Epoxy resin shape memory polymer material and method for producing the same

A polymer material and epoxy resin technology, applied in the field of shape memory materials, can solve problems such as difficulty in realizing saturated shape memory effect, difficult adjustment of thermal response temperature, slow shape recovery rate, etc., to achieve convenient preparation, fast shape recovery rate, The effect of short thermal response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

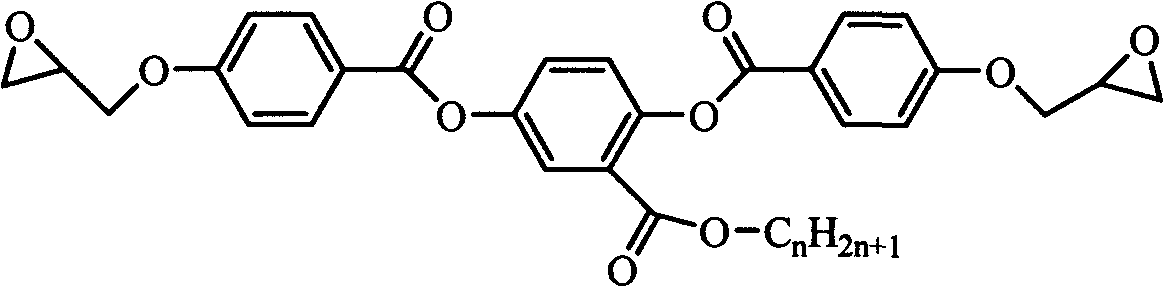

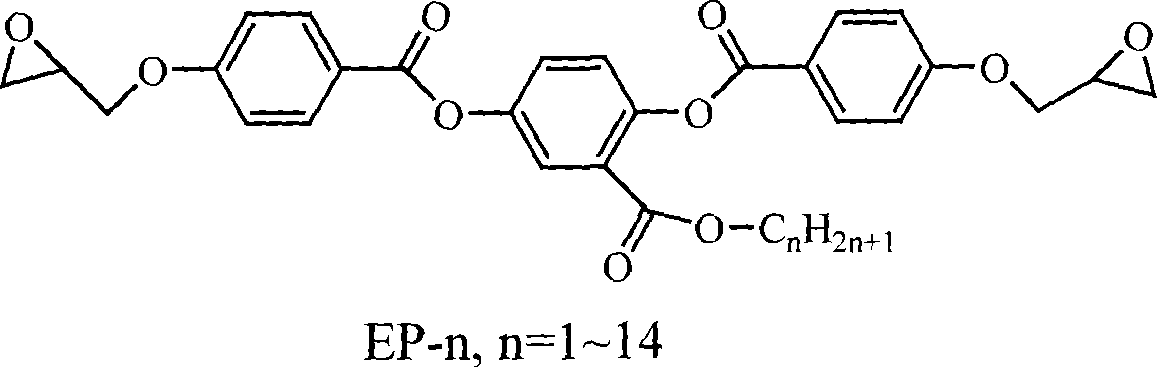

[0020] Take liquid crystal epoxy resin monomer EP-1 and curing agent 4,4'-diaminodiphenylmethane according to the stoichiometric ratio, dissolve and mix with dichloromethane, pre-cure at 120°C for 5 hours under vacuum, then medium temperature at 160°C Curing for 5 hours and post-curing at 200° C. for 1 hour to obtain an epoxy resin shape memory polymer material. The thermal response temperature of the obtained epoxy resin shape memory polymer material was measured to be 153°C.

Embodiment 2

[0022] Take liquid crystal epoxy resin monomer EP-2 and curing agent methyl hexahydrophthalic anhydride according to stoichiometric ratio, dissolve and mix with dichloromethane, add curing accelerator benzyldimethylamine of 1% of the total mass of monomer and curing agent , pre-cured at 115°C for 6 hours in vacuum, then cured at medium temperature at 160°C for 5 hours, and post-cured at 200°C for 1 hour to obtain an epoxy resin shape memory polymer material. Its thermal response temperature is 134°C.

Embodiment 3

[0024] Take liquid crystal epoxy resin monomer EP-14 and curing agent methyl hexahydrophthalic anhydride according to stoichiometric ratio, dissolve and mix with dichloromethane, add curing accelerator DMP-30 of 1% of the total mass of monomer and curing agent, vacuum Pre-cure at 50°C for 12 hours, then cure at medium temperature at 160°C for 5 hours, and post-cure at 200°C for 1 hour to obtain an epoxy resin shape memory polymer material. Its thermal response temperature is 54°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com