Full-automatic dynamic quality detecting system for goods train bearing

A railway freight car and detection system technology, which is used in railway vehicle testing, mechanical bearing testing, vibration testing, etc., can solve the problem of lack of means to detect the dynamic quality of railway freight car bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

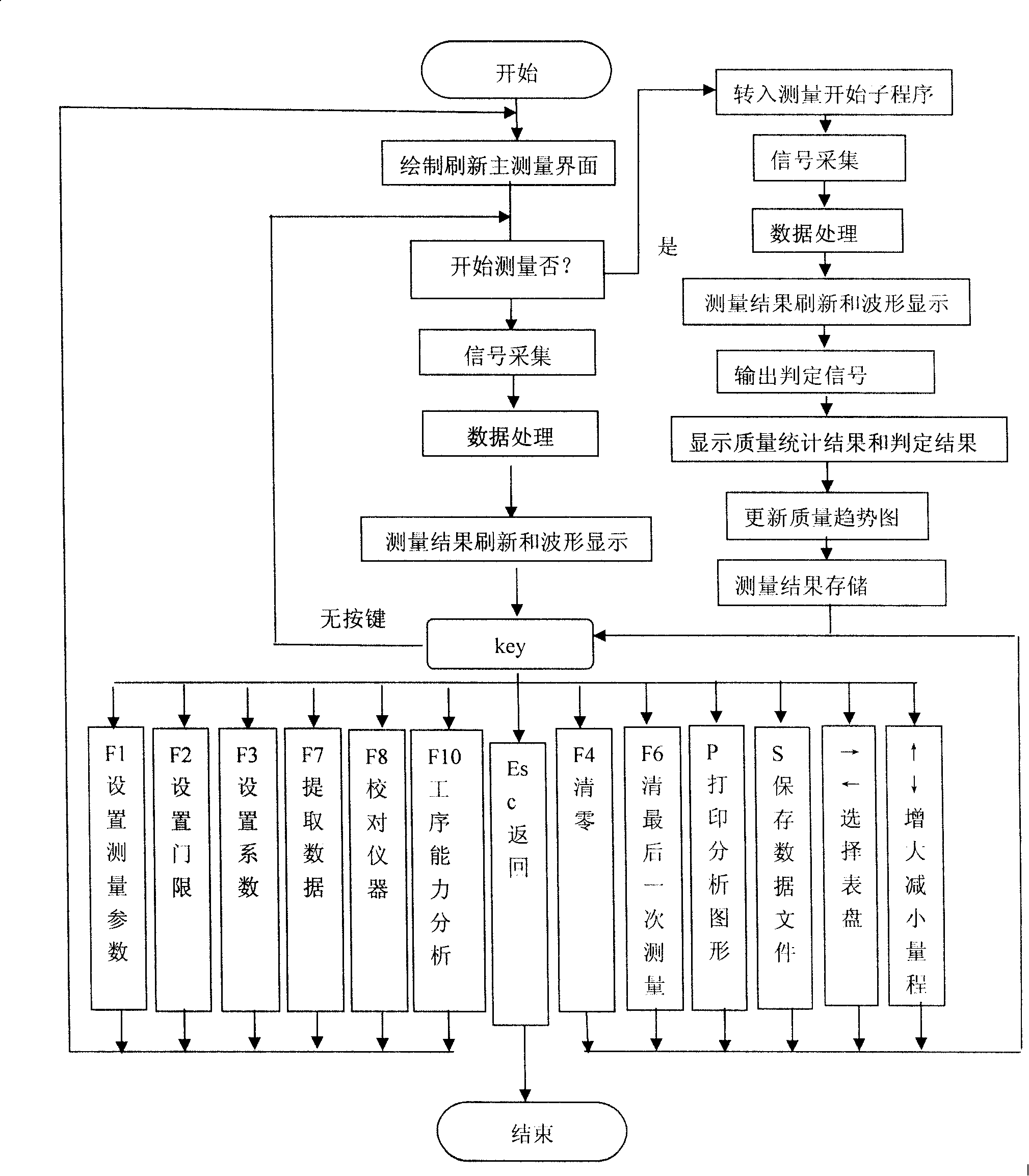

[0081] In order to make the hardware work, the application program is written in C language, the general program block diagram is shown in image 3 ;

[0082] 1) After starting up, the program draws the main measurement interface according to the predetermined plan, see Figure 4 ;The main interface is divided into 16 areas, and the functions of each area are as follows:

[0083] 1. Other measurement parameter area: respectively display the crest factor and kurtosis value measured at the front and rear (I, II) stations

[0084] 2. Quality statistics area: display the total number of measurements, the total pass rate and the pass rate of groups A1, A2, A3H and A4 respectively.

[0085] 3. Threshold area: display low, medium and high frequency threshold values.

[0086] 4. Judgment area of the quality level of the front (I) station: according to the measurement results of the front station, the achieved quality level is displayed.

[0087] 5. Rear (II) station quality level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com