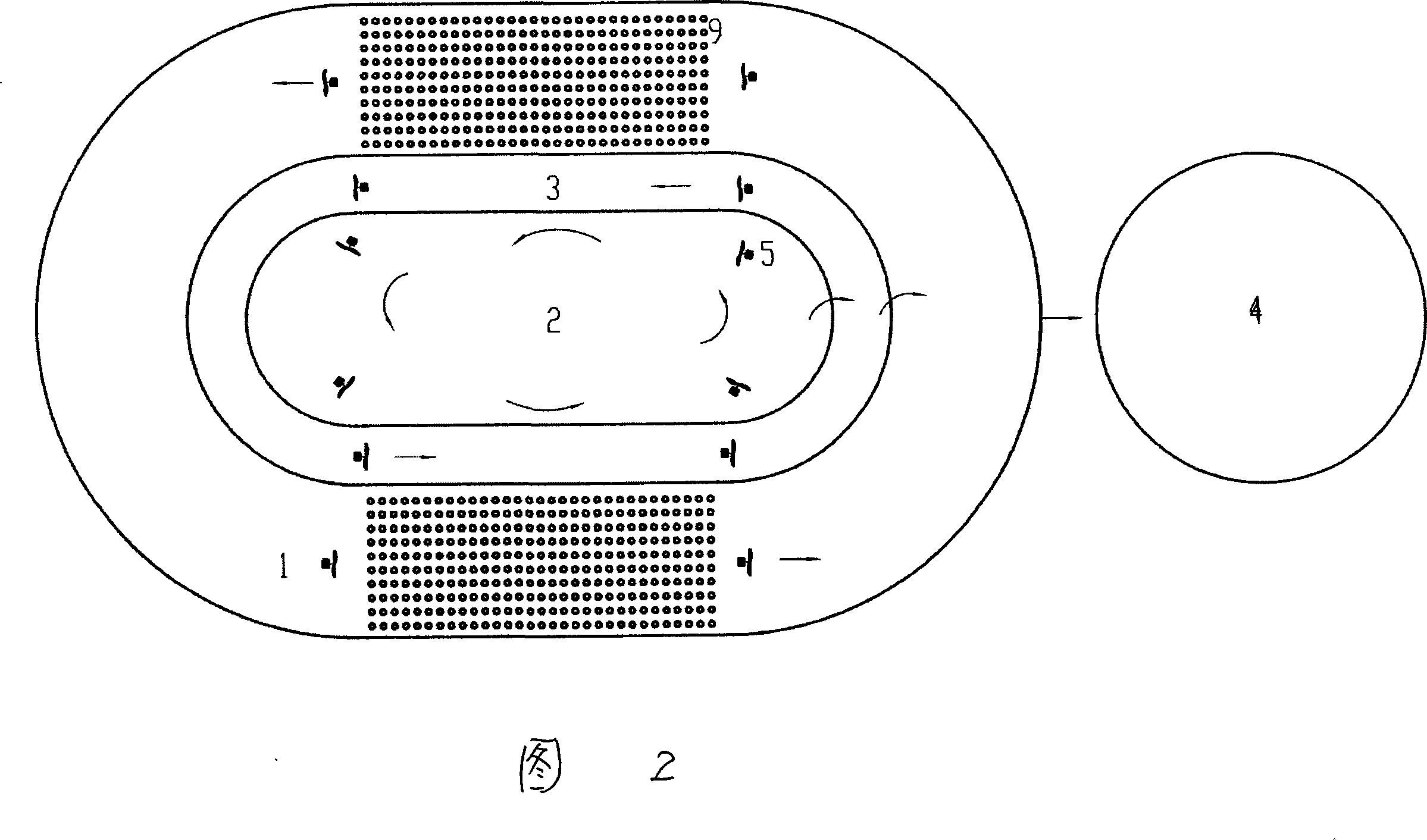

[0025] Embodiment 2, referring to Example 1, the inner tank is designed as anoxic tank 2, the middle ditch is designed as anaerobic tank 3, and the sewage is treated in the anoxic tank 2, anaerobic tank 3, aerobic tank 1, and secondary sedimentation tank 4. .

Embodiment 3

[0026] Example 3, with reference to Example 1, a central island partition wall 6 is placed in the middle of the inner ditch anaerobic pool 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com