Control system of dual frequency converting wire drawing machine

A control system, double frequency conversion technology, applied in control/regulation system, electric speed/acceleration control, non-electric variable control, etc. Reduce worker workload and improve the effectiveness of automated control procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention are described in detail below.

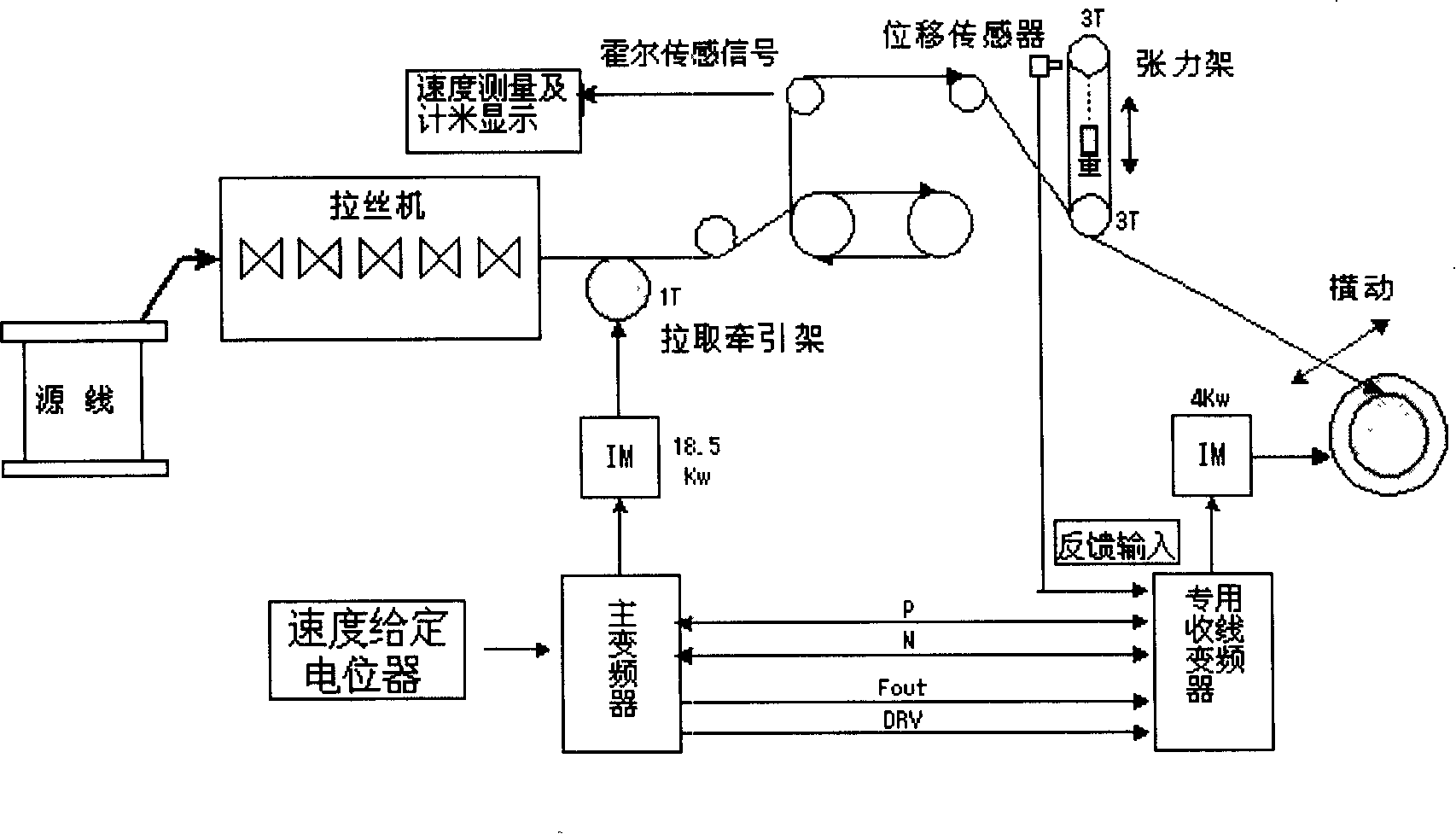

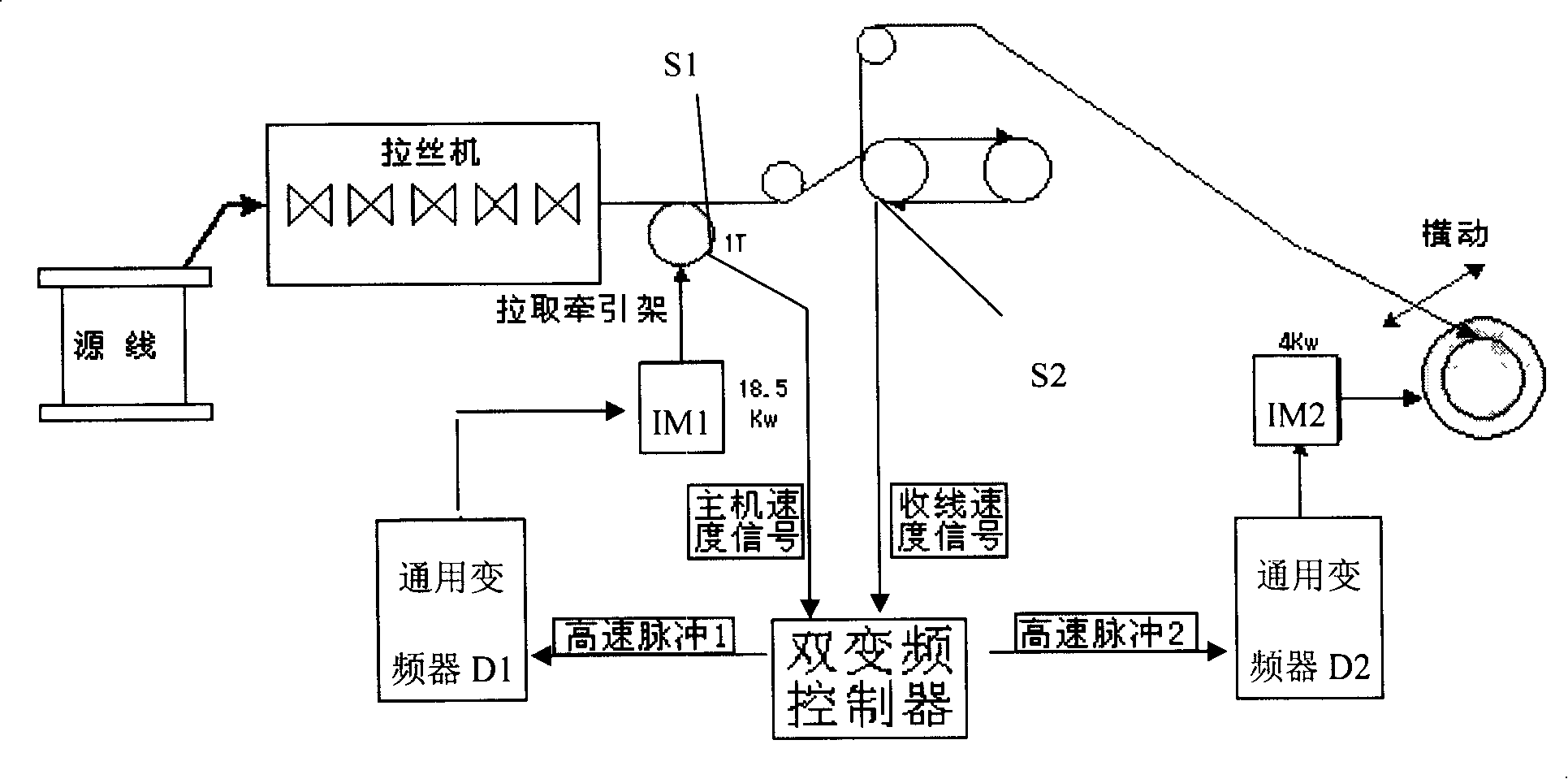

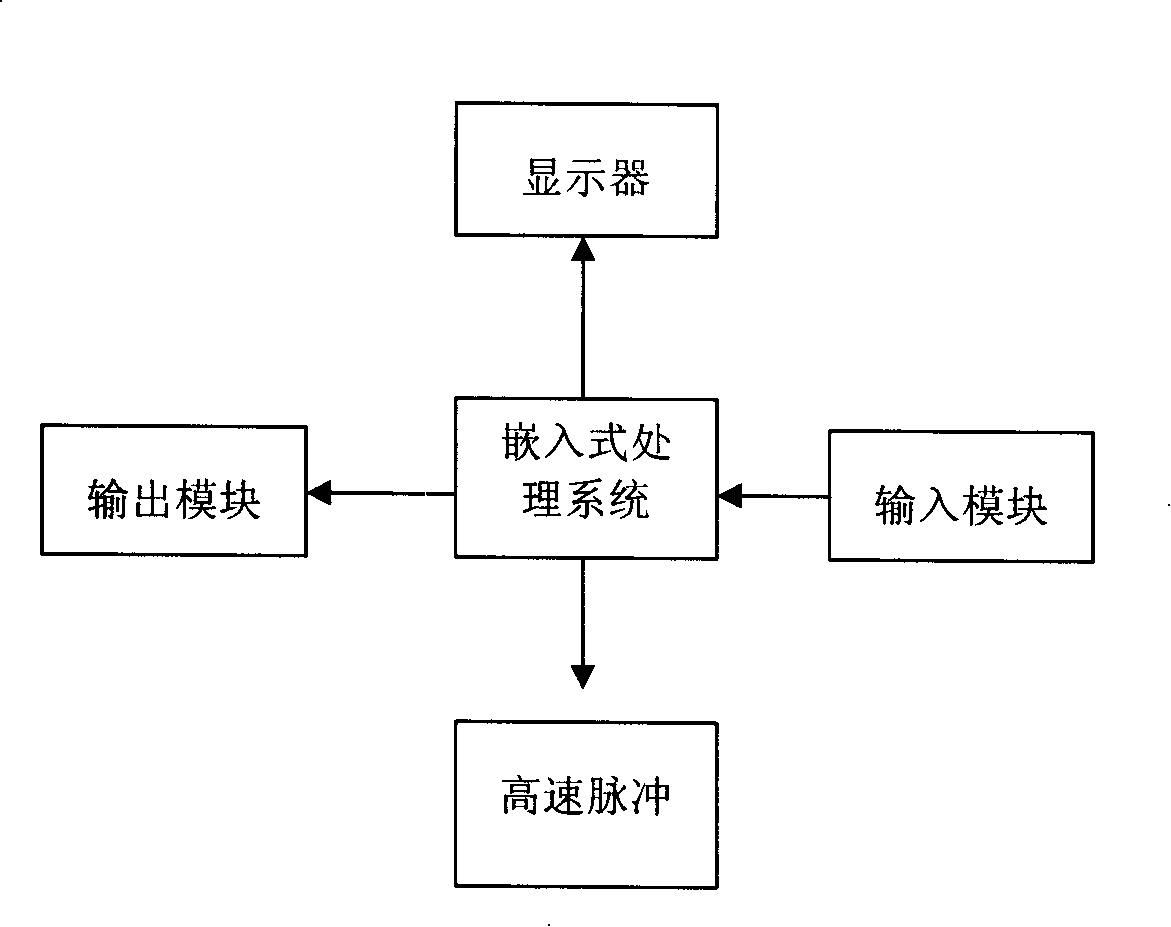

[0014] The invention provides a control system of a double frequency conversion type wire drawing machine, the schematic diagram of the working equipment of the wire drawing machine is attached figure 2 As shown, it includes main components such as a wire drawing machine, a first motor and a second motor, a frequency converter, a tower wheel, a sensor, and a pulling frame. The first motor controls the speed of driving the pulling frame, and the The second motor controls the speed of driving the take-up reel; it also includes a double frequency conversion controller, which respectively controls the first frequency converter D1 and the second frequency converter D2 through different high-speed pulses; the first frequency converter D1 and the first motor IM1 is electrically connected to control the speed of unwinding the wire from the wire drawing machine; the second frequency converter D2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com