A permanent magnetic mechanism

A permanent magnet mechanism, permanent magnet technology, applied in electromagnetic relays, electromagnetic relay details, high-voltage air circuit breakers, etc., can solve the problem of limited power and structural space of closing coils, inability to design electromagnetic coils, and burning of closing coils and other problems, to achieve the effect of simple structure, reliable performance and increased space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

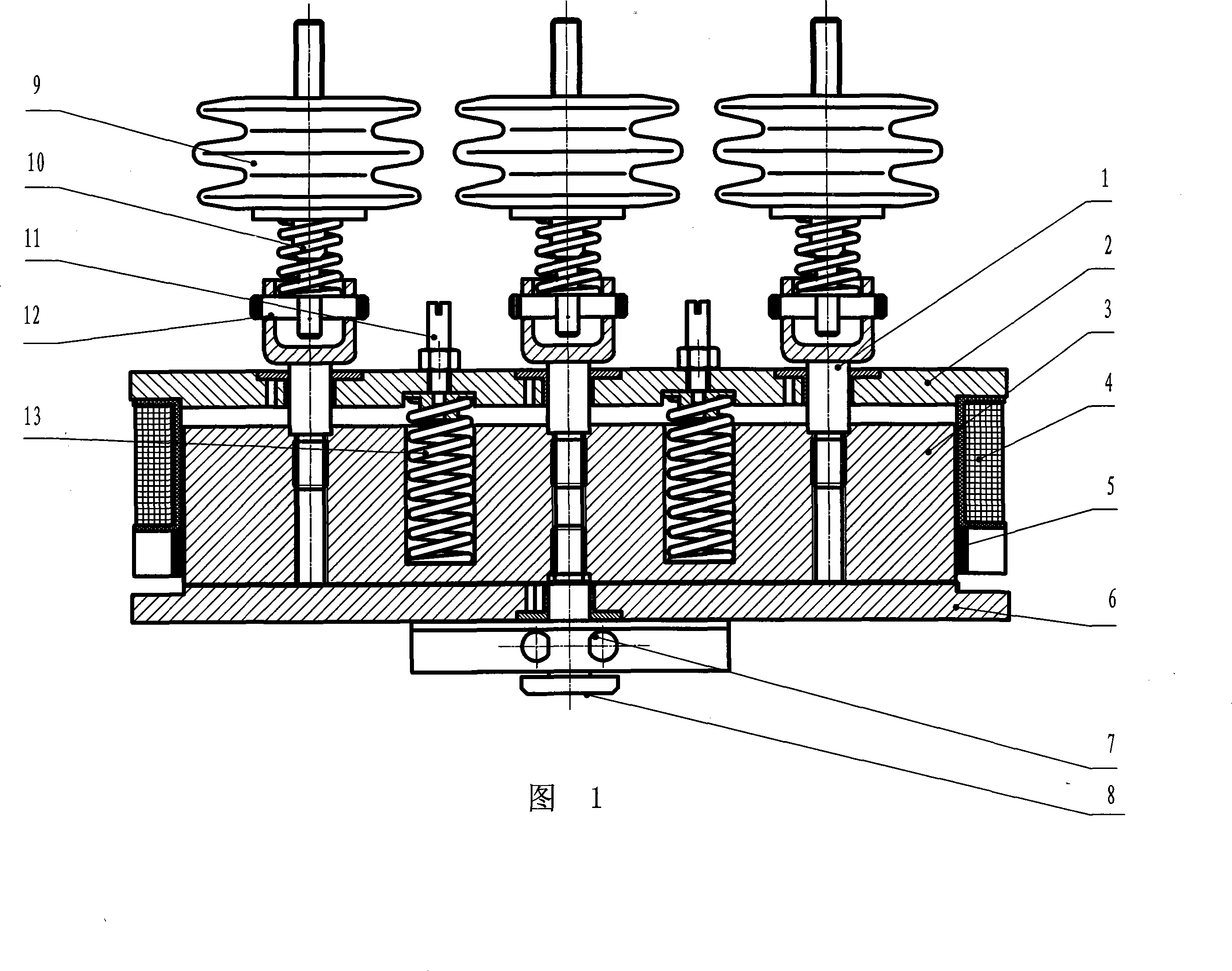

[0010] As shown in the figure, the present invention includes an upper casing 2 and a lower casing 6, and a strip-shaped moving iron core 3 is arranged inside the upper casing 2 and the lower casing 6, and three upper guides are fixed on the upper part of the moving iron core 3. The rod 1 and the upper guide rod 1 pass through the upper housing 2; two opening springs 13 are symmetrically arranged on both sides of the upper guide rod 1 located in the middle on the moving iron core 3, and the upper end of the opening spring 13 is connected with a opening spring The top wire 11, the opening spring 13 can be adjusted and locked through the top wire 11 of the opening spring; the closing coil 4 is set on the moving iron core 3, and the permanent magnet 5 is installed under the closing coil 4, and the permanent magnet mechanism is composed of the above basic components. An insulator 9 and a contact spring 10 are installed on the upper guide rod 1 through a pin shaft 12, and a lower g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com