Radio-frequency coil capable of preventing short circuit

A technology of radio frequency coil and protective wall, applied in the direction of coil, circuit, sputtering coating, etc., can solve the problem of easy short circuit of radio frequency coil, and achieve the effect of not easy to short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

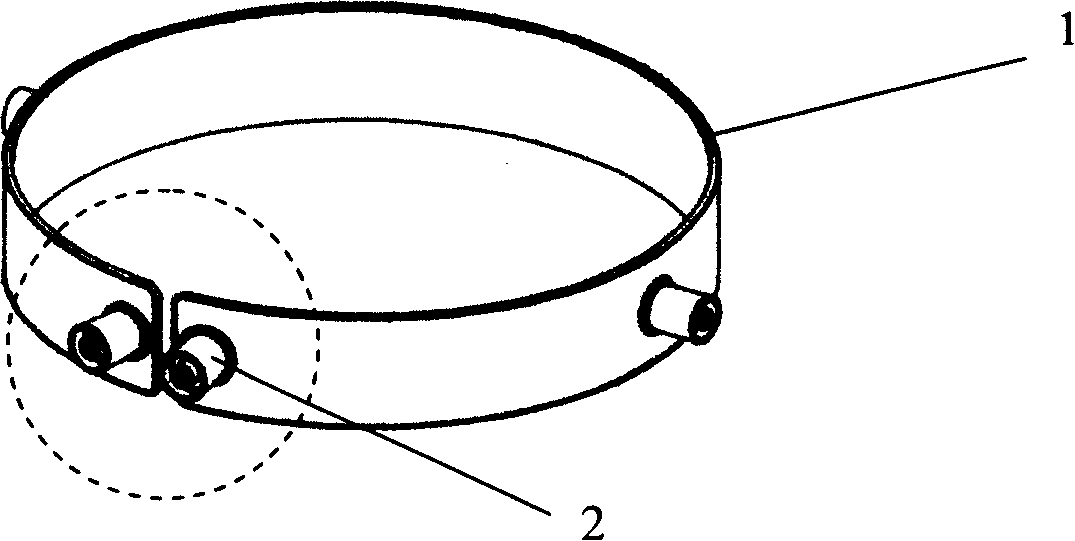

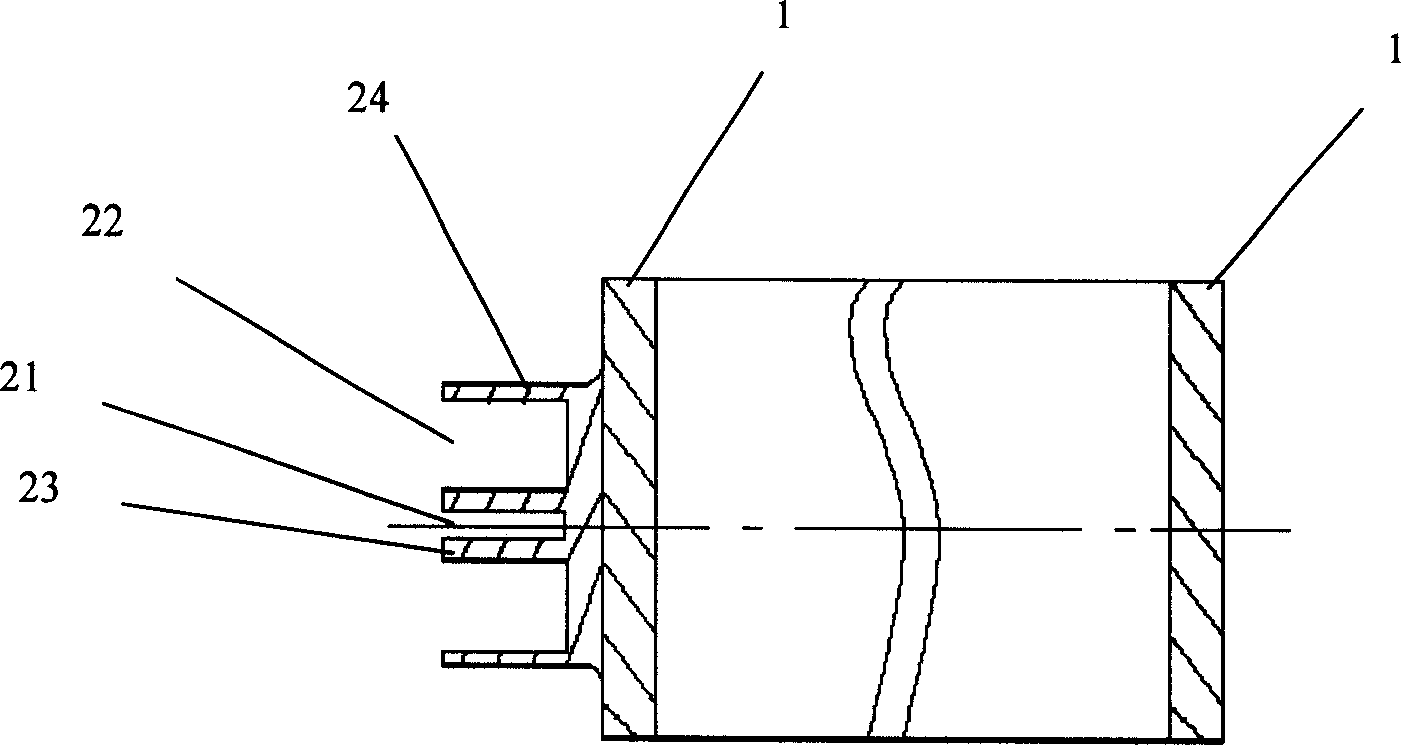

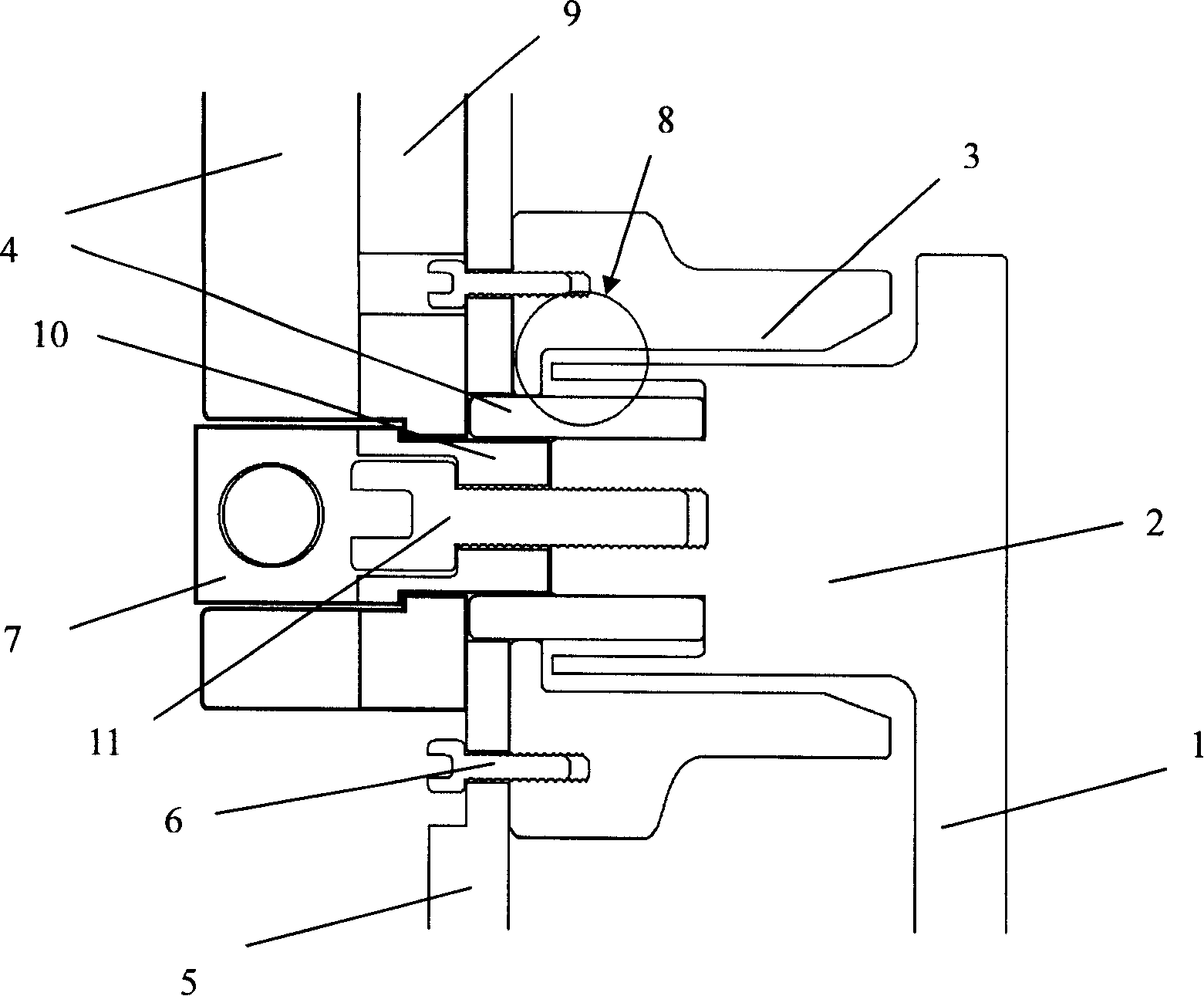

[0051] According to the radio frequency coil of the present invention, such as Figure 5 As shown, it includes: a main body 1 and a connecting part 2 . The connecting part 2 further includes: a central groove 21, an annular groove 22, a central groove wall 23, and an outer wall 24 of the annular groove, wherein the central groove 21 is cylindrical in shape with a depth of 7.874-8.382 mm, and is provided with ribs to cooperate with the bolts. The annular groove 22 is annular with a depth of 7.366-7.874mm. The outer wall 24 of the annular groove is cylindrical and has a height of 5.366-5.874mm. That is, the height of the outer wall 24 of the annular groove is 2mm shorter than that of the central groove 21. Therefore, the process tolerance is 2.686mm.

[0052] The radio frequency coil is used in equipment for forming barrier layers and metal seed layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com