Dish type suspension insulator multi-station flow production cementing machine

A suspension insulator, multi-station technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of low production efficiency, manual cleaning, troublesome operation, etc., to reduce porosity and enhance the firmness of glue Degree, improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings.

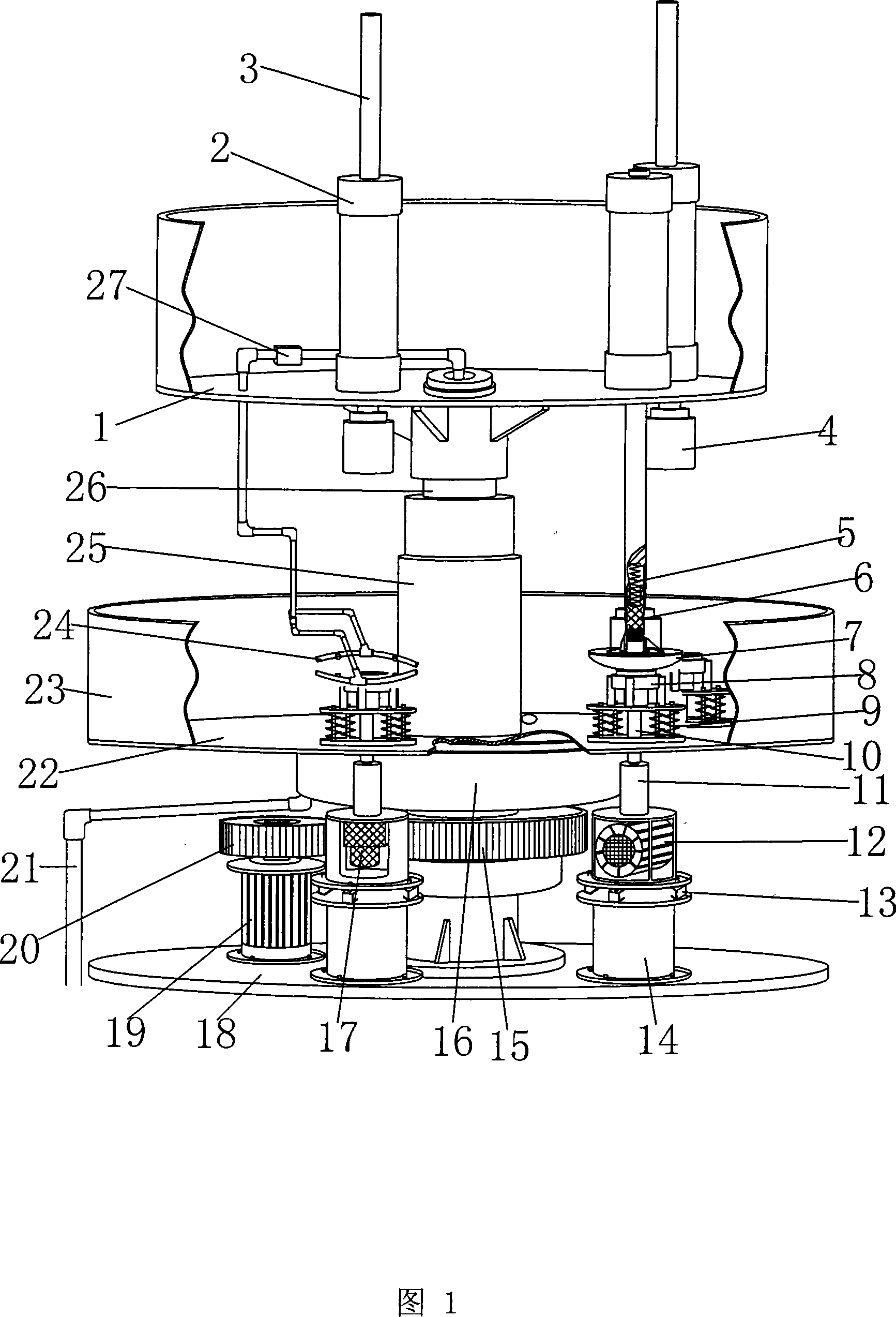

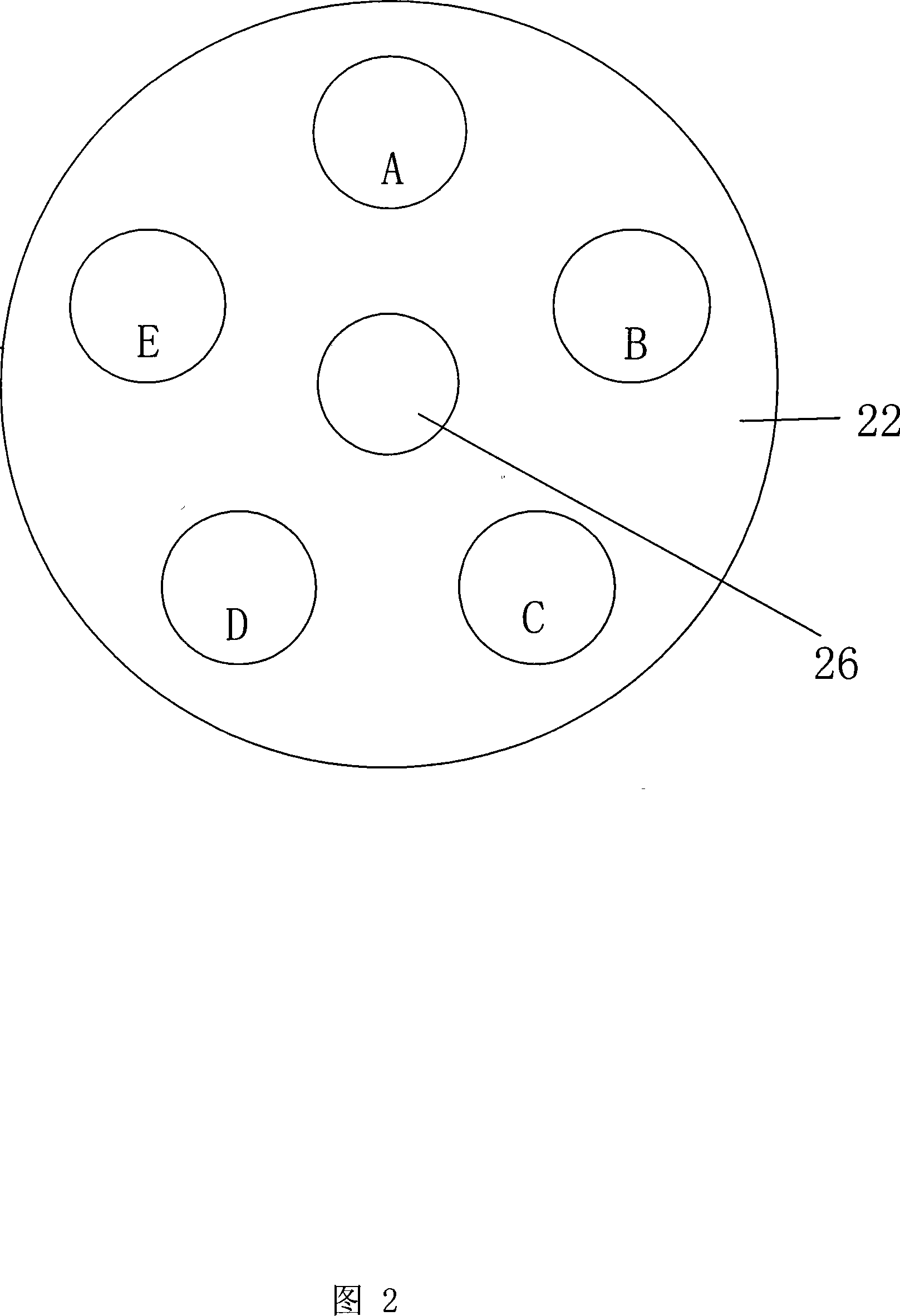

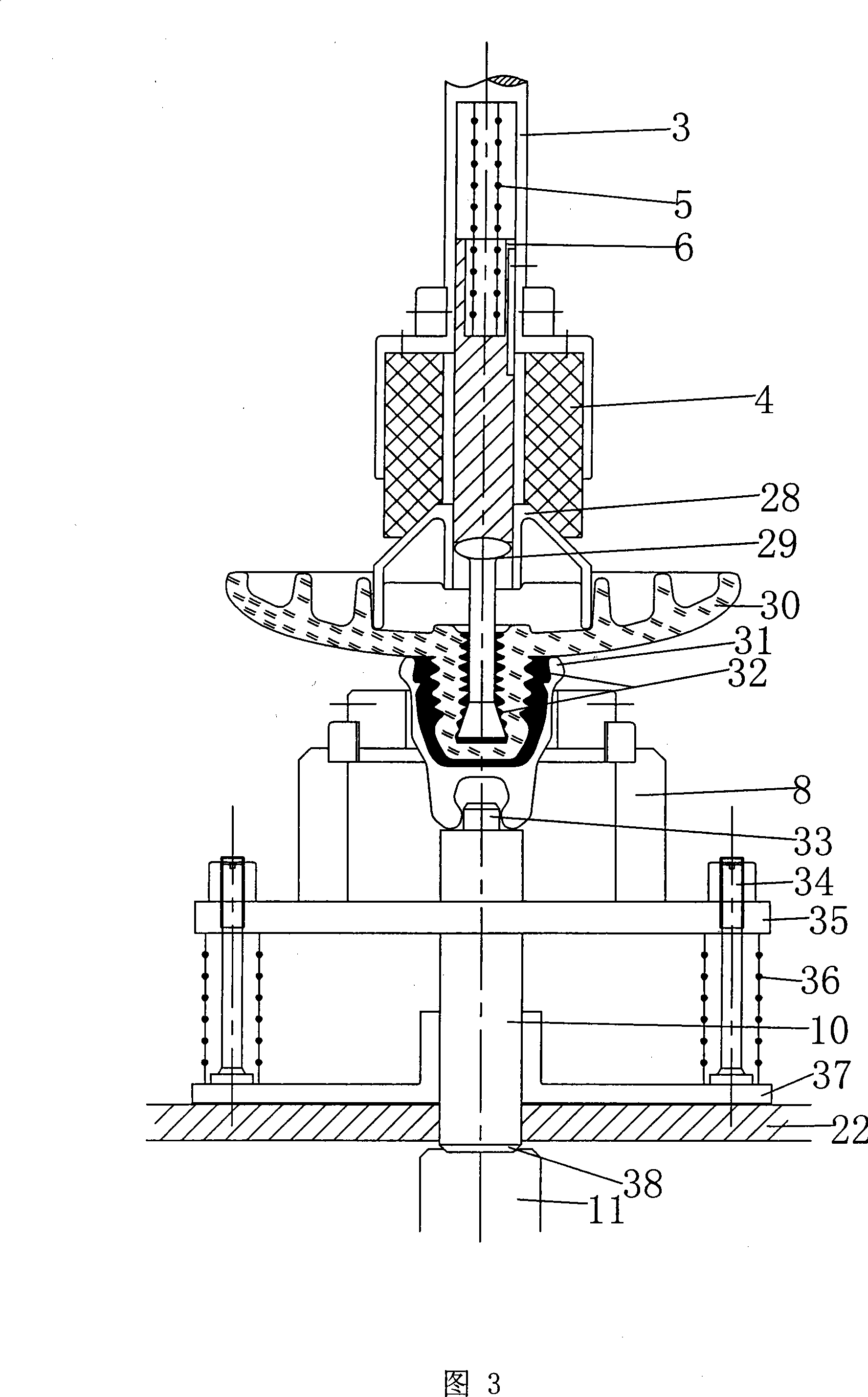

[0012] This embodiment is a disc-shaped suspension insulator five-station assembly line gluer. Its frame is composed of a base 18 and a central column 26. A disc-shaped worktable 22 is installed in the middle of the central column 26. The bottom of the disc-shaped workbench 22 passes through the The adjusting nut and bearing 16 are connected with the driven gear 15 installed on the central column 26, and the output shaft of the cam splitter 19 installed on the base 18 is provided with a driving gear 20 meshing with the driven gear 15; Five assembly line work stations A, B, C, D, E are arranged with mutual intervals of 72° on the shaped workbench 22, corresponding to the five stations, and five groups of glue with the same structure are installed on the disc-shaped workbench. The component support seat 8 and its elastic support 9, the elastic support 9 is composed of an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com