Ultra-high frequency electronic label for metallic material surface

A technology of electronic tags and metal materials, which is applied to record carriers used in machines, instruments, computer parts, etc., can solve the problems of high cost of ferrite materials and unfavorable promotion of RFID products, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

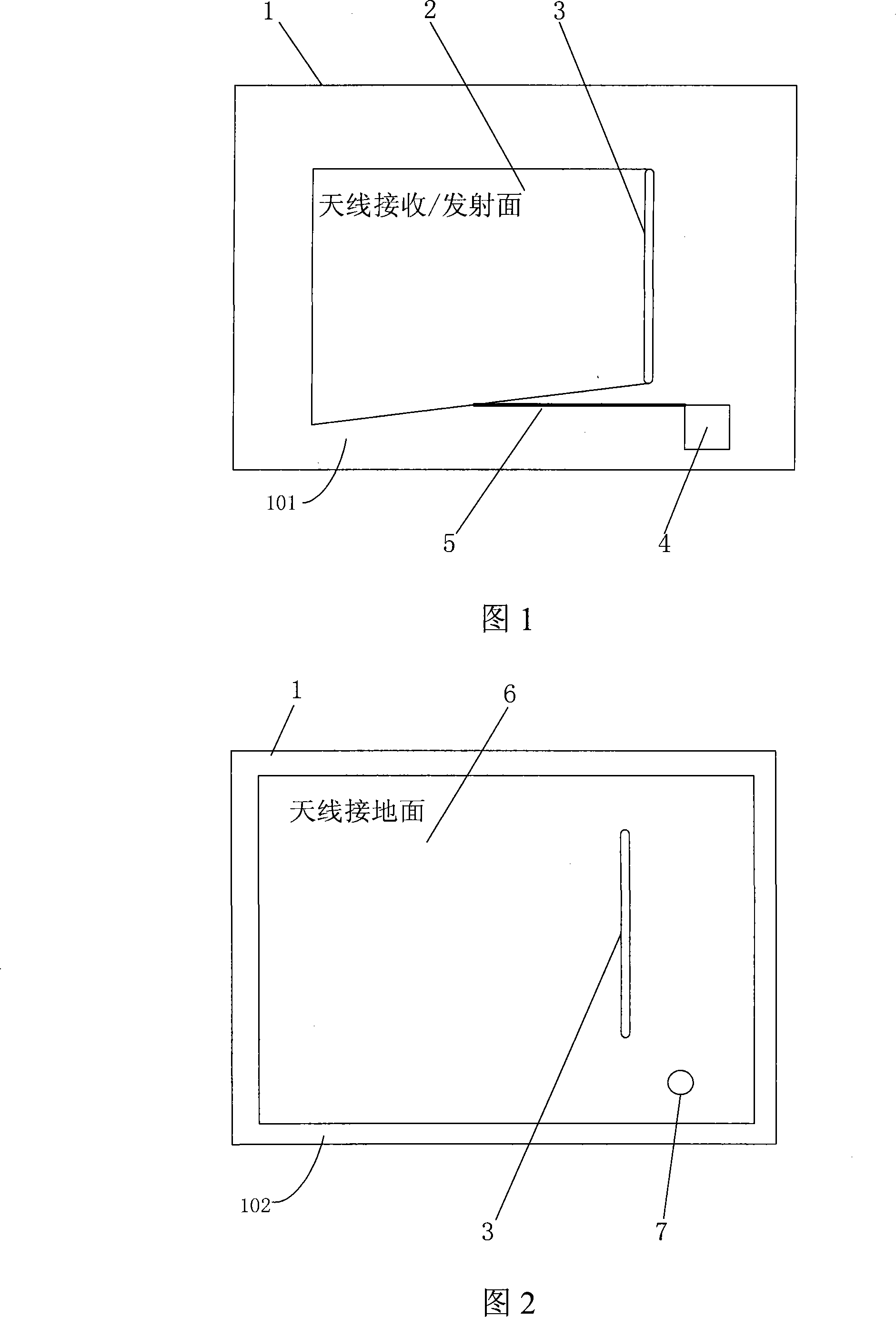

[0020] The structural features of the RFID of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] As shown in Figures 1 and 2, the RFID of the present invention includes: a substrate 1, a chip 4 of an electronic label placed on the substrate 1, a feeder 5 connected to the chip 4, and a microstrip antenna, which is received / emitted by the antenna Surface 2 (shown in Figure 1), antenna ground plane 6 (shown in Figure 2) and feeder 5 (shown in Figure 1). The receiving / transmitting surface 2 of the antenna is placed on the side on which the chip 4 and the feeder 5 are placed on the substrate 1, and this substrate surface is the front side 101 of the electronic label (shown in Figure 1); the antenna grounding surface 6 is placed on the side of the substrate 1 On the other hand, this substrate surface is the back side 102 (shown in Figure 2) of the electronic label; the antenna receiving / transmitting surface 2 is connected wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com