Micro-lubrication equipment and method

A technology of lubricating equipment and lubricants, which is used in the direction of mechanical equipment, lubricating parts, engine lubrication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

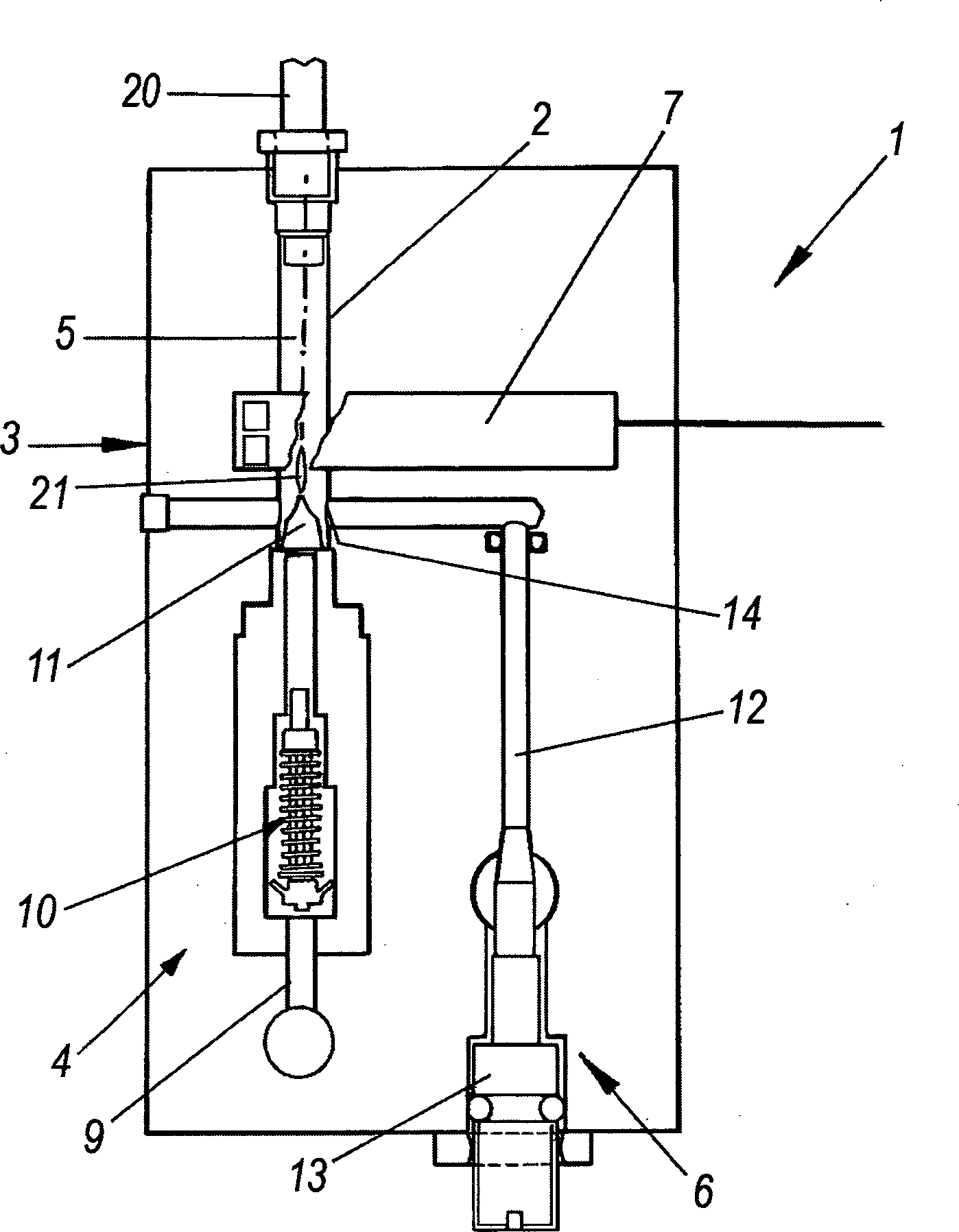

[0023] Referring to these figures, these figures show the use of two-phase mixture for the minimal lubrication equipment, the two-phase mixture through the mixing line 2 along the two-phase mixer 3 to distribute the first liquid lubricant phase 21 for the first The liquid lubricant phase is obtained in the flow of the second transport phase.

[0024] The mixing duct 2 is preferably made of a transparent material.

[0025] The first lubricant phase 21 is in particular oil and the second transport phase for the first phase is in particular air.

[0026] The use of the device 1 is in particular the micro-lubrication of ball bearings or the machining of chip removal tools.

[0027] The two-phase mixer 3 comprises: a first distribution unit 4 for metering the first phase distributed directionally along the axis 5 of the mixing duct 2; and a second supply unit 6 for feeding a flow of the second phase to the mixing in pipeline 2.

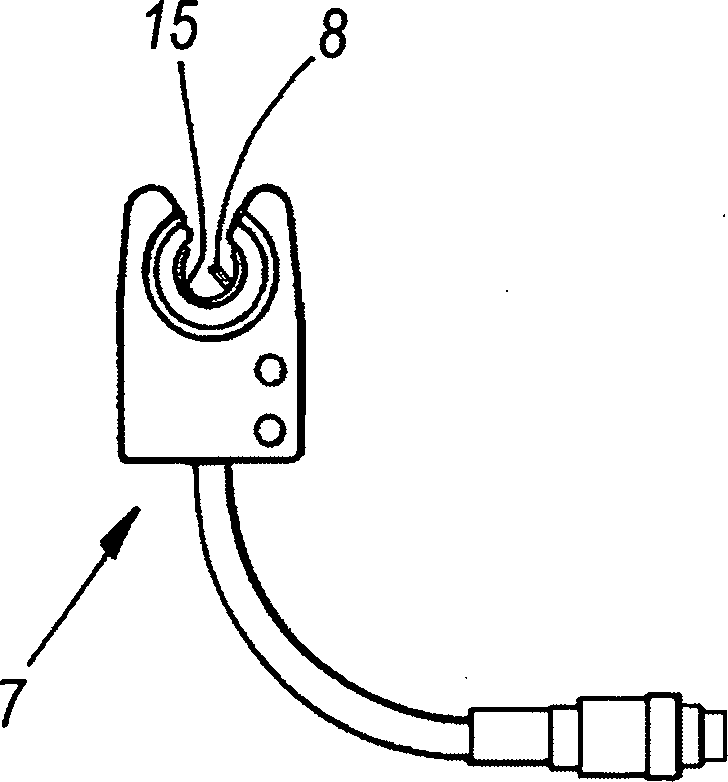

[0028] The sensor 7 for generating a signal indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com