Low-melting point alloy wire and temperature fuse adopting the same

A thermal fuse and alloy wire technology, applied in emergency protection devices, electrical components, circuits, etc., can solve the problem of high resistivity of alloy wire, achieve the effect of improving the accuracy of fusing temperature and eliminating the uncertainty of fusing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

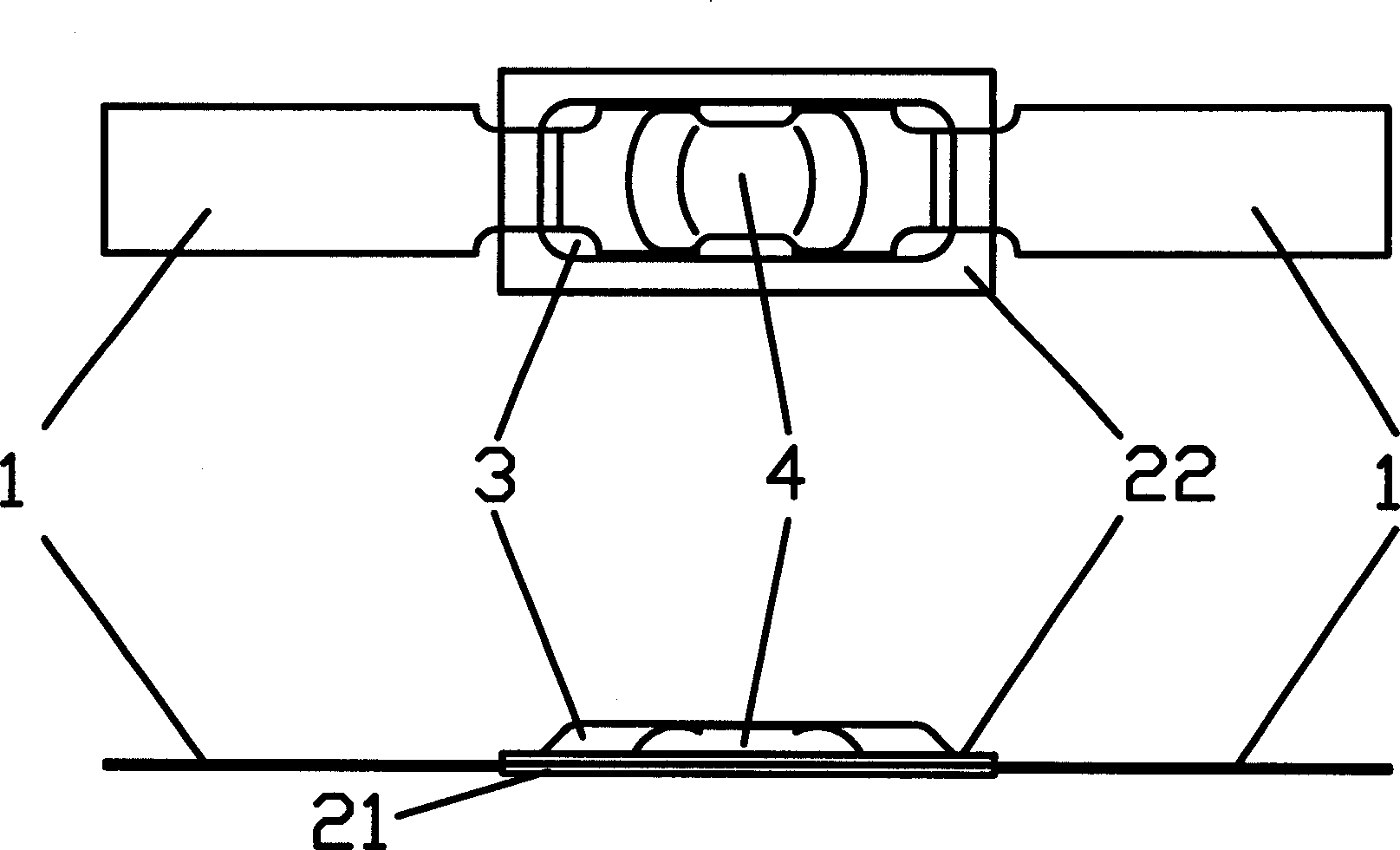

Image

Examples

Embodiment 1

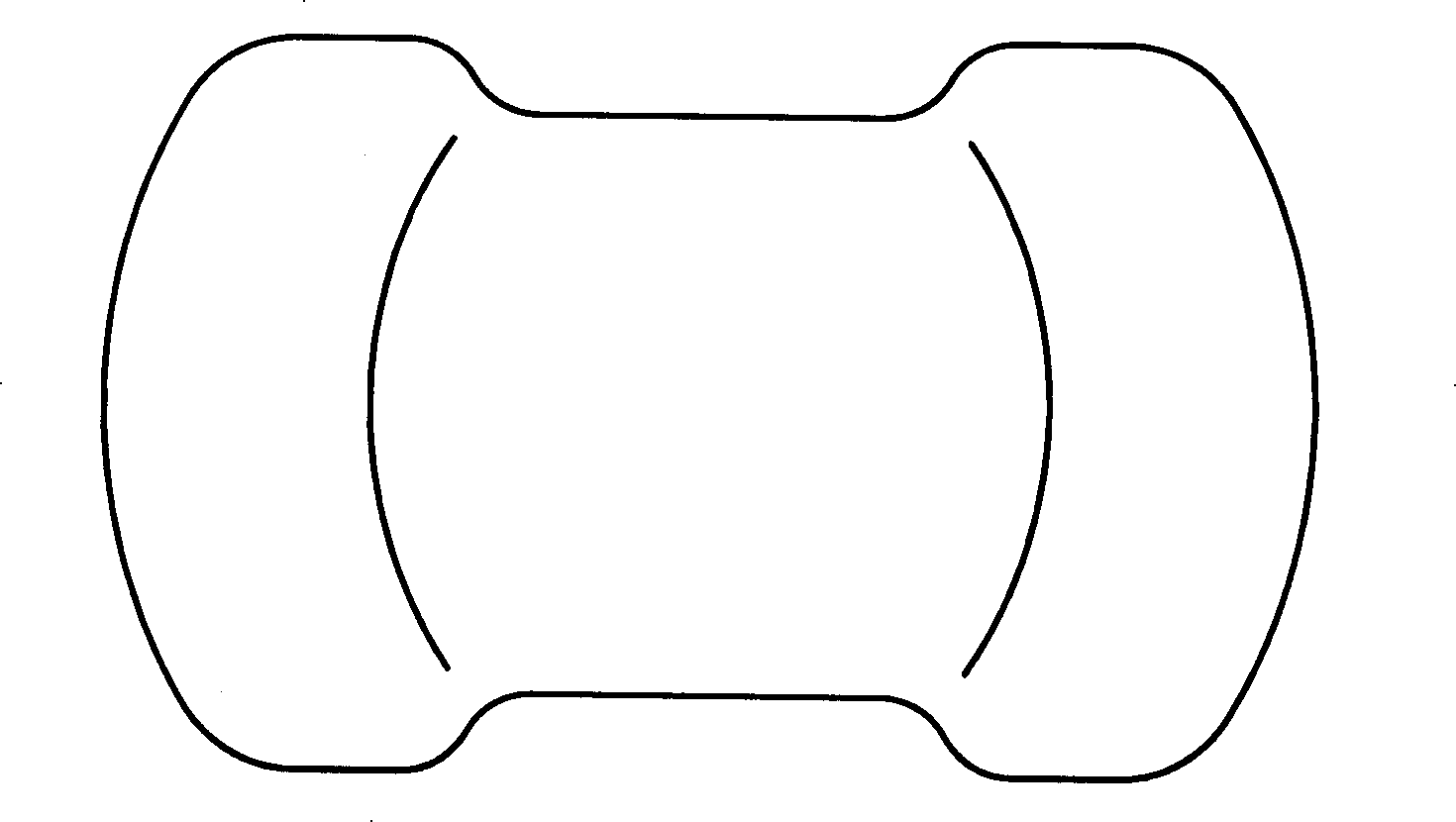

[0034] The cross-sectional area of the molded low melting alloy wire (4) of the present invention is 1.13mm 2 , The diameter of the raw material is 1.2mm, and the main components are In52%, Sn31%, Bi13%, Ag1%, Cu1%, and Zn2%.

[0035] The flux of the present invention is prepared according to the following process: Weigh 6g stearic acid and add it to 10g n-butanol, put it in a thermostat at 120°C until it dissolves, then add 20g hydrogenated rosin and 10g disproportionated rosin, stir and mix evenly , Put it in a heating furnace and heat it until it boils, take it out and add 1 g of glacial acetic acid until it cools to room temperature, spot the above flux on the cover film with a dispenser, and ultrasonically weld it to form.

Embodiment 2

[0037] The cross-sectional area of the low melting point alloy wire (4) after molding of the present invention is 1.33mm 2 , The diameter of the raw material is 1.3mm, and the main components are In54%, Sn35%, Bi8%, Ag1%, Cu2%. The test method is the same as in Example 1.

[0038] Weigh 6.5g stearic acid into 10g n-butanol, put it in a thermostat at 120°C until it dissolves, then add 15g disproportionated rosin and 15g polymerized rosin, stir and mix evenly, put it in a heating furnace and heat until boiling. After taking it out, add 1 g of glacial acetic acid until it is cooled to room temperature. The other preparation processes are the same as in Example 1.

Embodiment 3

[0040] The cross-sectional area of the invented low melting point alloy wire (4) after molding is 1.33mm 2 , The diameter of the raw material is 1.3mm, and the main components are In50%, Sn33%, Bi15%, Cu1%, Zn1%. The test method is the same as in Example 1.

[0041] Weigh 6g of stearic acid and add it to 10g of positive alcohol, put it in a thermostat at 120°C until it dissolves, then add 25g of ordinary rosin, stir and mix evenly, put it in a heating furnace and heat until it boils, take it out and add 1g of hydrochloric acid Until it is cooled to room temperature, other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com