Coiling mould eccentric rotation-proof winding device

A winding device and winding die technology, which is applied in coil manufacturing, transportation and packaging, electrical components, etc., can solve the problems of complex manufacturing process, easy wear of planetary gears, machining accuracy, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

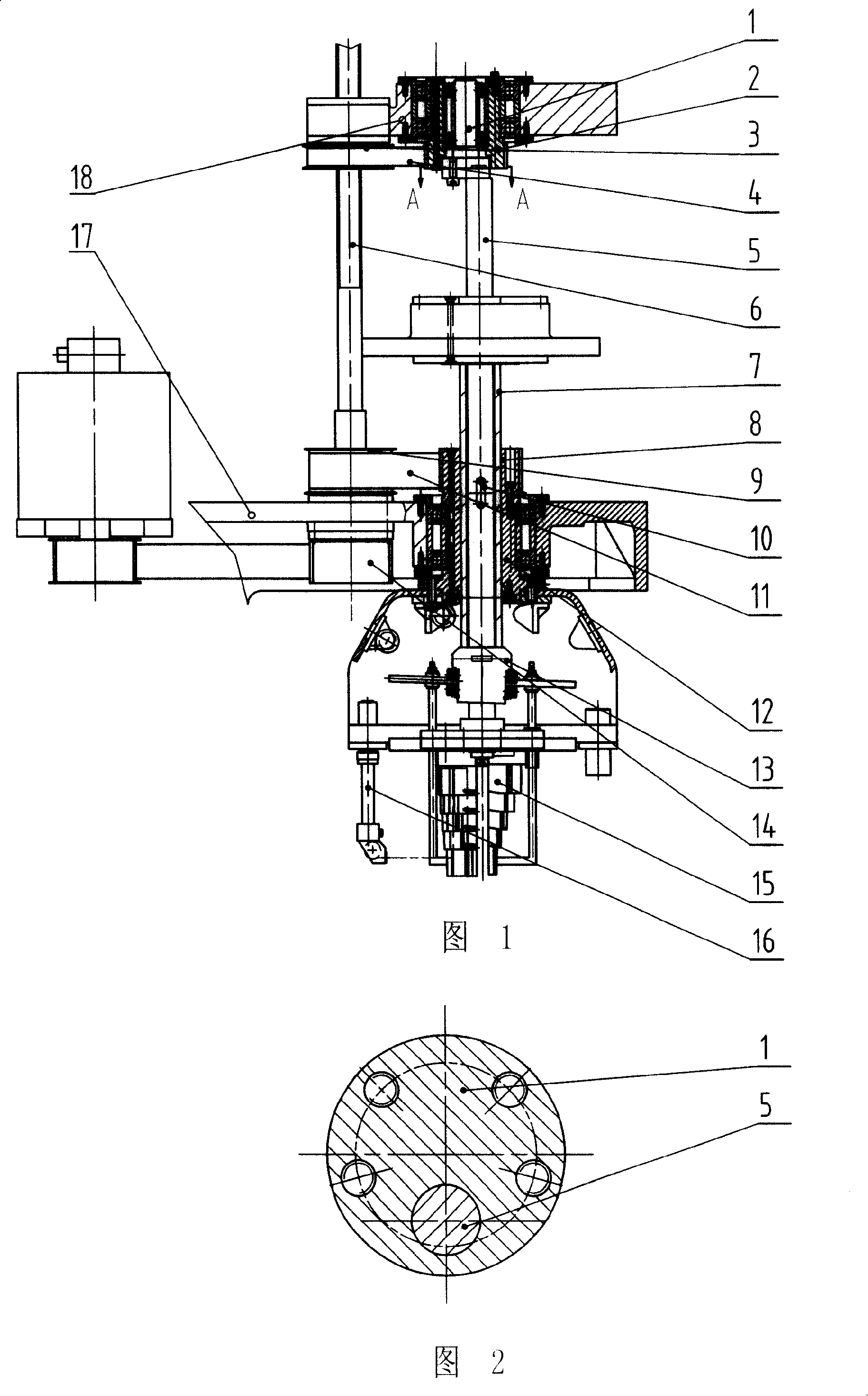

[0010] Refer to Figures 1-2. 1. An eccentric anti-rotation winding device for winding molds, the winding mold 15 is fixedly connected to the lower part of the hanging mold shaft 5 on the frame 17, and the wire pushing sleeve 7 is set on the hanging mold shaft 5 and the eccentric cam cable pushing wire at the lower end The mechanism is fixedly connected, and a spline shaft 6 is set on the frame at the side of the hanger shaft 5, and its outer circle is slidingly matched with the inner hole of the timing pulley 3, and the slider 18 is connected with the timing pulley 3 through a bearing and located on the spline shaft 6 The outer diameter of the connecting shaft 1 is installed on the inner hole of the synchronous pulley 2 through the bearing, and the outer diameter of the synchronous pulley 2 is installed on the slider through the bearing; The end surface is provided with an eccentric boss, and the lower end surface of the connecting shaft 1 is provided with an eccentric groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com