Substrate

A substrate and dielectric film technology, which is applied in the plating of superimposed layers, vacuum evaporation plating, coating, etc., can solve the problem of inability to deposit silicon dioxide layers, and achieve the effect of low thermal budget

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

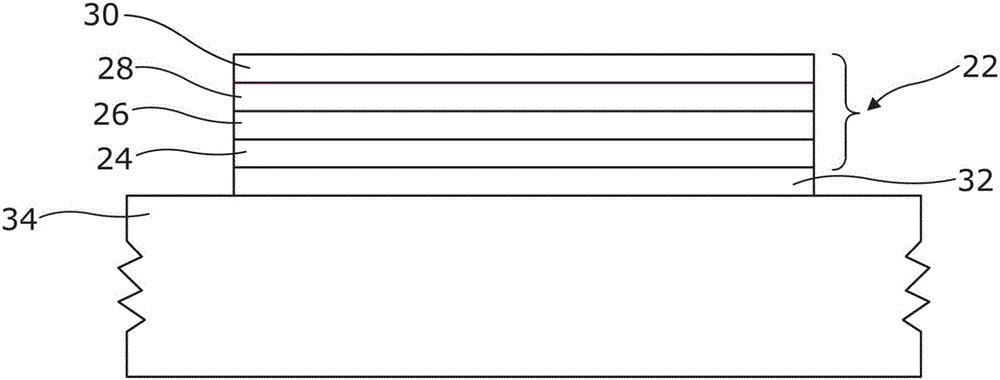

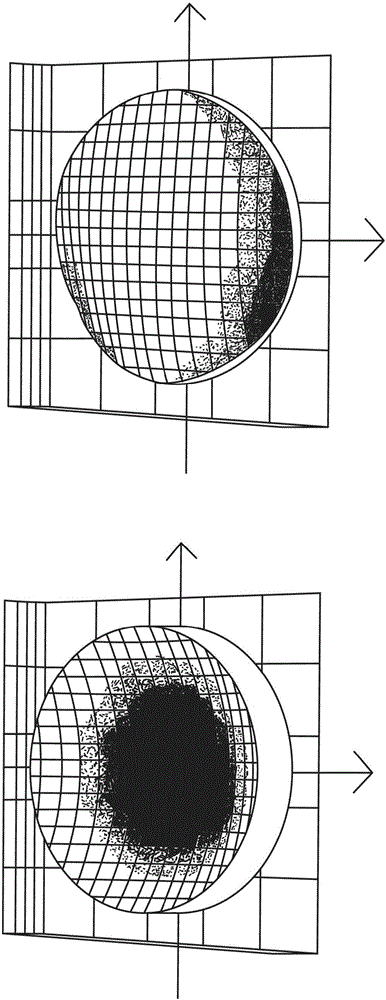

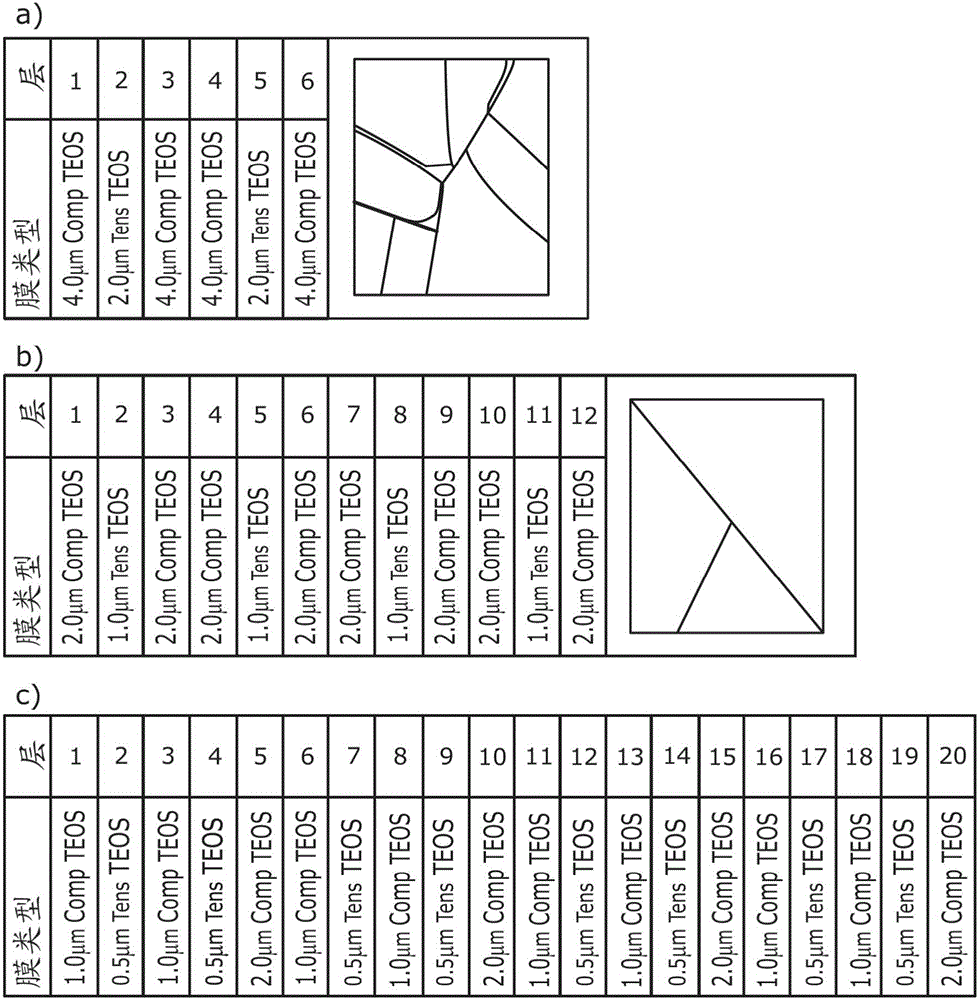

[0047] The present invention provides a dielectric film composed of a plurality of layers. In the film, at least some adjacent layers are subjected to alternating stresses, ie compressive and tensile stresses. By judicious selection of the process parameters used in depositing the dielectric film, any addition of stress to the substrate or structure on which the dielectric film is deposited can be avoided. Alternatively, it is also possible to vary the overall stress experienced by the substrate or structure together with the dielectric film. Typically, the above is done to reduce overall stress.

[0048] The invention is applicable to a wide range of dielectric films that can be deposited on a wide range of substrates. The substrate on which the dielectric film can be deposited may form part of a larger structure. Again, the invention can be used in a wide variety of configurations. An advantage of the present invention is that relatively thick dielectric films can be dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com