Self-advancing type double pump clogging-free dredging machine

A self-propelled, non-clogging technology, applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as high labor intensity, short row distance, and high power consumption. Achieve the effects of increased output, low lift and short row distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

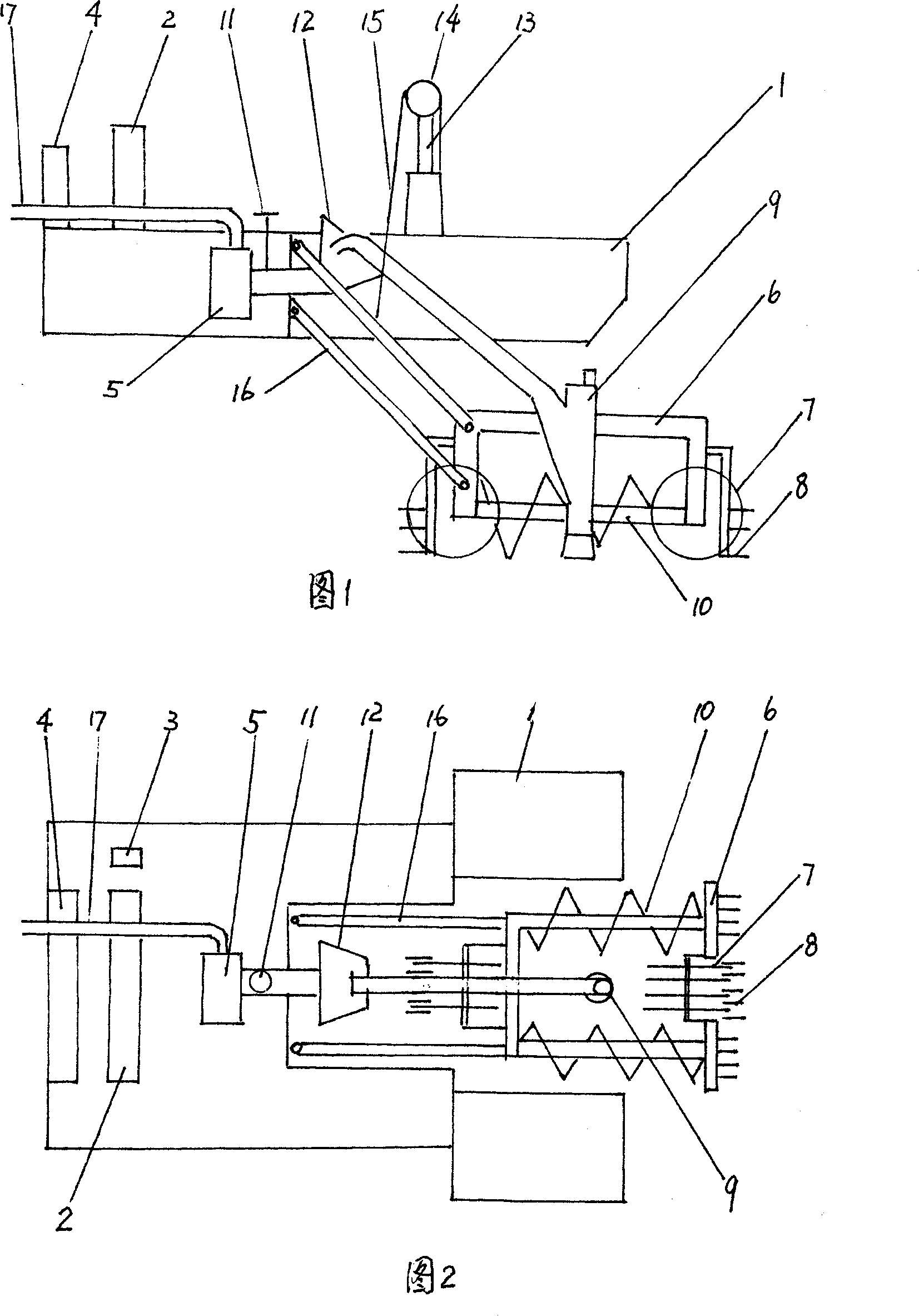

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail as:

[0014] In Figures 1 and 2, the floating body 1 floats on the water surface, the diesel engine 2, the oil pump 3, the oil tank 4, the mud pump 5, the lifting operation device and the machine head are all fixed on the floating body 1, and the diesel engine 2 communicates with the oil pump 3 and the mud through the transmission parts. The pump 5 is connected, and the oil pump 3 is respectively connected with the lifting operation device and the machine head through oil pipes. The machine head includes a frame 6, a disc hob 7, rake teeth 8, an axial flow pump 9 and a spiral drum 10. The front and rear of the frame 6 are parallel Four disc hobs 7 are installed, and the central shaft of the disc hob 7 is horizontally fixed on the frame 6. The central shaft and the axis of the spiral drum 10 are on the same plane, and the peripheral section of the disc hob 7 is S-shaped, drive sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com