Construction method of water-stopping combined continuous wall prefabricated by centrifugal process

A construction method and centrifugal technology, applied in water conservancy projects, artificial islands, sheet pile walls, etc., can solve the problems of poor quality and safety controllability, low safety factor, and long construction period, and achieve quality and safety controllability. Strong, high safety factor, good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

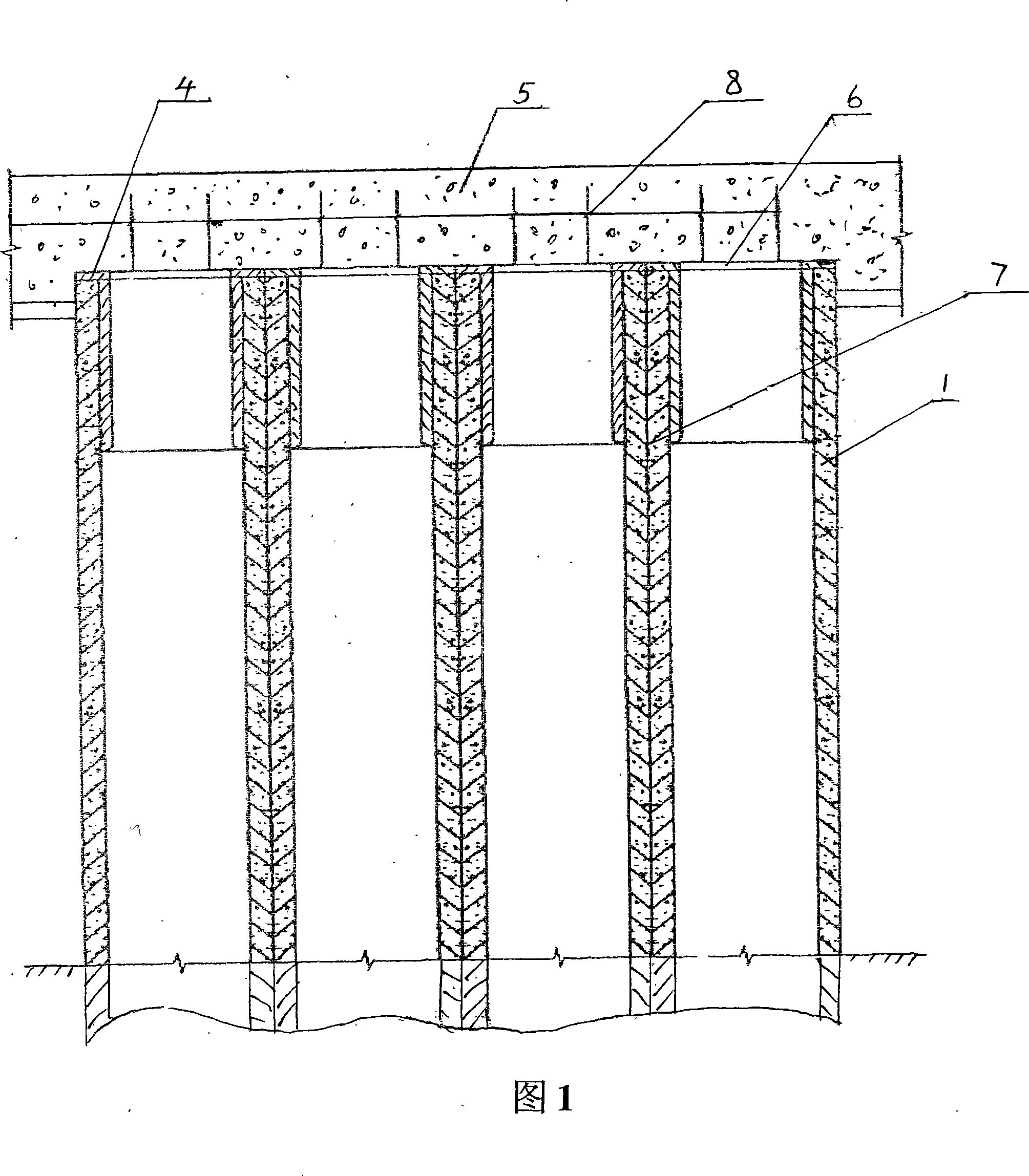

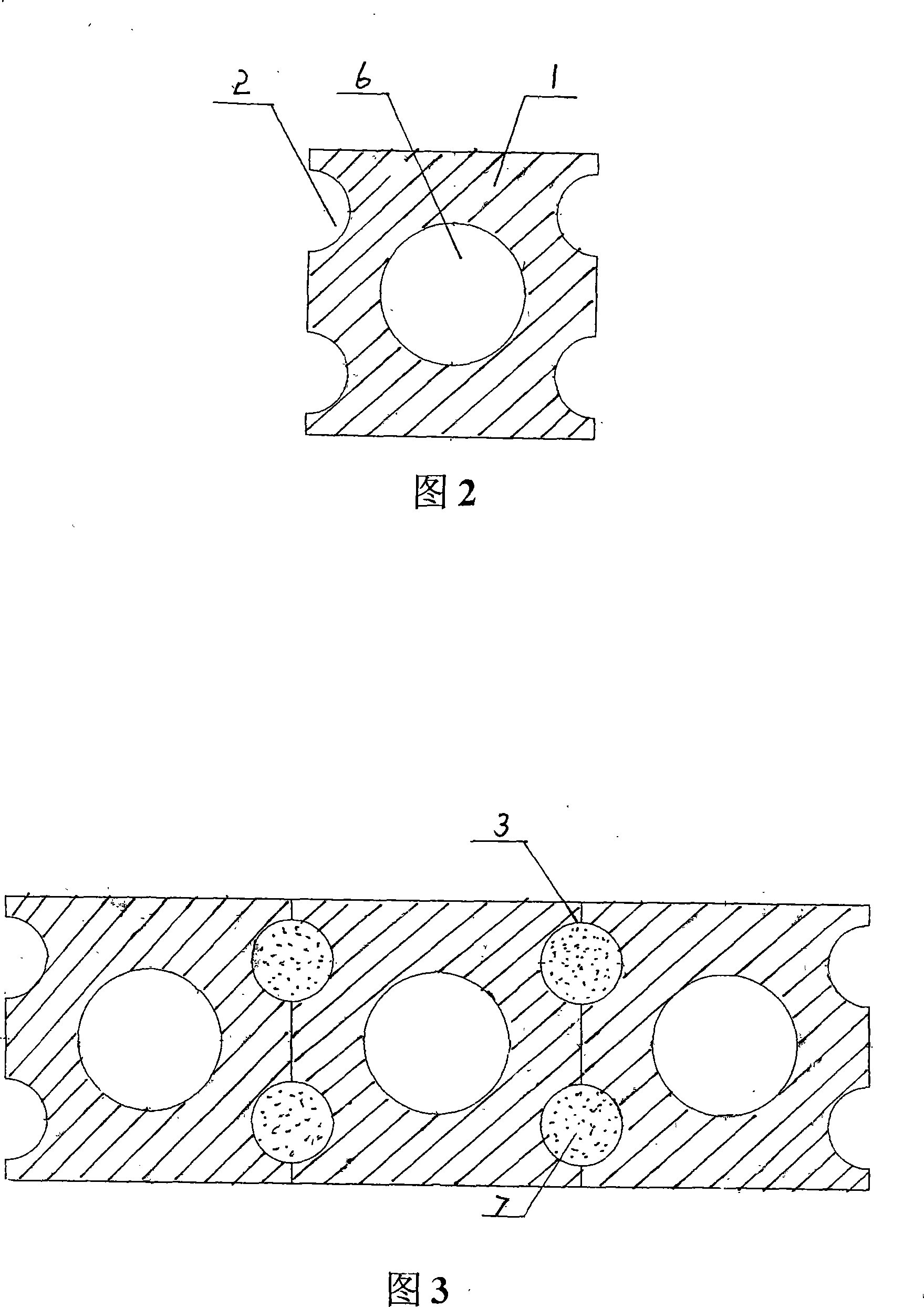

[0011] The water-stop composite continuous wall of the present invention is composed of several reinforced concrete members, concrete bodies 1, which are arranged adjacent to each other and the lower section is implanted underground. The number of water stop grooves 2 can be set to one or more; the water stop hole column 3 formed by the water stop grooves 2 of two adjacent concrete bodies 1 is filled with water stop material 7; the top of the concrete body 1 is provided with a connecting plate 4 And there is a reserved hole 6 on the top to insert the connecting steel bar 8; a cap beam 5 and the concrete body 1 are poured into one body through the connecting steel bar 8, the connecting plate 4 and the concrete, so that the cap beam connects the arranged concrete body 1 members into one integrated to form a complete continuous wall.

[0012] In the present invention, under the existing technical conditions, the concrete body 1 of the prefabricated water-stop composite continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com