Permanent-magnet gyratory agitation device

A technology of rotating stirring and permanent magnets, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of uneven distribution of the magnetic field of the reaction tank, reduced magnetic force, and reduced rotational power, and achieves low shear force and speed regulation. Low power and the effect of promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained and illustrated below in conjunction with specific embodiments.

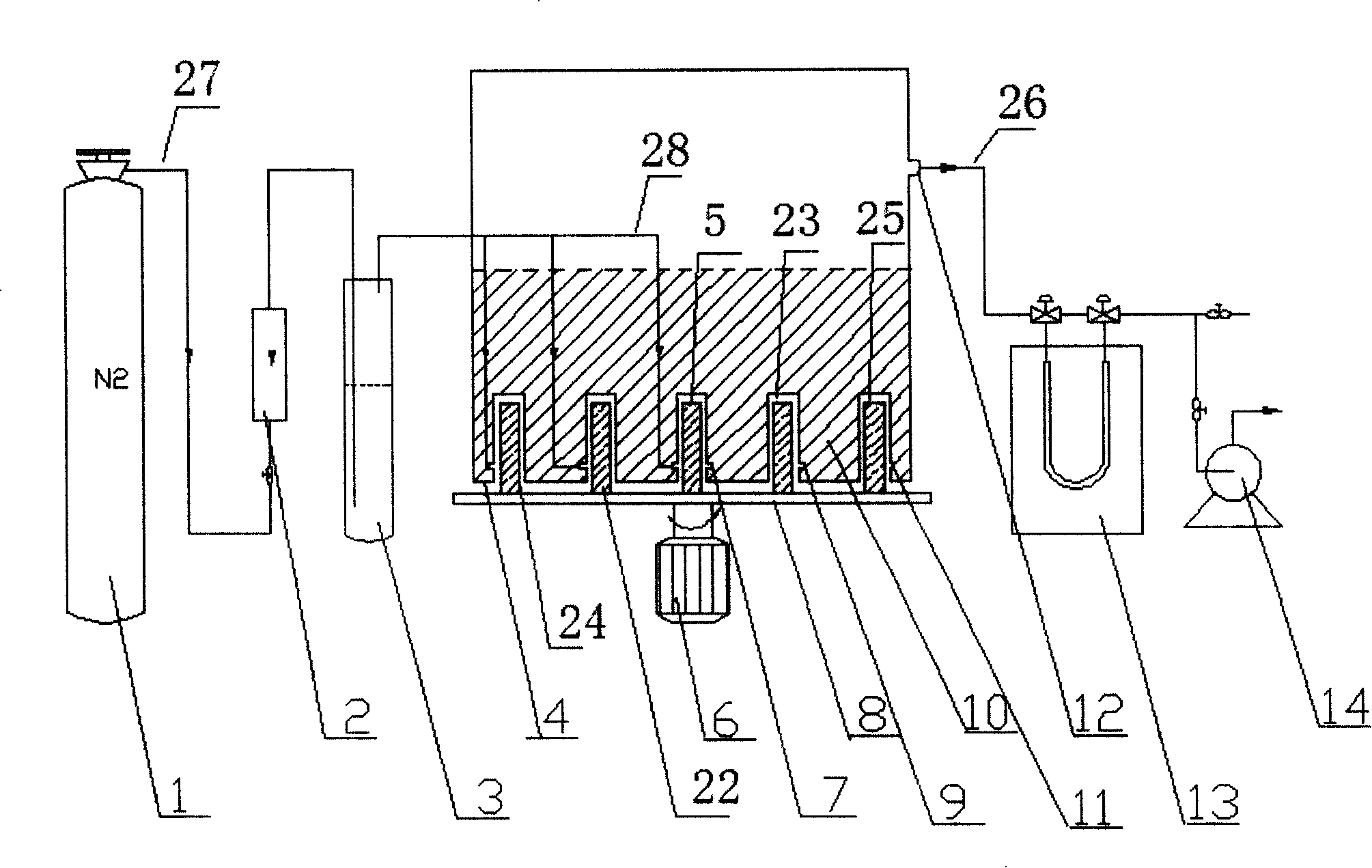

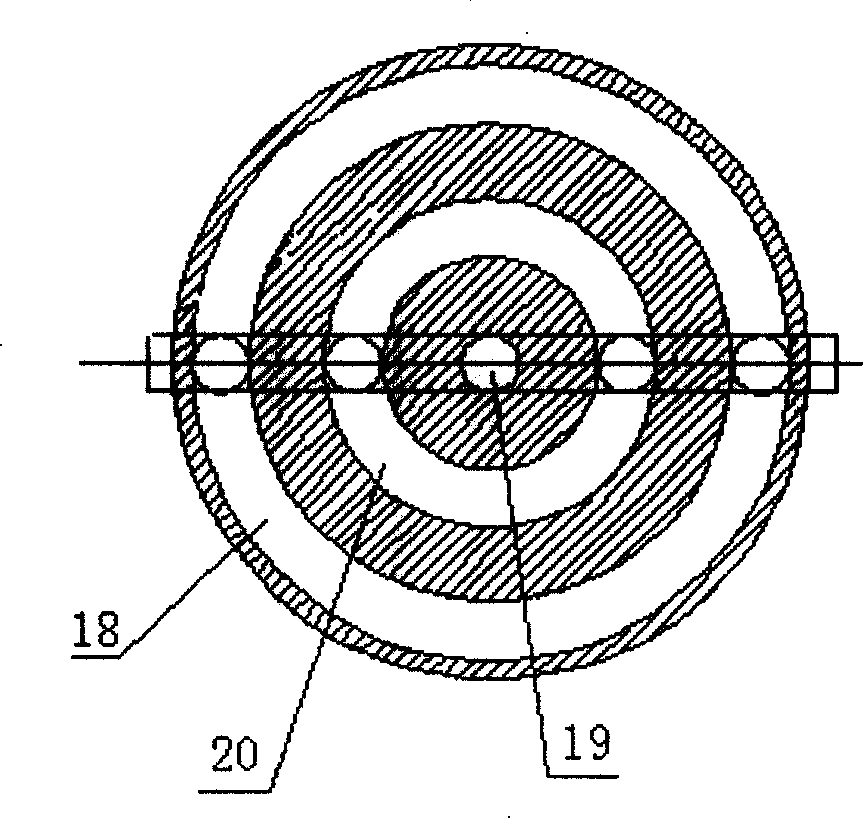

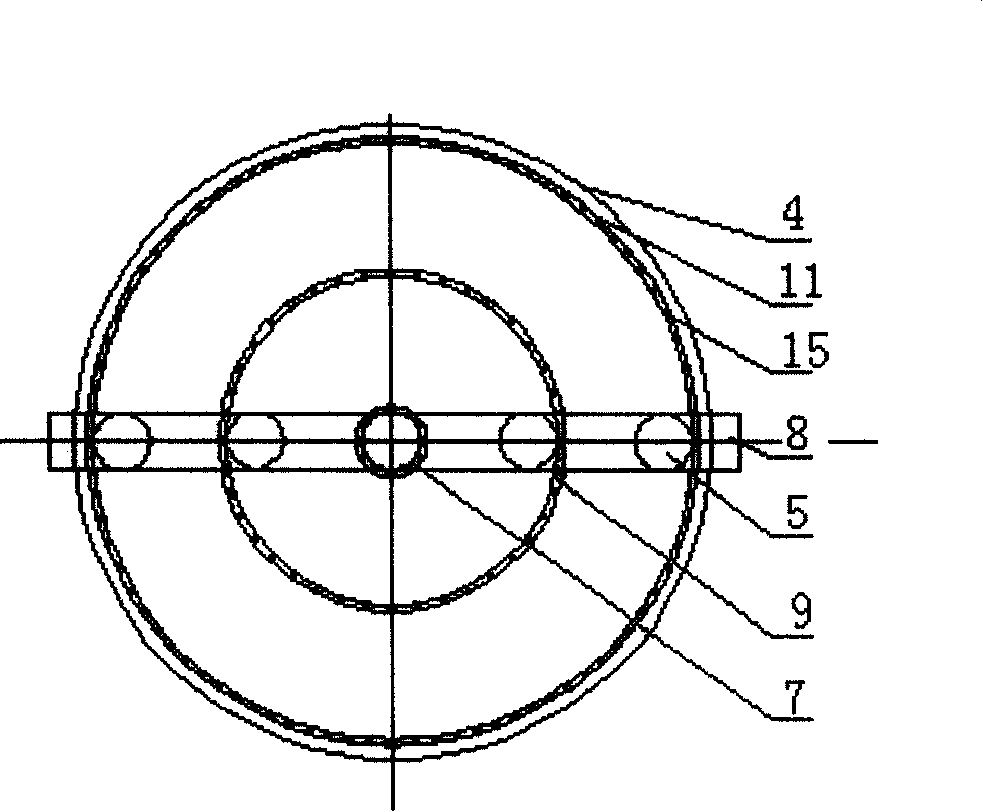

[0037] Such as figure 1 The shown system for measuring the absorption of benzene vapor by magnetic ionic liquid adopts the permanent magnet rotating stirring device of the present invention, and the nitrogen cylinder 1 is connected to the bottom of the solute storage tank 3 through the first gas path 27, and the first gas path is provided with The gas flow meter 2, the upper part of the solute storage tank 3 are respectively connected to the first, second and third annular gas distributors 7, 9, 11 through the second gas path 28, and the first, second and third annular gas distributors Devices 7, 9, 11 are fixed on the bottom of the cylindrical container 4 and placed concentrically, such as Figure 2b with Figure 2a As shown, except that there is a central magnet groove 19 for accommodating the first permanent magnet 5 at the bottom of the container 4, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com