Taper tube and ash returning pump and ash recombustion type circulated fluid bed combustion equipment

A technology of tapering and expanding and tapering pipes is applied in the field of fly ash reburning circulating fluidized bed combustion equipment, which can solve the problems of poor injection effect, large maintenance amount, ash leakage, etc., and achieve good injection effect and cost. Low and high stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

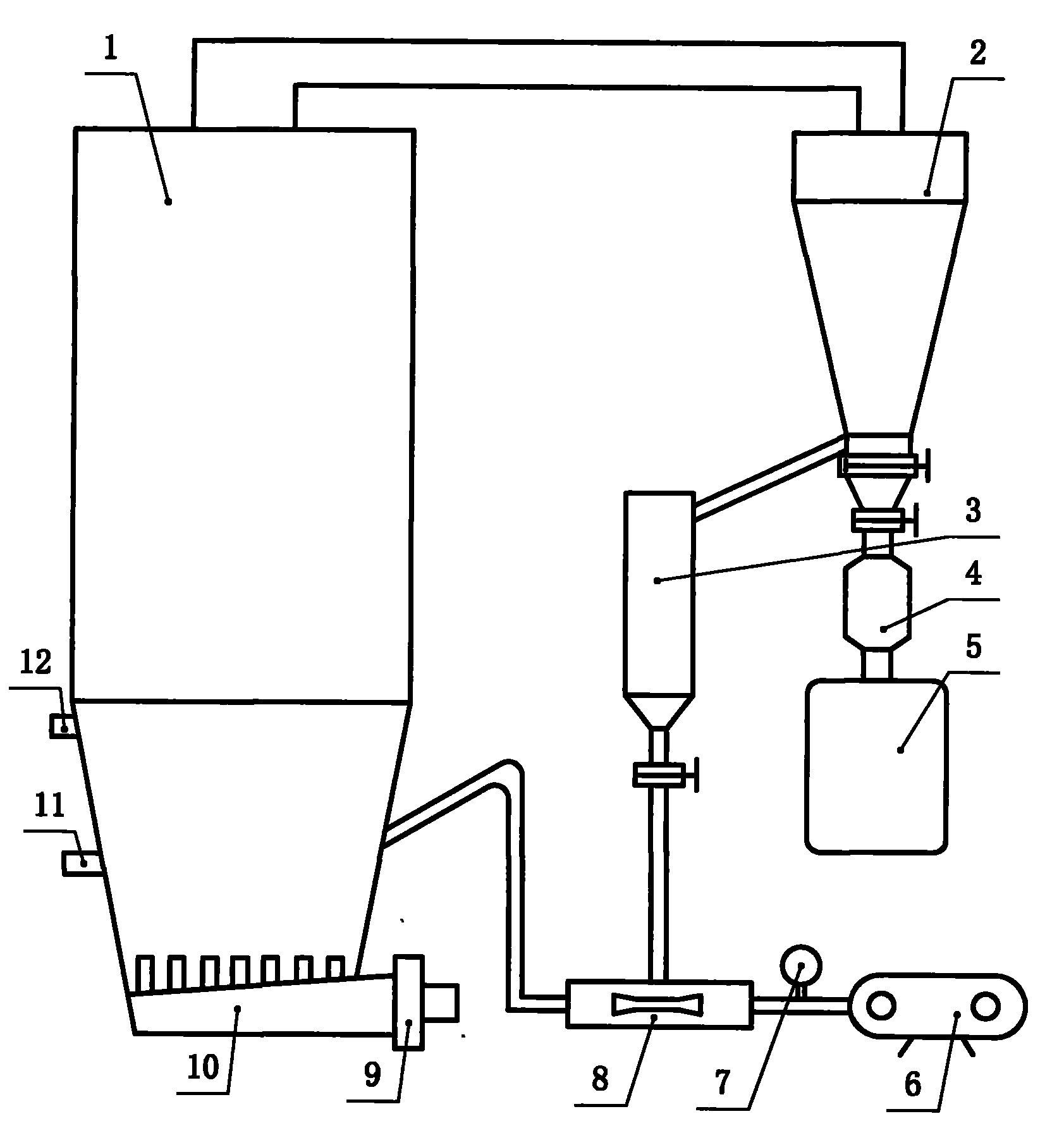

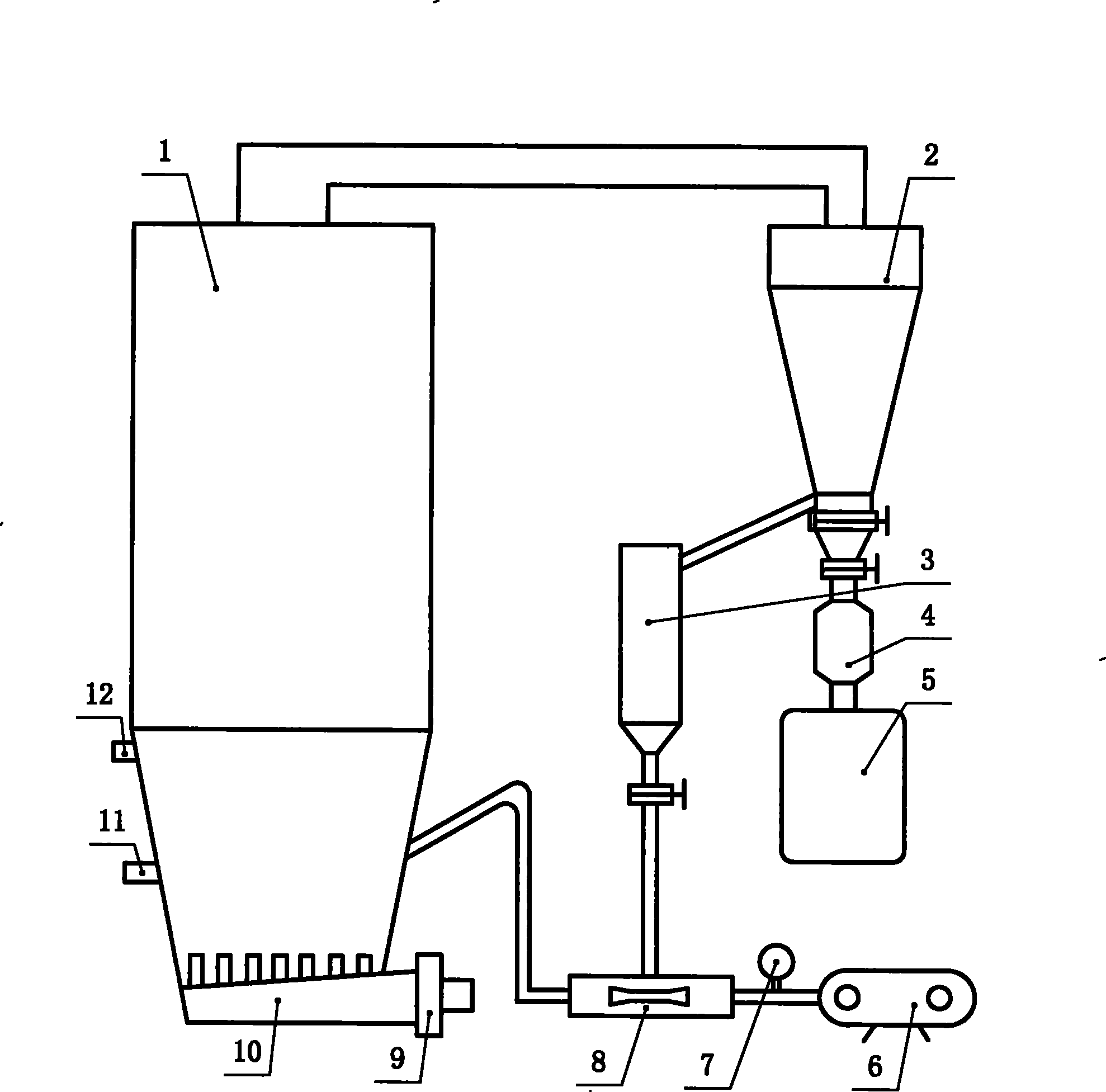

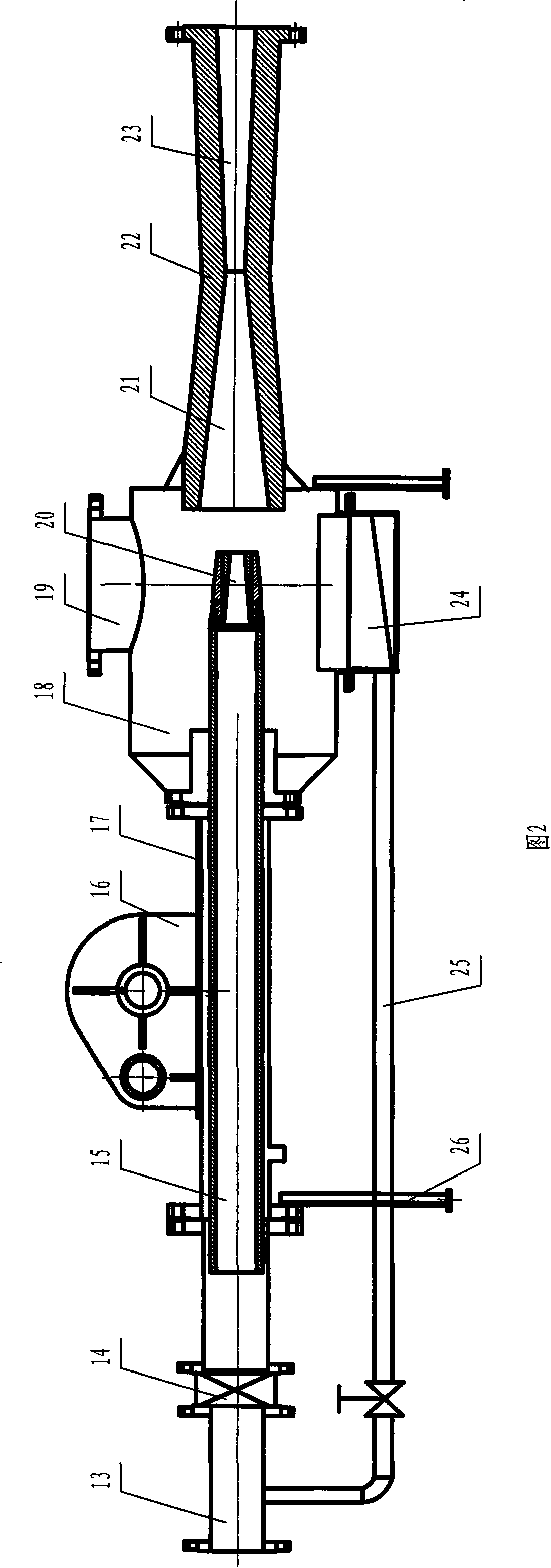

[0024] Embodiment one: referring to Fig. 1 and Fig. 2, among the figure, the burner 1 of fly ash reburning type circulating fluidized bed combustion equipment is provided with refueling device (not shown in the figure, is prior art), ignition device 9, The primary air chamber 10, the secondary air inlet 11 and the tertiary air inlet 12. The burner 1 is a circulating fluidized bed boiler. The ash inlet 19 provided at the upper end of the mixing chamber 18 of the ash pump 8 is connected, the Roots blower 6 is connected with the ventilation pipe 13 of the ash return pump 8, and the tapered and expanded pipe 22 of the ash return pump 8 is passed through the tapered pipe section at the discharge end. The fly ash pipe communicates with the dense phase area of the burner 1 . The pipe section connecting the fly ash pipe to the burner 1 is inclined downward, and its horizontal angle is 20°~50° (30° in the figure, of course, it can also be 25°, 35°, 40° or 45° as required) .

[0025...

Embodiment 2

[0032] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the reducer pipe section 21 and the expander pipe section 23 are split combined structures, and the reducer pipe section 21 and the expander pipe section 23 are respectively processed by turning and / or grinding of the pipe body, and the contacting ends of the two are fitted together and fixed by welding or fixed by flange connection or by bolts, which is convenient for processing and low in cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com