Functional rubber strengthening agent and preparation method thereof

A rubber reinforcing agent and functional technology, which is applied in the field of functional additives and its preparation, can solve the problems of uncontrollable conditions and low grafting rate, and achieve the effects of low hysteresis loss, high grafting rate and simple process

Inactive Publication Date: 2008-05-28

SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Considering the structure of starch and rubber, most of them use acids or acid anhydrides containing c=c double bonds to graft and modify starch, but the starch esters prepared by this method often have a very low grafting rate and the conditions are difficult to control

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Dihydropyran (liquid state) 20ml / protonic acid 0.05g / stirring at 95°C for 0.5 hours / reaction for 1 hour / component B:starch (mass ratio)=1:100.

Embodiment 2

[0027] Application examples

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

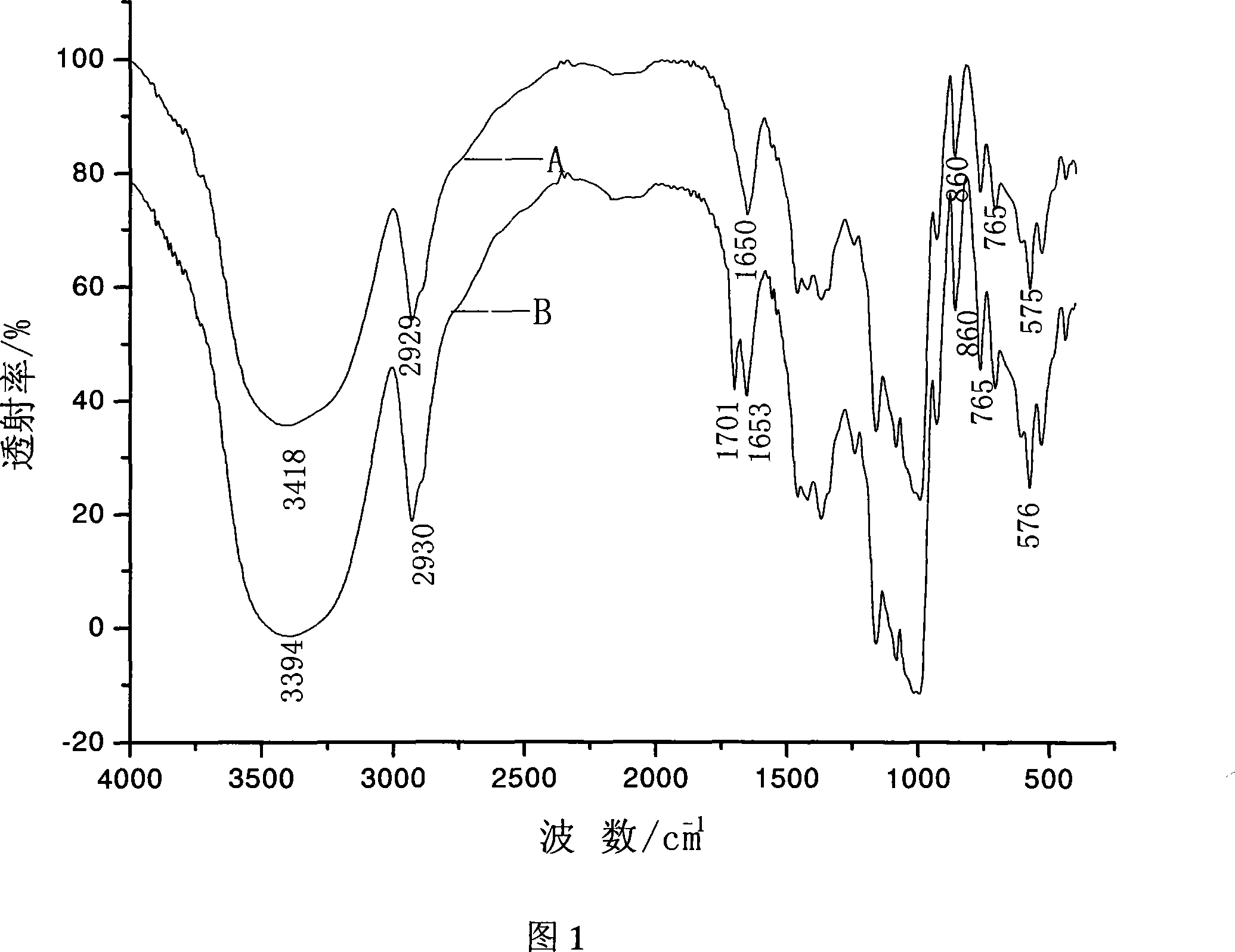

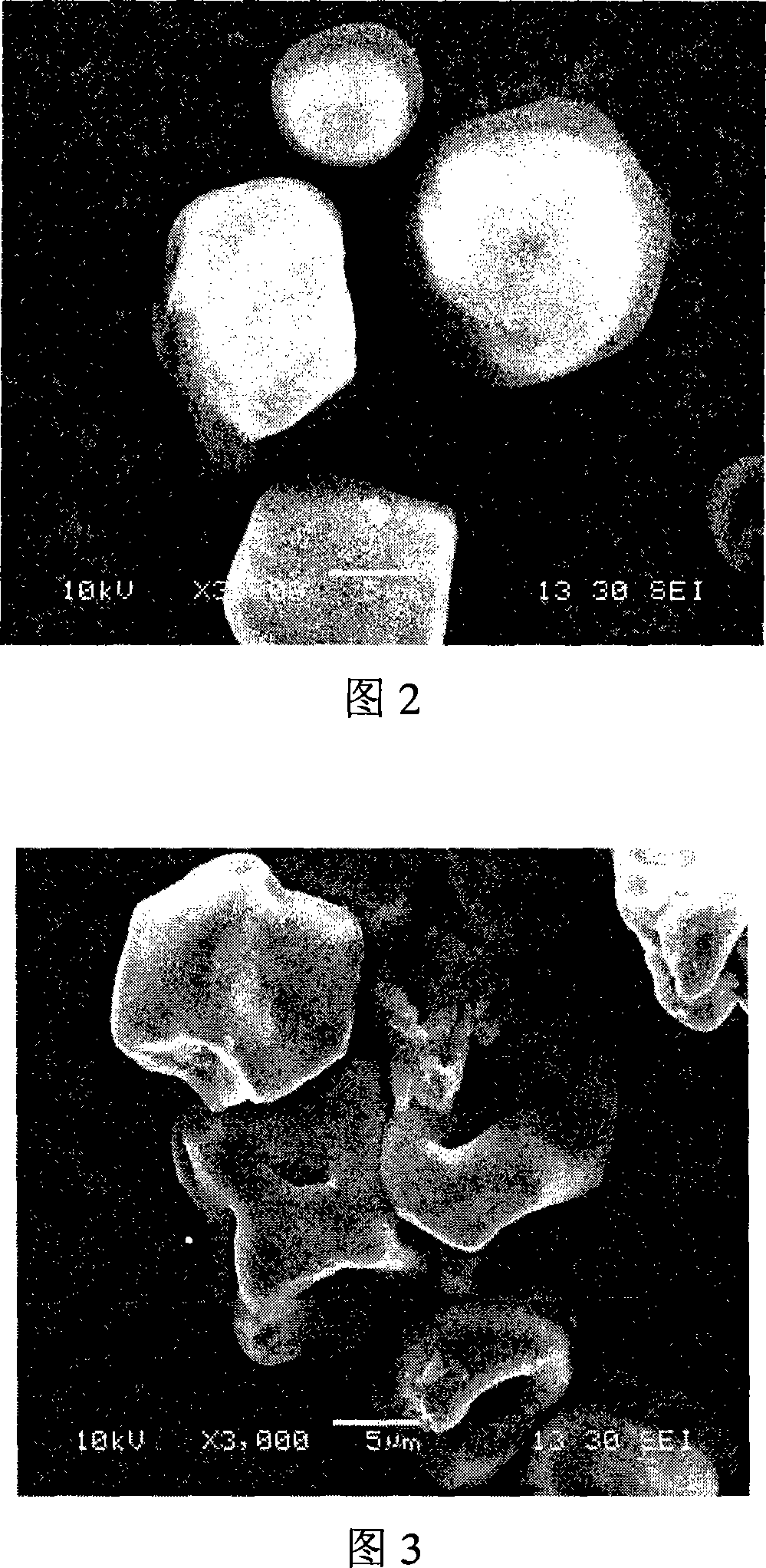

Provided is a functionality rubber strengthening agent and process for preparation, which relates to a chemical industry auxiliary agent and a process for preparation. The method of preparation is as follows: a, under the condition of mechanical agitation, starch and initiating agent are charged in N, N-dimethylformamide solution whose temperature is 70-100 DEG C to gelatinize for 0.5-2 hours, b, under the condition of mechanical agitation, hydroxyl protecting agent component A and protonic acid component B is charged in the reactive solution of the first step, and reacts for 0.5-2 hours under the temperature of 70-100 DEG C to confect starch derivative through scouring, suction, drying and comminuting, and then coupling agent is charged in the liquor to confect the functionality rubber strengthening agent. The strengthening agent is simple in manufacturing technique, low in the cost and comparatively high in environment-friendly extent, which is widely applied in various types of tires and other rubber products.

Description

technical field [0001] The invention relates to a chemical auxiliary agent and a preparation method thereof, in particular to a functional auxiliary agent used for rubber reinforcement, improving the elasticity of vulcanized rubber, reducing heat generation and hysteresis loss, and a preparation method thereof. Background technique [0002] Modified starch is a substance called "engineered biopolymer filler", which is obtained from ordinary starch through various modifications. In recent years, research on starch denaturation at home and abroad has progressed rapidly, and its products are widely used in textiles, food, medicine, petrochemicals, papermaking and other fields. However, starch is rarely used in rubber. Using starch as a reinforcing agent for rubber can obtain new rubber composite materials with low heat generation, high elasticity, and low hysteresis. [0003] Due to the limitations of the structure of starch itself, the reinforcing effect of pure starch as a r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L3/08C08K5/54C08K5/10C08L21/00

Inventor 方庆红梁悦

Owner SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com