Method for producing high octane rating low olefin gasoline

A technology of petroleum hydrocarbon and agent-to-oil ratio, applied in the field of catalytic conversion, which can solve the problems of large changes in fluidization state, large changes in oil gas velocity and catalyst density, failure to guarantee fluidization state, mass transfer rate and uniform temperature distribution, etc. , to achieve the effects of small changes in oil and gas velocity and catalyst density, reduced olefin content in gasoline, and stable fluidized state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

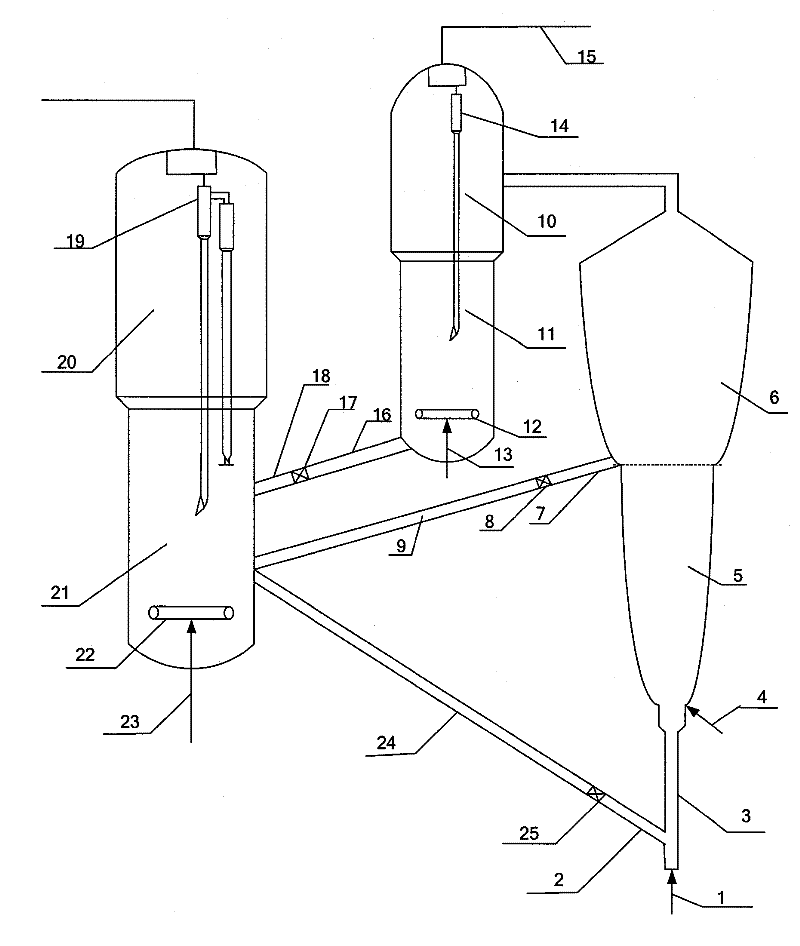

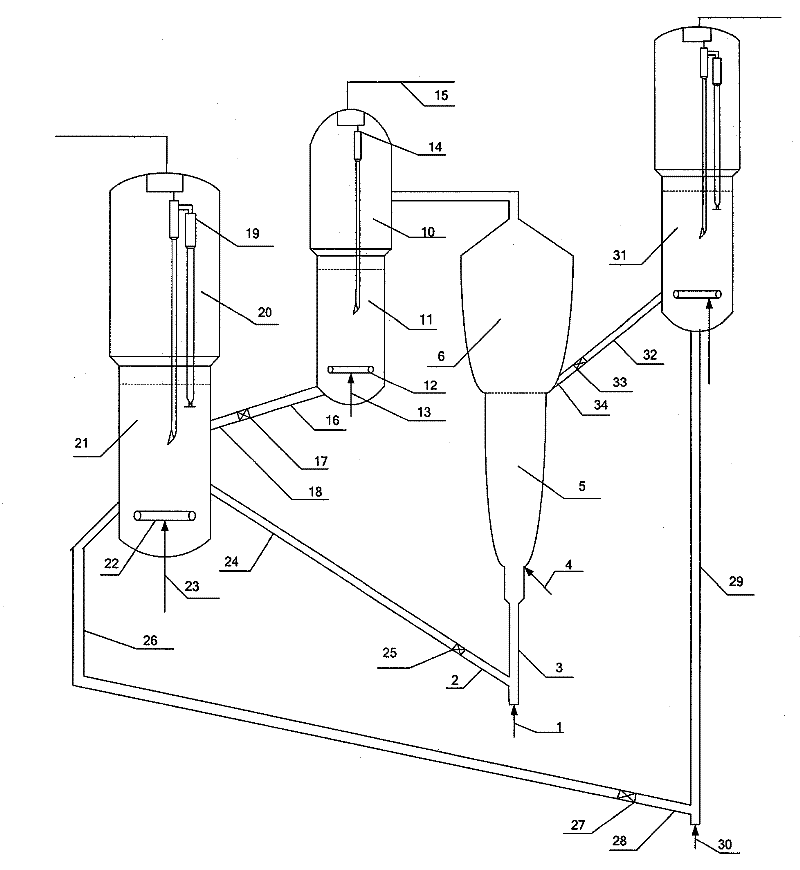

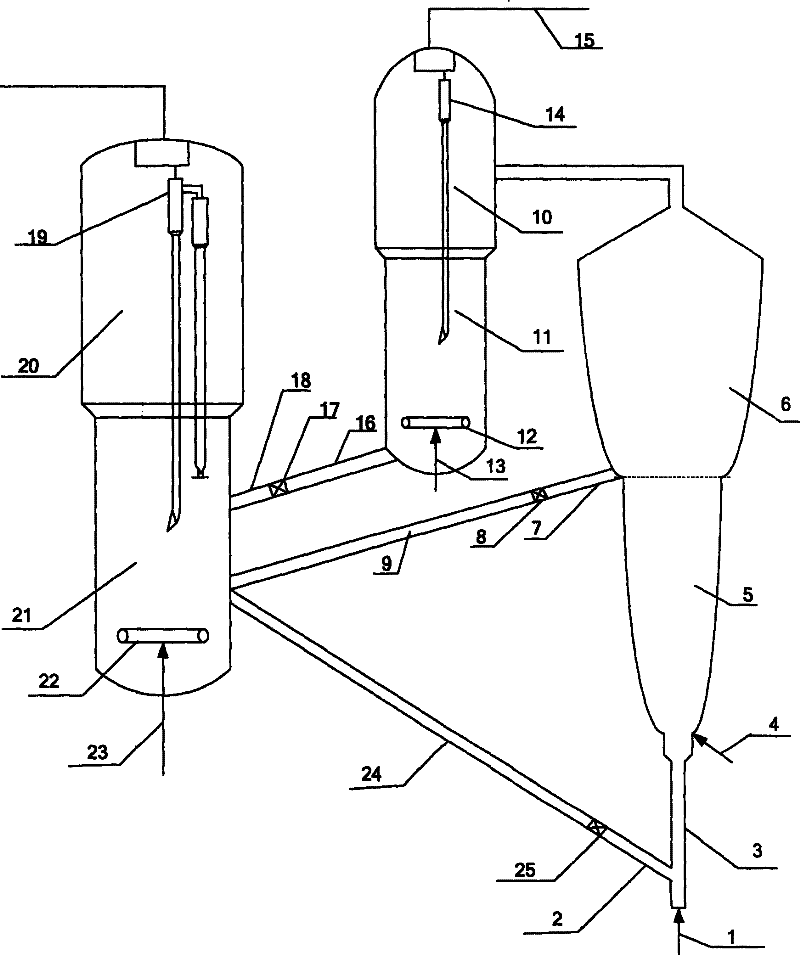

[0045] The reaction system of reactor 1 and reactor 2 used in Example 1 in series, the size of reactor 1 is shown in Table 1, and the size of reactor 2 is shown in Table 2. The reaction process is attached figure 1 Shown: The high-temperature regenerated catalyst from the regenerator contacts the feedstock oil at the bottom of reactor 1 and reacts upwards along the riser reactor, and part of the regenerated catalyst is replenished at the bottom of reactor 2, and the reacted oil gas and catalyst are separated in the settler, separated out The catalyst is stripped by steam and enters the regenerator to burn off the coke carried on it and restore the activity of the catalyst. The regenerated catalyst then enters the bottom of the riser to participate in the reaction. The oil and gas separated in the settler are separated into oil slurry and other oil and gas through the fractionation tower, and the oil slurry is returned to the reactor for re-refining, and the other oil and gas a...

Embodiment 2

[0047] Embodiment 2 adopts the reaction system identical with embodiment 1, and raw material and catalyzer are with embodiment 1, and reaction process is as attached figure 1 Shown, with embodiment 1. Oil products are weighed and analyzed by simulated distillation to calculate the yield of gasoline and diesel. The volume of gas is measured by a gas meter, and the yield is calculated after gas chromatographic analysis. And samples were taken at different positions in the reactor to analyze the composition of the reaction products. The properties of the raw materials used are shown in Table 3, the properties of the catalyst are shown in Table 4, and the operating conditions and product distribution are shown in Table 5.

[0048] As can be seen from Table 5, compared with the comparative example, the dry gas yield decreased by 0.3 percentage points, the liquefied gas yield increased by 1.0 percentage points, the gasoline yield increased by 3.0 percentage points, and the diesel y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com