Improved magnetic head tabs combination, magnetic disk drive and manufacturing method thereof

A disk drive and magnetic head technology, which is applied in the direction of aligning the magnetic track on the disk, driving/moving the recording head, supporting the head, etc., and can solve problems such as damage to the piezoelectric element, cracking or scratching of the surface area of the piezoelectric sheet, and damage to the piezoelectric sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

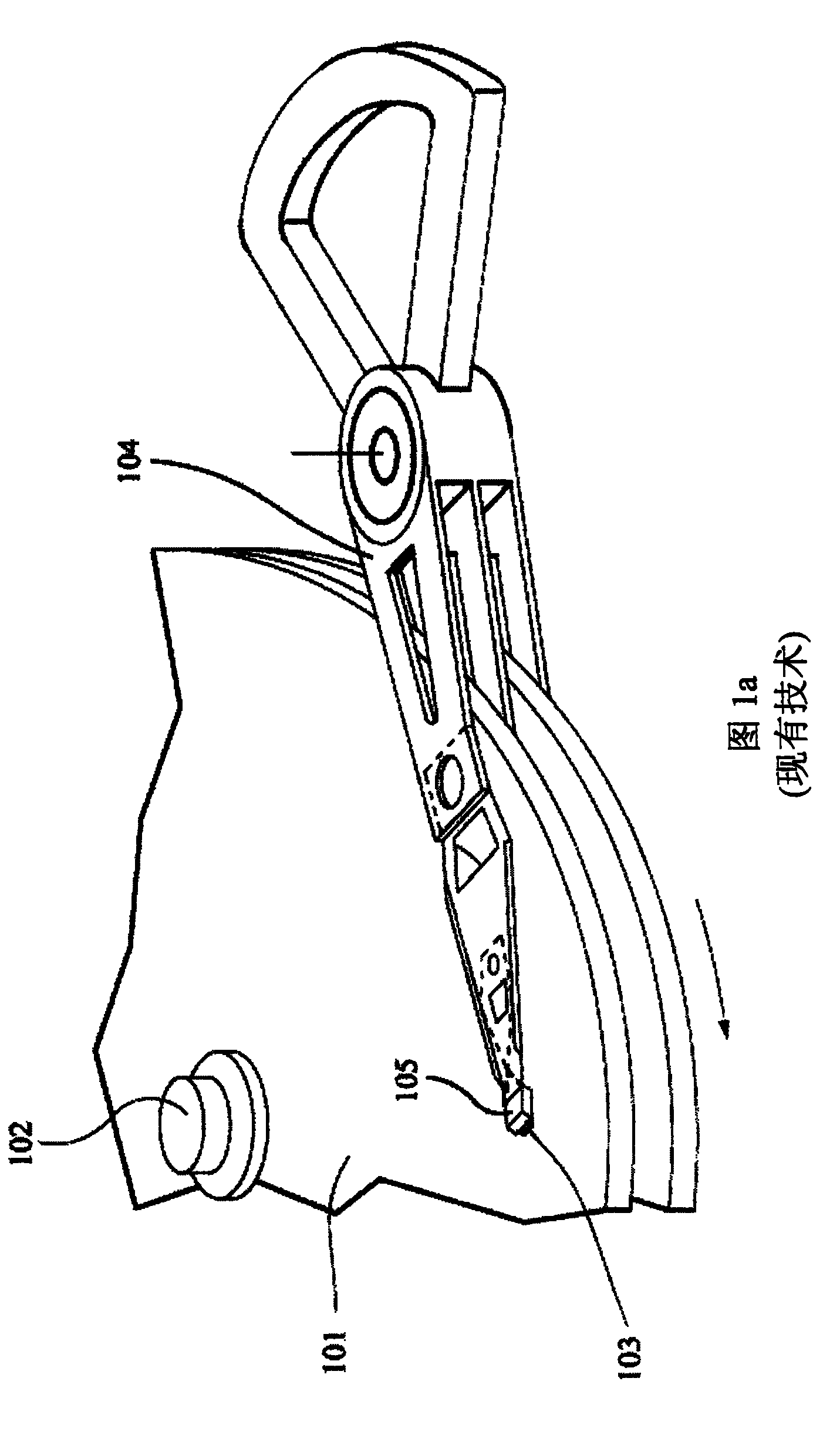

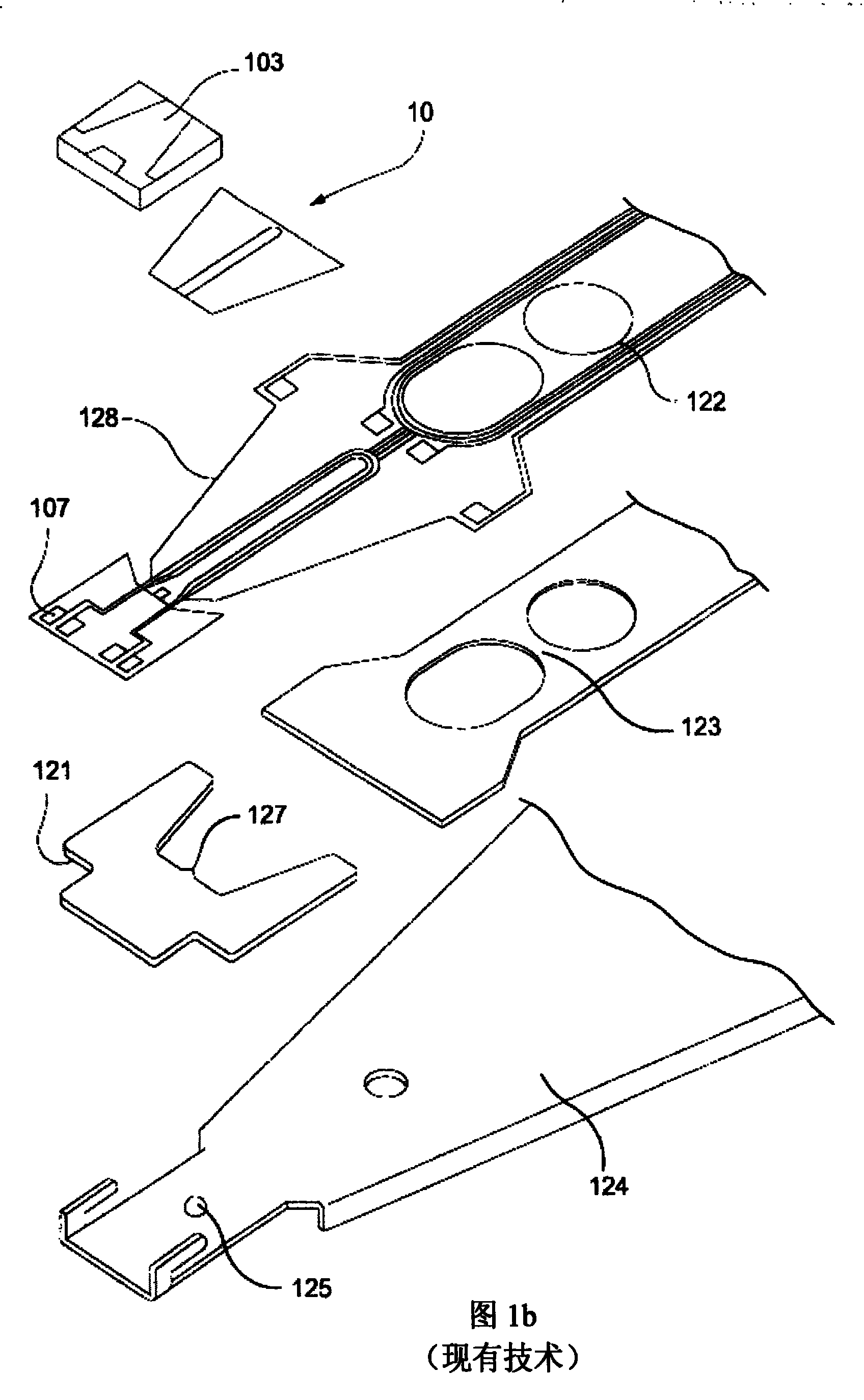

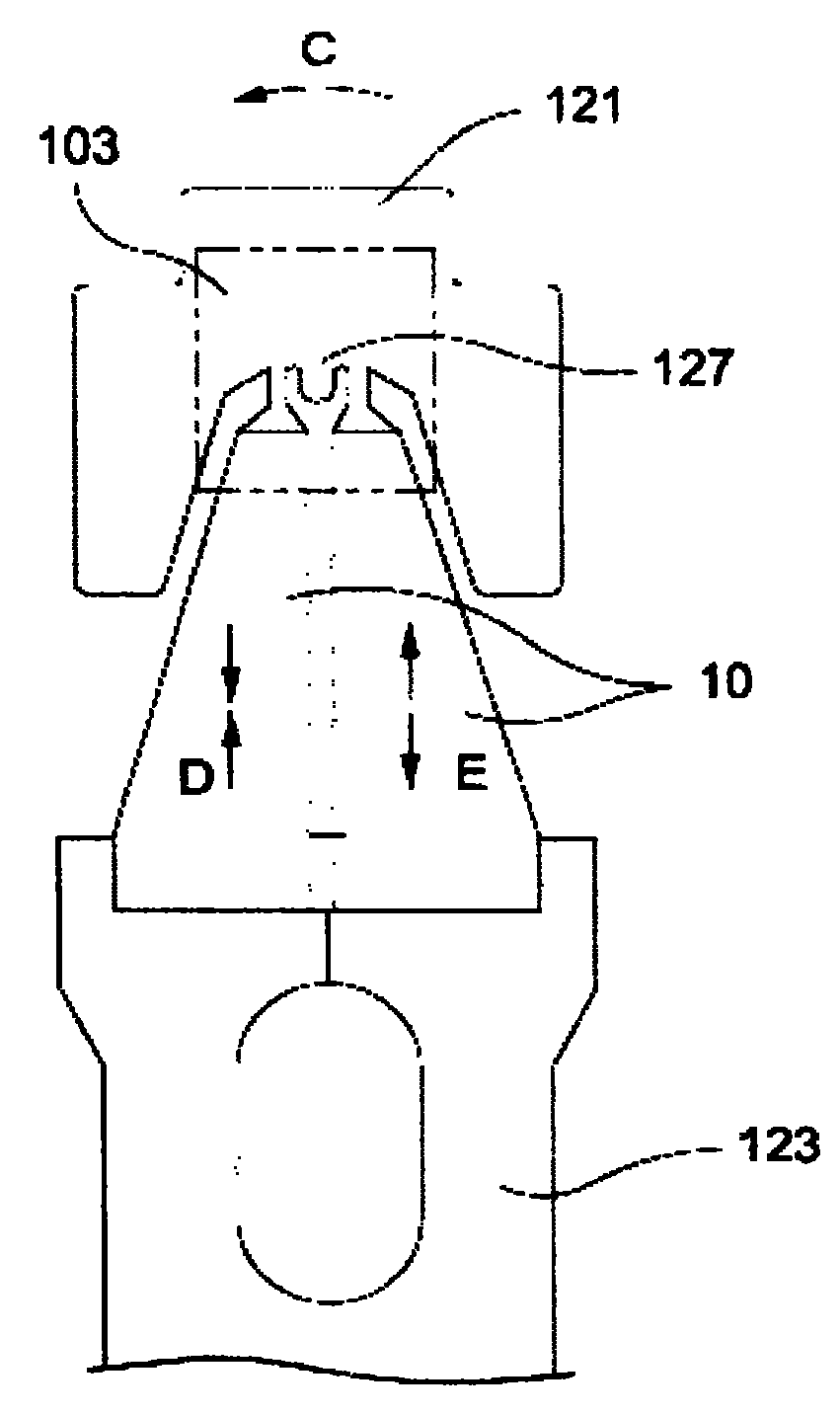

[0040] Conventional HGAs have a large cantilevered tongue area and thus require a parallel gap. However, such a structure easily damages the piezoelectric element, as described above. Therefore, the present invention aims to reduce the size of the tongue area, reduce or even eliminate the need for gaps, and ensure the performance of the HGA even when vibrations occur.

[0041] Embodiments of the present invention will now be described with reference to the drawings. FIG. 2 a is a perspective view of a HGA with a thin-film piezoelectric microactuator according to an embodiment of the present invention. The HGA 200 shown in FIG. 2 a includes a load bar 204 , a flexible member 209 , a pivot member 213 and a substrate 212 . The magnetic head 210 is partially installed on the top area of the tongue of the flexible member 209 and the bottom area of the tongue of the flexible member 209 . Two piezoelectric elements 202 are installed in the middle area of the flexible member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com