Multifunctional support for automobile

A multi-functional, automotive technology, applied in vehicle components, jet propulsion, internal combustion propulsion, etc., can solve the problems of inability to effectively integrate the powertrain, insufficient rigidity of the powertrain, and reduced volume, etc. Lightweight structure and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

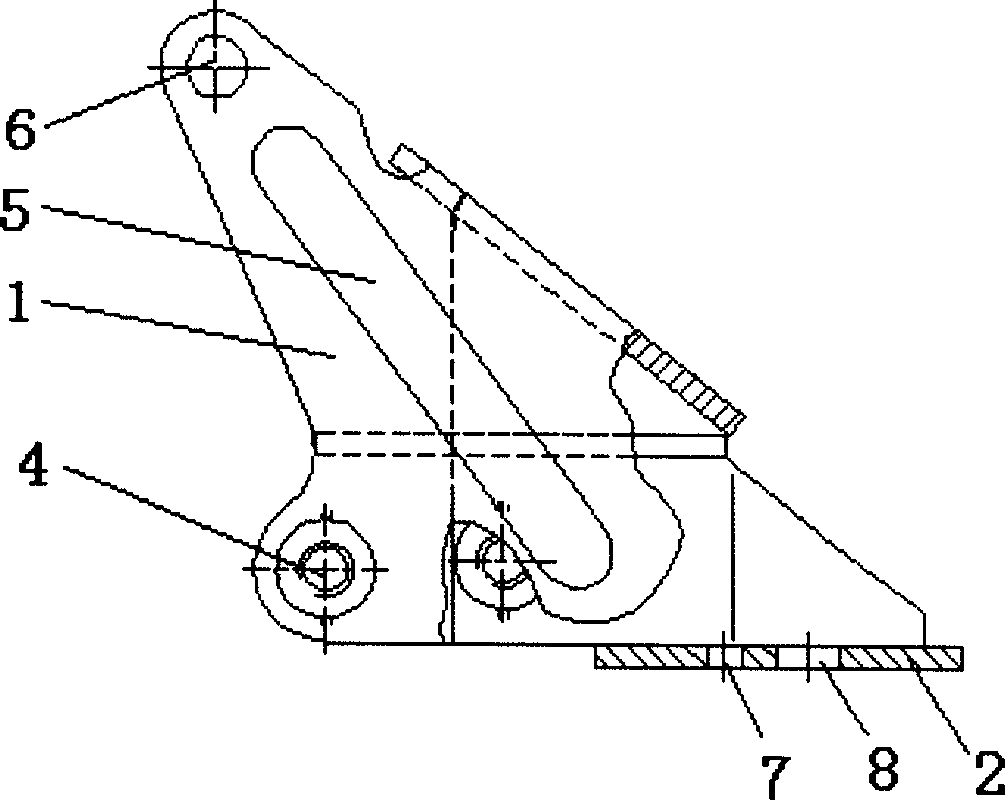

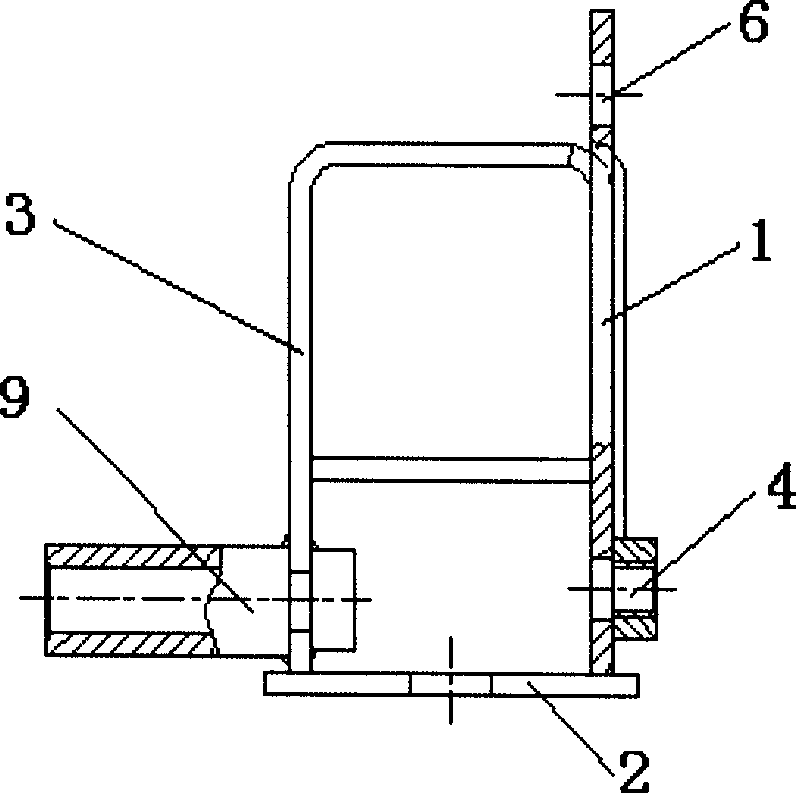

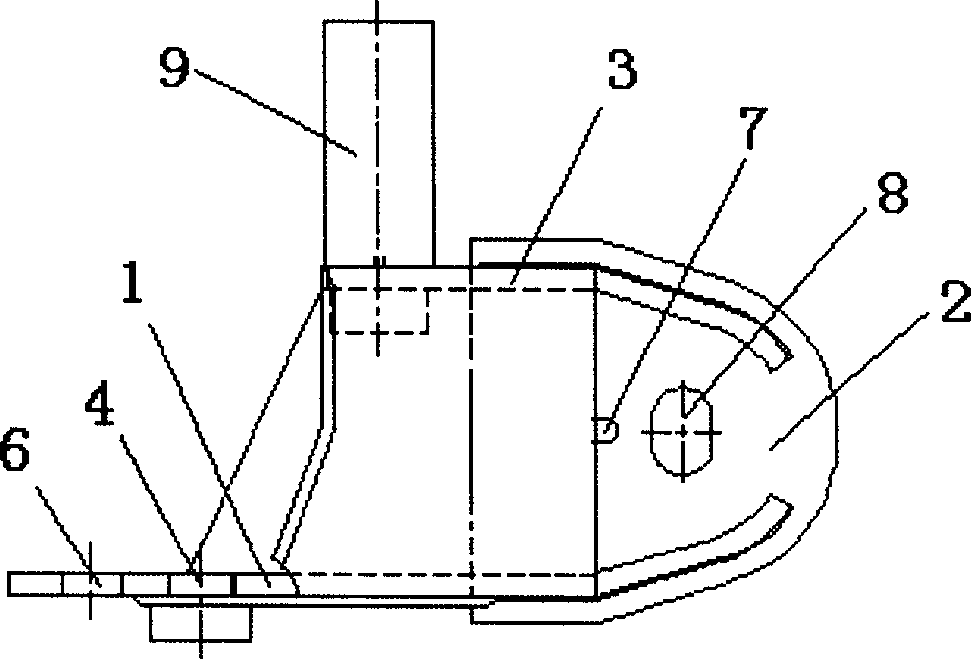

[0012] exist figure 1 , 2 and 3, a multifunctional bracket for a vehicle, which is a metal structural component bracket made by stamping and welding. Including the lower side plate 2, the lower side plate 2 is provided with a fourth hole 8 and a third hole 7 for installation and positioning respectively, and is connected with the suspension cushion assembly, which can effectively limit the relative displacement between the bracket and the cushion . The front end of the lower side plate 2 is provided with the front side plate 1 , and the rear end of the lower side plate 2 is provided with the rear side plate 3 . The second hole 6 and the first hole 4 are provided on the front side plate 1, which are respectively a connection and installation point of the engine and the gearbox, which can significantly increase the first-order bending mode of the powertrain. The fifth hole 9 is set on the rear side plate 3, which is an installation and fixing point of the starter.

[0013] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com