Antibacterial fine diner silicon-containing polyester staple fiber and method for making same

A polyester staple fiber and antibacterial technology, which is applied in the field of antibacterial fine denier silicon polyester staple fiber and its preparation, can solve the problems of antibacterial agent shedding, broken ends, and hairy filaments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw materials: 98 kg of polyester chips, 2 kg of nano-layered silver-based inorganic antibacterial agent.

[0023] Polyester chips are dried and pre-crystallized (drying temperature 170°C, drying time 3h, drying medium is hot air with a dew point of -70°C), blended with nano-layered silver-based inorganic antibacterial agents, and then melt-spun (spinning process parameters See Table 1), the first tanker oiling, clustering, two drafting, crimping (control the number of crimps is about 10%, and the curling rate is about 7%), the second spraying oiling (tanker oiling accounts for 80% %, spraying and oiling accounted for 20%, and the total oiling rate was 0.3%), cutting, relaxing heat setting, and packing.

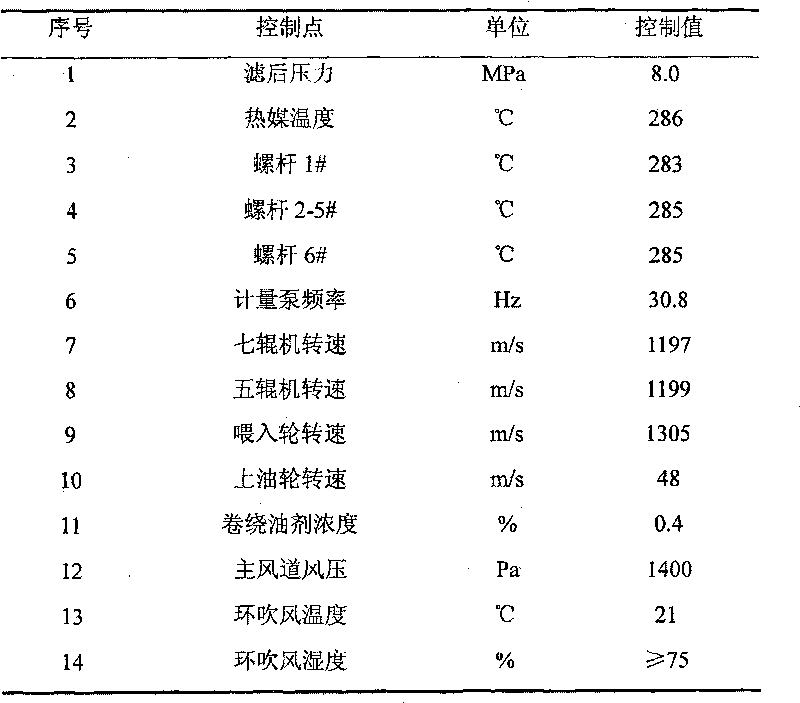

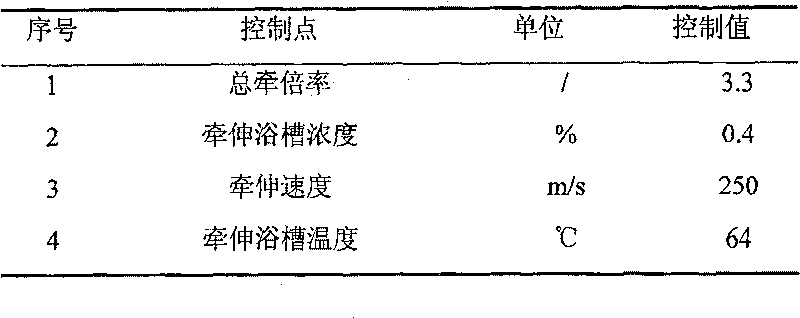

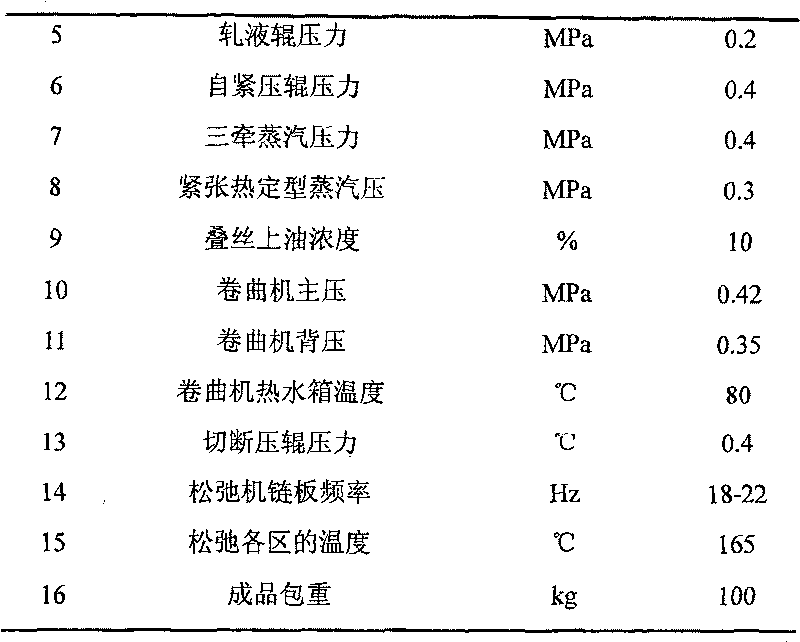

[0024] The melt-spinning process flow adopted, and some of the spinning process parameters are shown in Table 1.

[0025] Table 1 The process parameters before spinning

[0026]

[0027] Combined oiling method is adopted to control the oiling rate.

[0028] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com