Tobacco and tobacco product arsenic content determination method

A technology for tobacco products and determination methods, applied in the field of physical and chemical testing, can solve the problems of many types and dosages of digestion reagents, complex pretreatment, expensive instruments, etc., achieve good technology promotion value, shorten analysis time, and reduce types and dosages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 working curve and determination of detection limit

[0021] 1. Main instruments and reagents

[0022] AAS800 atomic absorption spectrophotometer (PERKIN-ELMER company in the United States), equipped with THGA graphite tube and arsenic electrodeless discharge lamp; MWS-3+ microwave digestion system (BERGHOF company in Germany); H110 electronic balance (sensitivity 0.0001g, Germany SARTORIUS company).

[0023] 1000 μg / mL arsenic standard solution (provided by National Iron and Steel Research Institute); ammonium chlororhodium (analytical pure, Shanghai Jiushan Chemical Reagent Company); citric acid (analytical pure, Guangzhou Chemical Reagent Factory); 68% (mass fraction) nitric acid ( Superior grade, Guangzhou Donghong Chemical Factory); 30% (mass fraction) hydrogen peroxide (superior grade, Guangdong Guanghua Reagent Factory); ultrapure water (prepared by Milli-Q); tobacco leaves and cigarette samples.

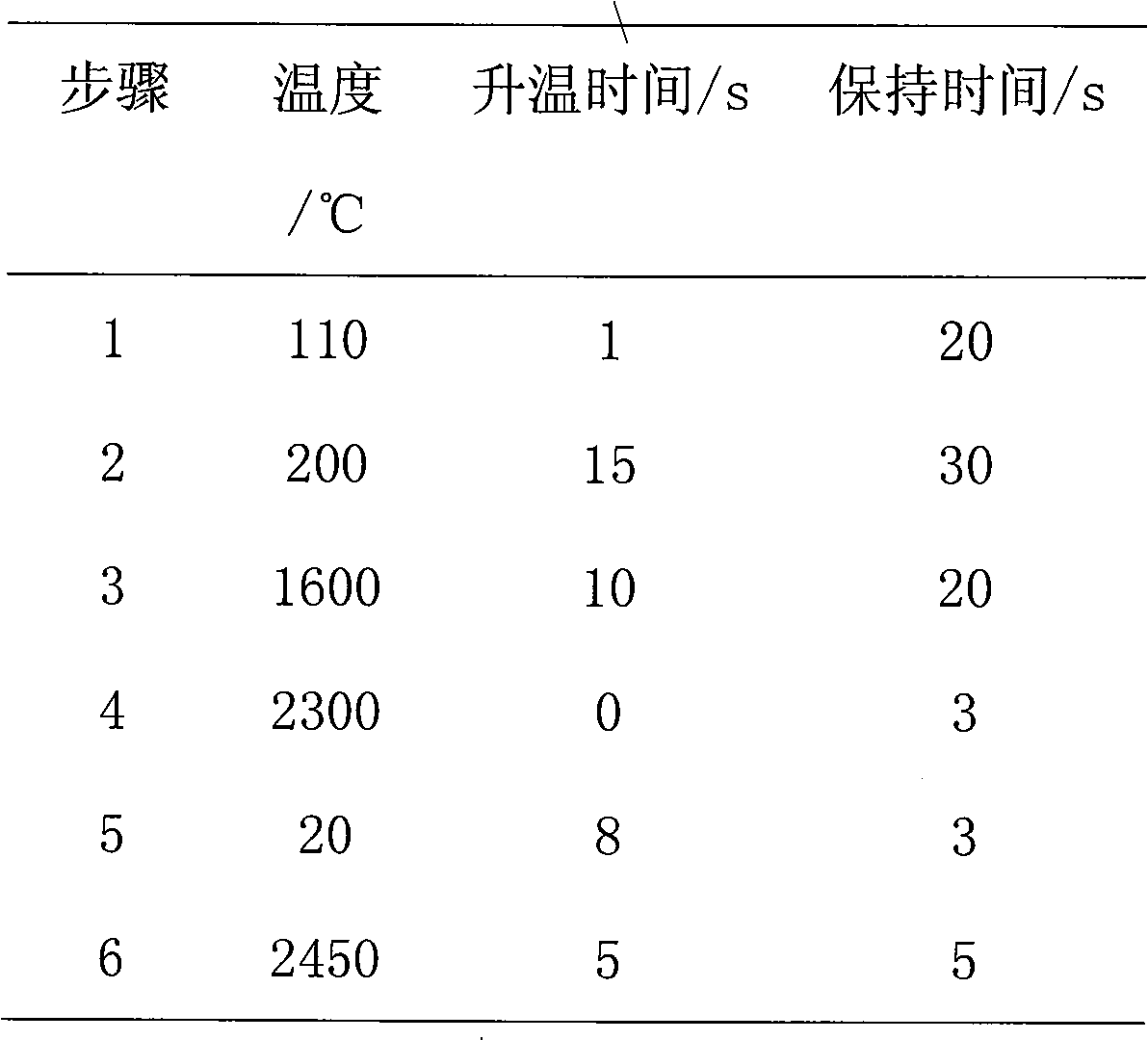

[0024] Using the automatic dilution function of AAS...

Embodiment 2

[0027] The mensuration of arsenic content in the tobacco sample of embodiment 2

[0028] (1) Tobacco samples were pretreated and digested by nitric acid-hydrogen peroxide system microwave to prepare the test solution;

[0029] Weigh 0.2g of dried and pulverized 40-mesh smoke powder sample, put it in a 50mL microwave digestion tank, add 3mL of 68% nitric acid, let it stand at room temperature for 15min, add 1mL of 30% hydrogen peroxide, and cover with a polytetrafluoroethylene inner cover followed by microwave digestion. The digestion procedure is: heating up at 140°C for 2 minutes, holding for 10 minutes; heating up at 170°C for 1 minute, holding for 10 minutes; heating up for 1 minute at 200°C, holding for 10 minutes; cooling for 3 minutes at 100°C, holding for 7 minutes. After the digestion, cool to room temperature, open the tank, transfer the digestion solution to a 25mL volumetric flask, wash the digestion tank with 0.2% (volume fraction, the same below) nitric acid, inc...

Embodiment 3

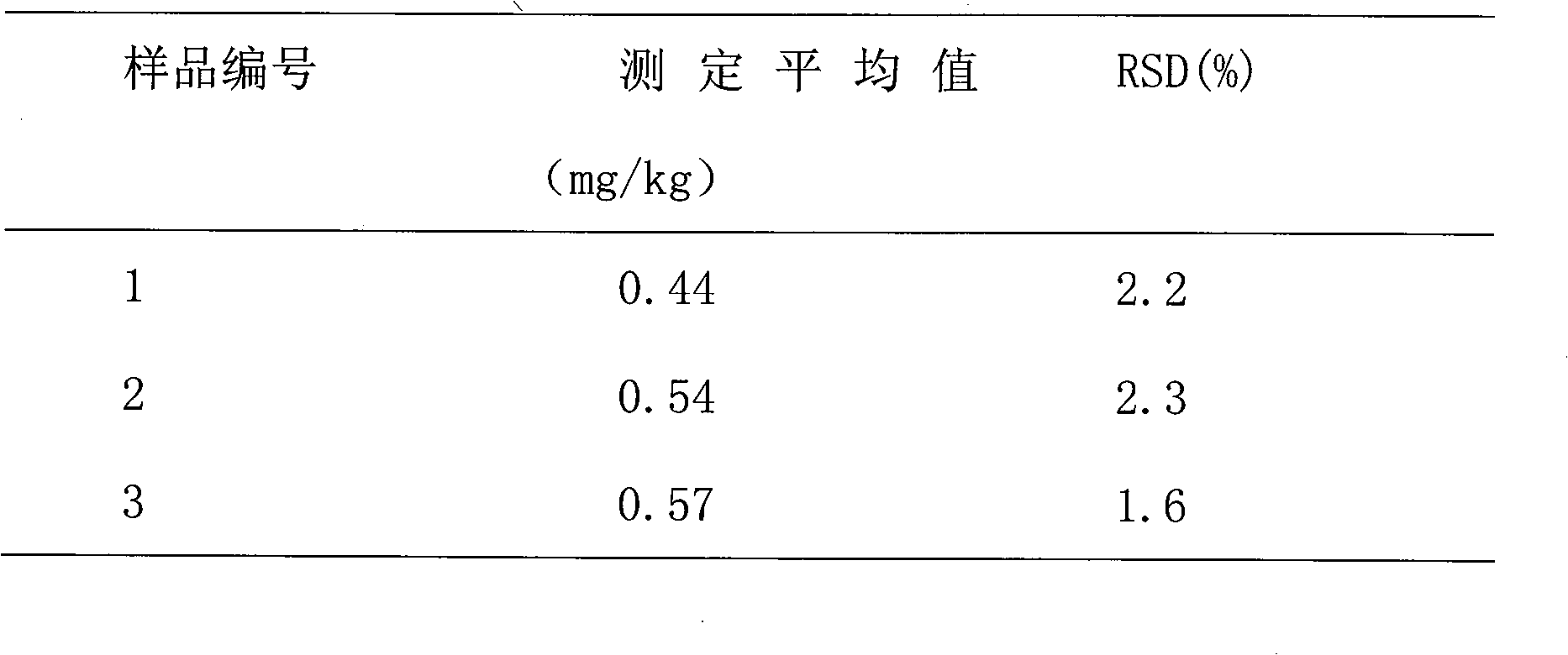

[0035] Embodiment 3 relative phase difference, rate of recovery and repeatability experiment

[0036] Get 2 parallel samples according to the method described in Example 2, adopt the method of the present invention to measure its arsenic content respectively, the recorded arsenic content is respectively 0.44 and 0.46mg / kg, is 0.45mg / kg on average, and relative difference is 4.4%, Meet the requirements of GB / T5009.12-1996 relative difference ≤ 20%.

[0037] Take 3 different samples, all spiked with 5 μg / L, measure their arsenic content respectively, and calculate the recovery rate according to the original content, spiked amount and measured amount, the results are shown in Table 2. It can be seen from Table 2 that the standard addition recovery rate of this method is between 92.0% and 102.0%, indicating that this method has high accuracy.

[0038] The recovery rate of table 2 arsenic

[0039] sample

Numbering

content

(μg / L)

spiked

measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com