Method and device for auxiliarily proceeding statistic process control in Liquid crystal screen production

A statistical process control and production process technology, applied in computing, special data processing applications, optics, etc., can solve problems such as poor reliability, low work efficiency, low data accuracy, etc., to prevent defects, solve low efficiency, improve accuracy and The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

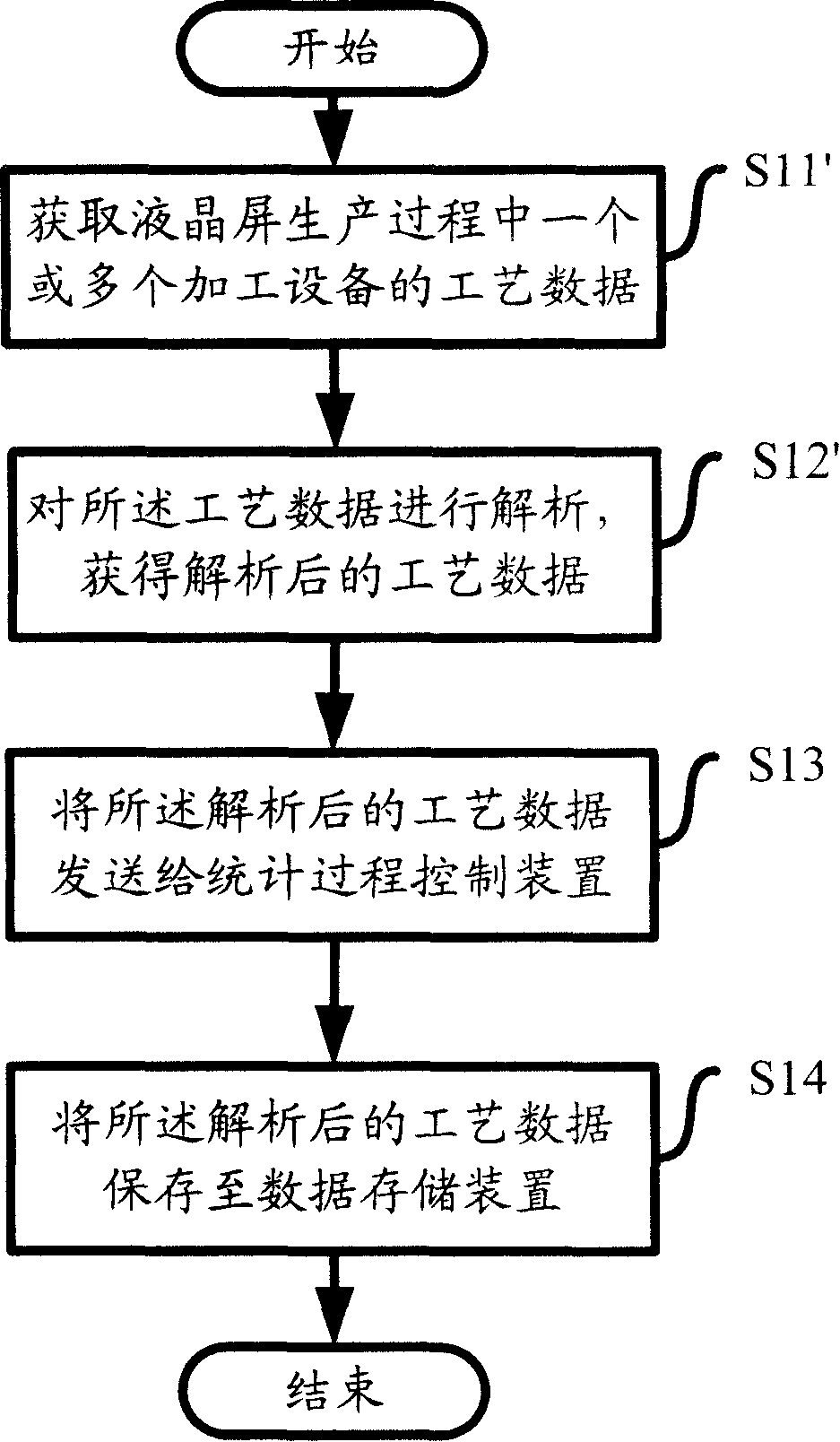

[0049] refer to figure 1 , which describes a flow chart of a method for assisting statistical analysis process control in the liquid crystal panel production process according to the first embodiment of the present invention. First, step S11' is executed to obtain the process data of one or more processing equipment in the production process; then enter step S12' to analyze the process data to obtain the analyzed process data; then execute step S13 to The analyzed process data is sent to the statistical process control device; finally step S14 is executed to save the analyzed process data to the data storage device.

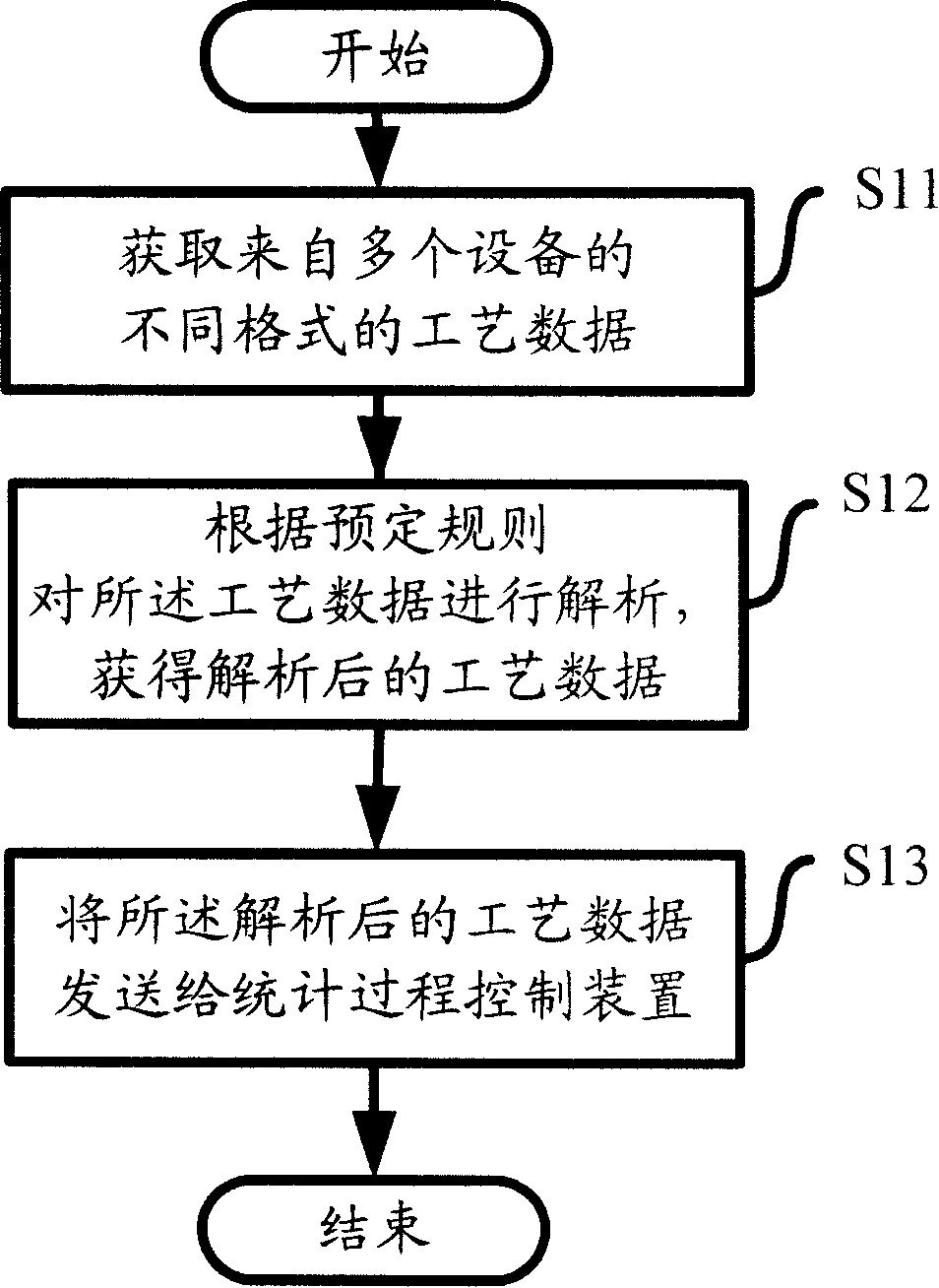

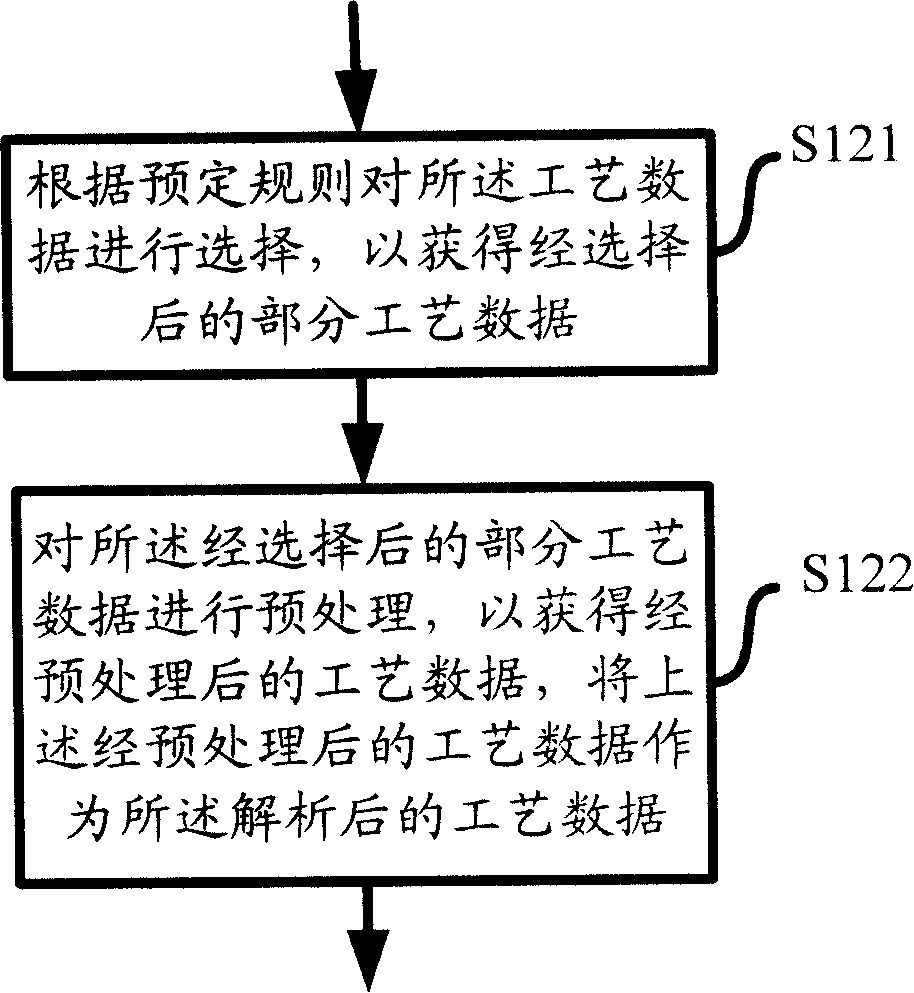

[0050] refer to figure 2 , which describes a flow chart of a method for assisting statistical analysis process control in the liquid crystal panel production process according to the second embodiment of the present invention. First execute step S11 to obtain process data in different formats from multiple devices; then execute step S12 to analyze the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com