High voltage dust removal top rapping control main circuit based on PWM technology

A PWM technology, high-voltage dust removal technology, applied in the controller with pulse train output signal, power supply technology, electric controller and other directions, can solve the problems of low control accuracy, frequent system maintenance, short service life, etc. Good power supply overcurrent protection function, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

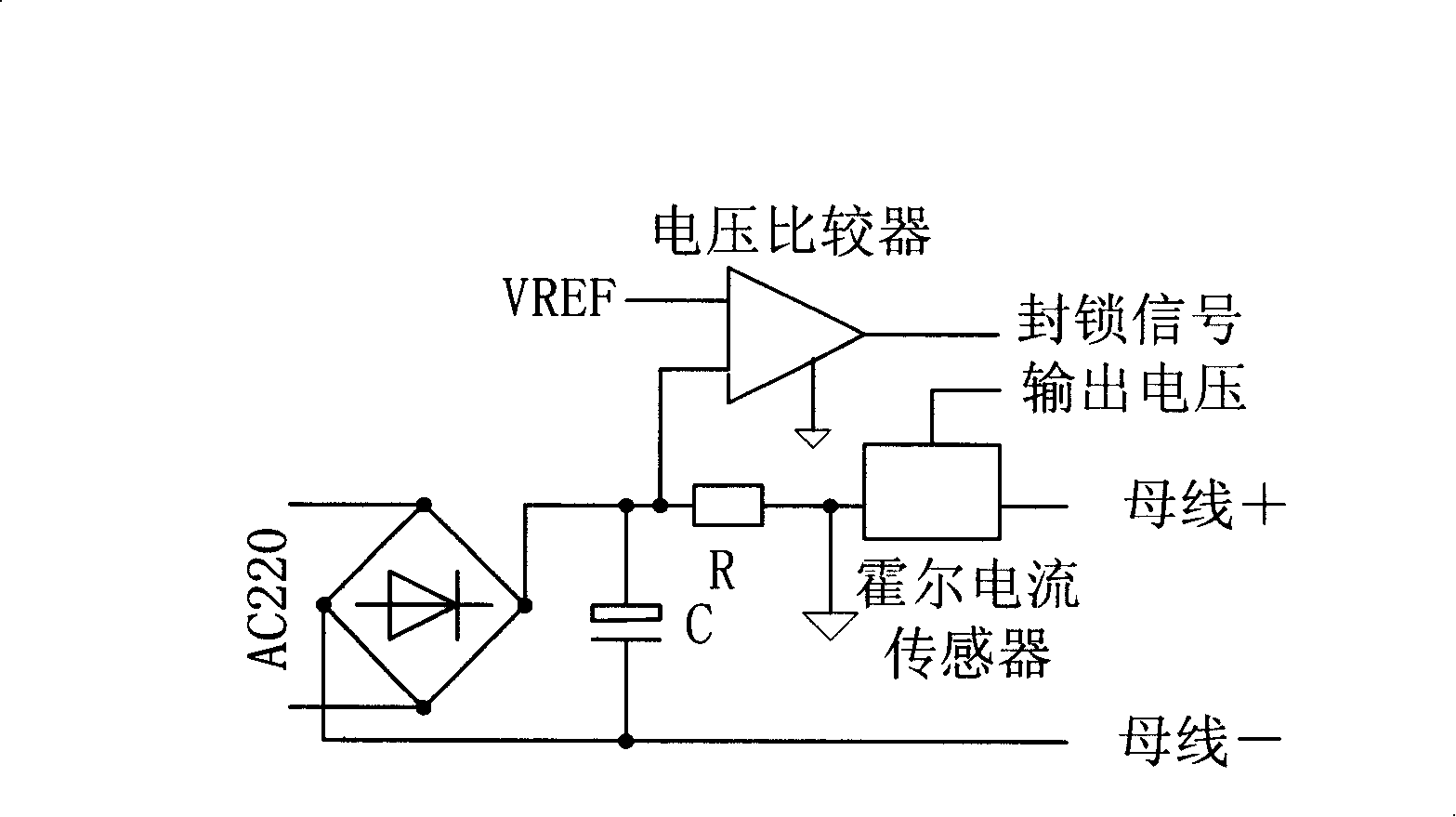

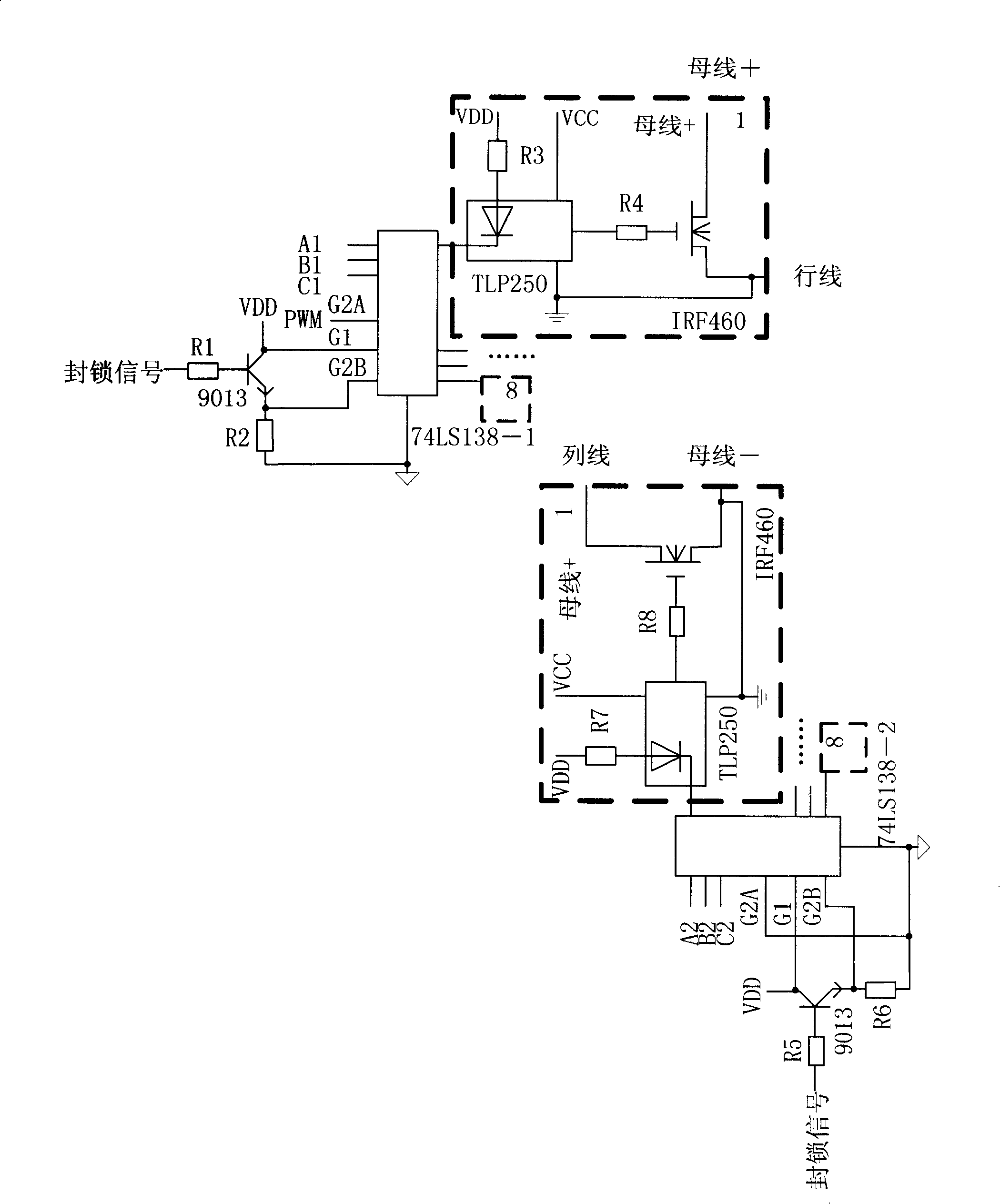

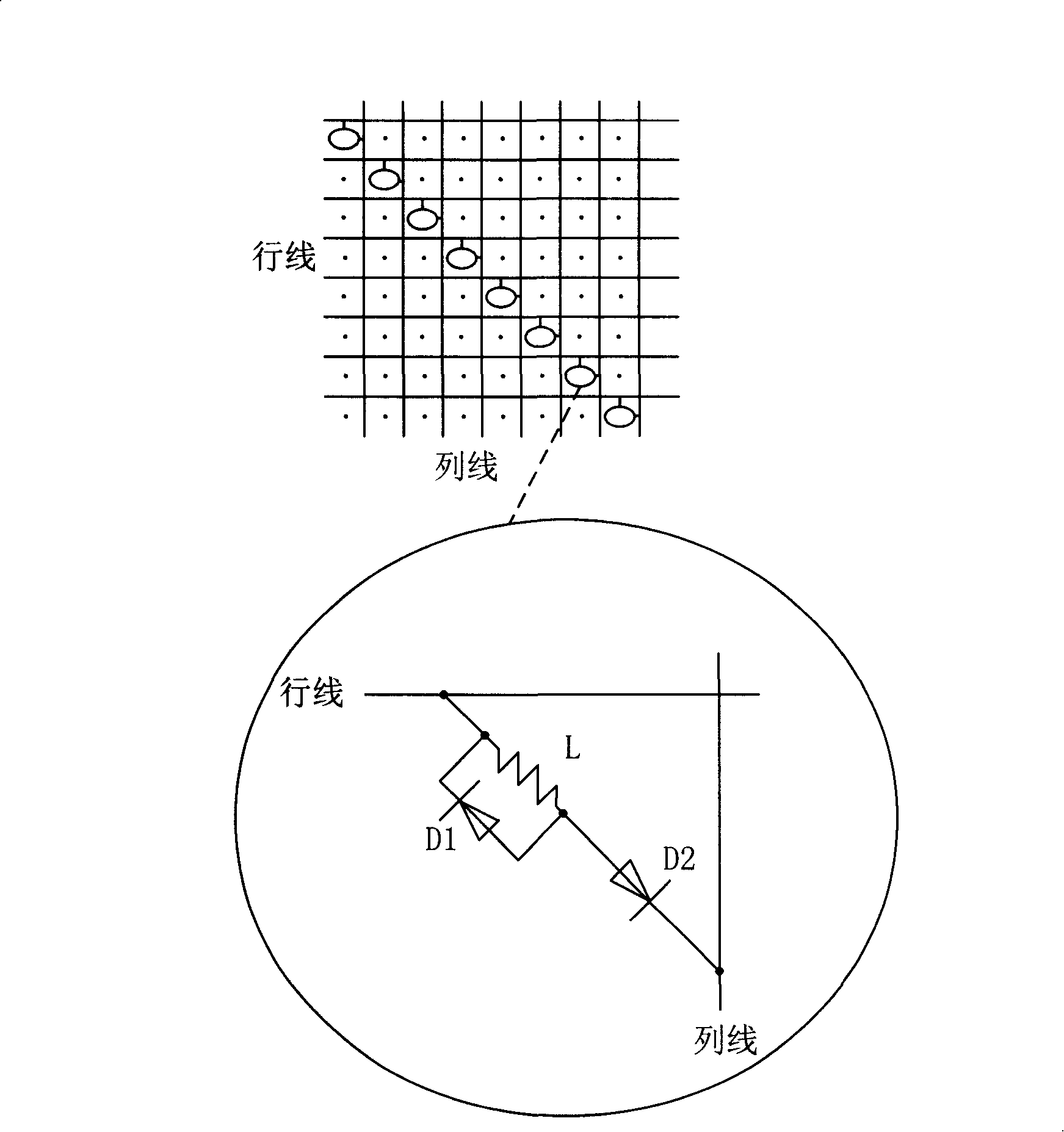

[0017] refer to figure 1 , figure 2 , image 3 , a high-voltage dust removal top rapping control main circuit based on PWM technology, including a power supply circuit, a pulse rapper control circuit, and a rapper matrix. The power supply circuit includes a bridge rectifier circuit connected to an AC power supply, a filter capacitor C and sampling resistance R, the described pulse rapper matrix is an 8×8 pulse rapper matrix; the described rapping control circuit also includes a PWM pulse row and column distribution circuit, and the described PWM pulse row and column distribution The drive circuit includes a row allocation isolation drive sub-circuit, a column allocation isolation drive sub-circuit,

[0018] The row allocation isolation driving sub-circuit includes a three-eight decoder 74LS138, an optocoupler driver chip TLP250 and a field effect transistor IRF46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com