Concrete pedestal pile construction equipment and its construction method

A technology of construction equipment and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as broken piles, large side wall friction, necking, etc., to achieve improved work efficiency, reduced soil squeezing effect, and reduced The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

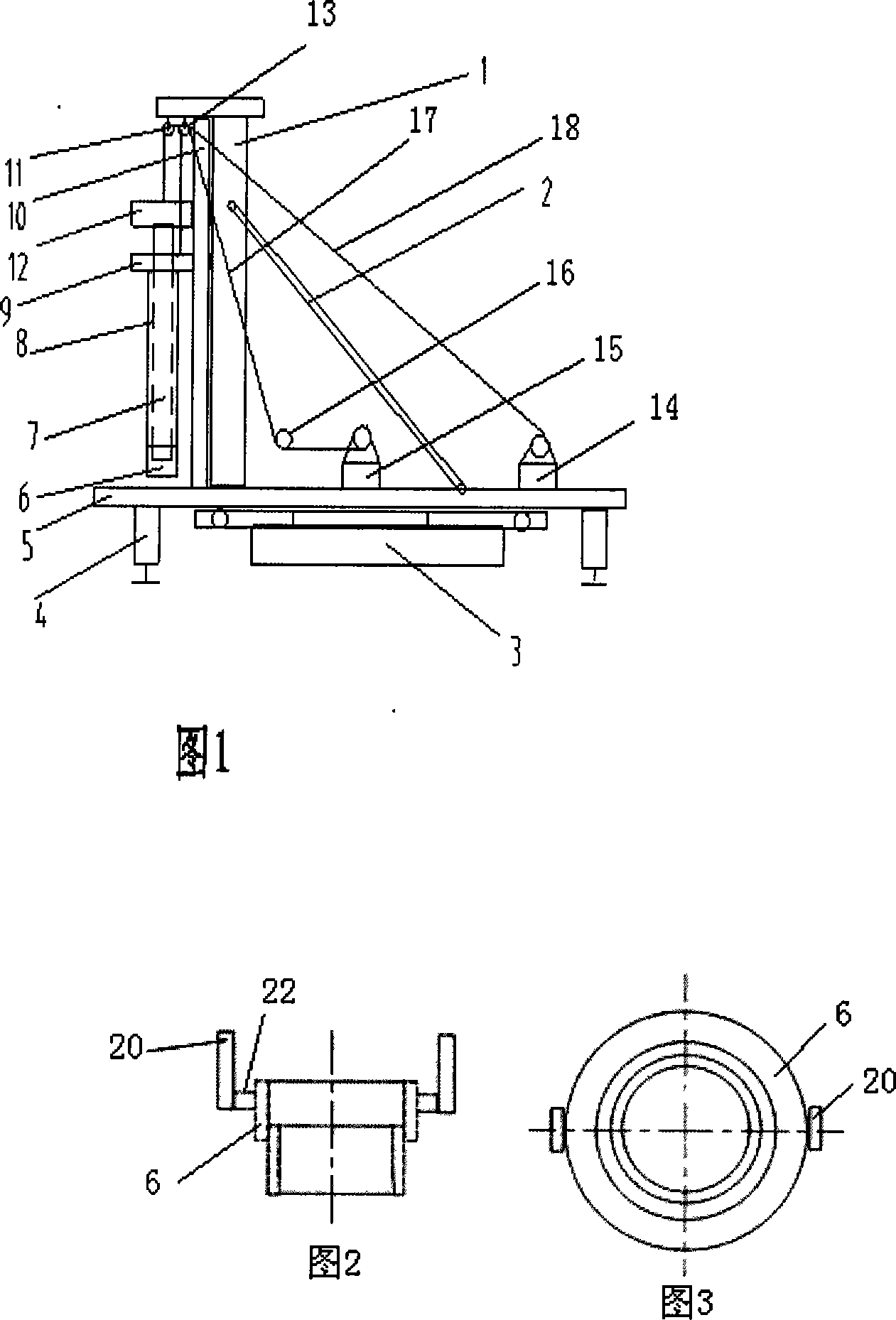

[0046] As shown in Figure 1, a construction equipment for concrete bottom expansion piles includes a chassis girder 5 with four telescopic hydraulic outriggers 4 and a running mechanism 3 at the bottom, and the front end of the chassis girder 5 is fixedly connected with a vertical guide rail The main frame 1 of 10, the main frame 1 is supported and connected to the chassis girder 5 by two diagonal braces 2, and the other ends of the diagonal braces 2 are respectively connected to different positions on the chassis girder, and the two diagonal braces 2 are connected to the main frame The connection with the chassis girder forms a three-point support structure. The beam of the main frame 1 is provided with a pulley block, and the chassis girder 5 is fixedly connected with a main hoist and an auxiliary hoist. The steel rope 2 17 protruding from the auxiliary hoist 15 bypasses the auxiliary After the pulley 16 goes around the auxiliary pulley 13 of the pulley block, it is connected...

Embodiment 2

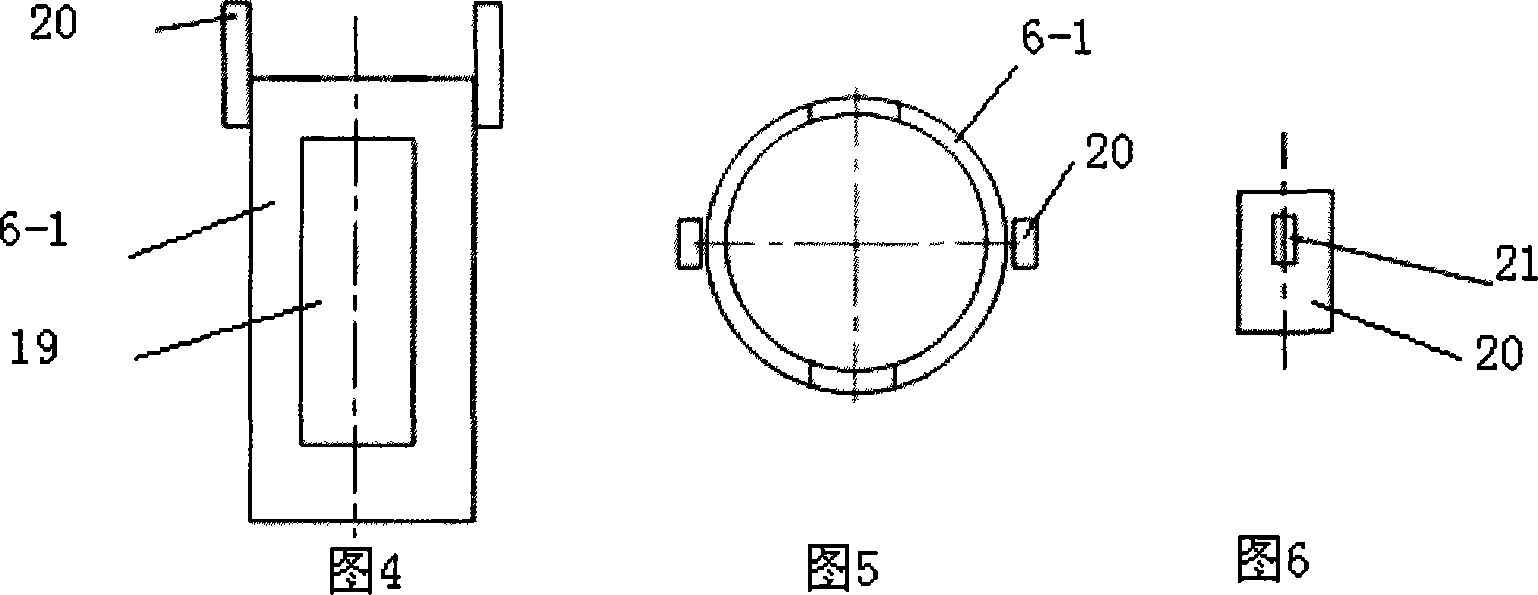

[0060] As shown in Fig. 1 and Fig. 4 to Fig. 6, a kind of construction equipment of concrete bottom expansion pile, earth taker adopts lateral through-hole type earth taker 6-1, and the lower end of casing 8 is equipped with take-off lug 20 The earthenware 6-1 connects the earthenware 6-1 with the casing 8 through the elongated hole 21 on the lifting lug 20 and the corresponding connection hole on the casing 8 with screws, and the earthenware is provided with a digging on the pipe wall. The tubular structure of soil hole 19, other structures are with embodiment 1. For relatively loose soil layer, should use the lateral through-hole type soil fetcher of this embodiment.

[0061] Utilize the construction method of the concrete expanded bottom pile of the construction equipment of above-mentioned concrete expanded bottom pile, comprise the steps:

[0062] a) Stand the casing with a special earth picker at the bottom on the foundation surface of the specified pile position in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com