Impact drill

An impact drill and drill bit technology, applied in the field of hand-held power tools, can solve the problems of operator difficulty, easy to cause fatigue, etc., and achieve the effects of convenient use, lightening burden, and reducing axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

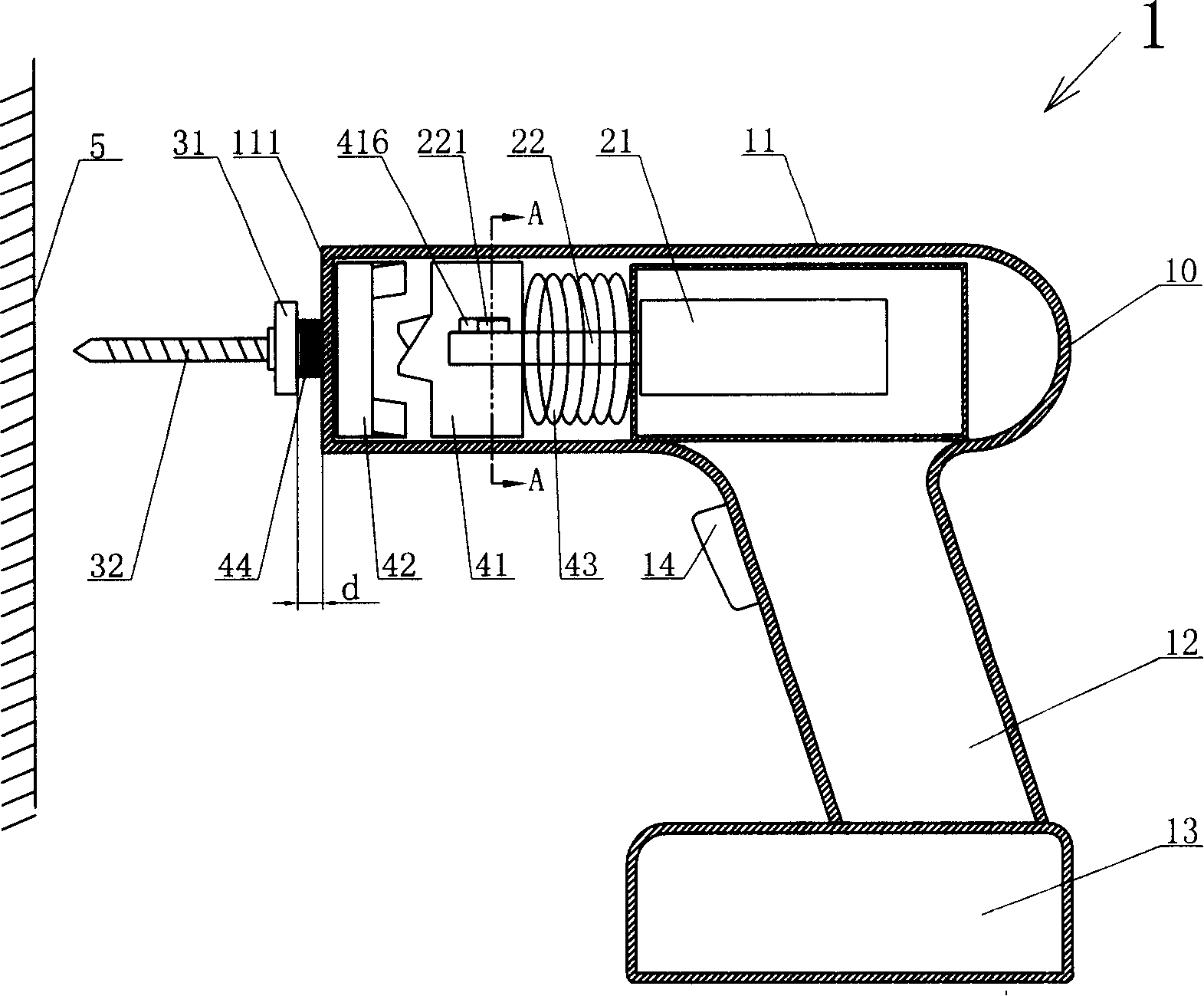

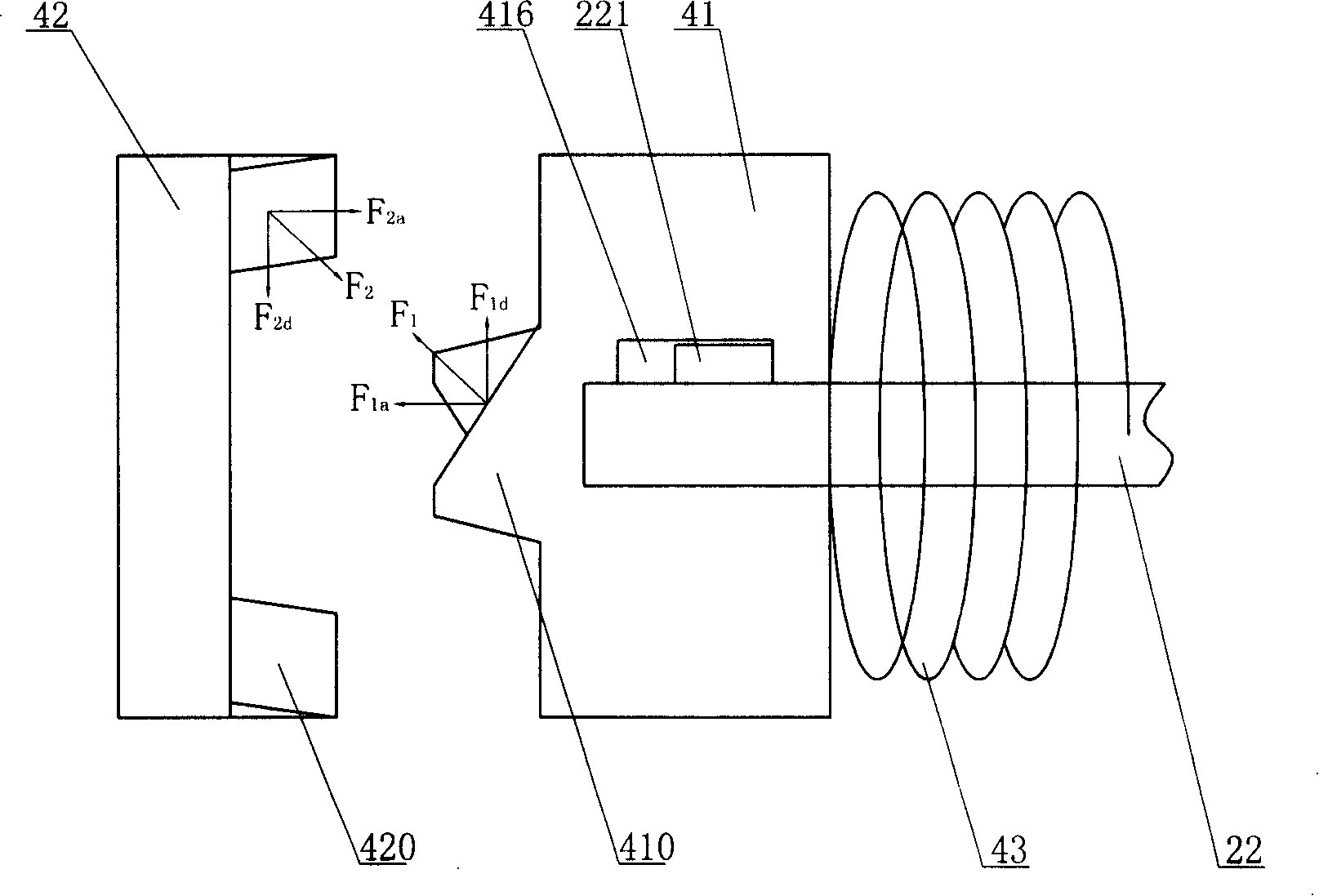

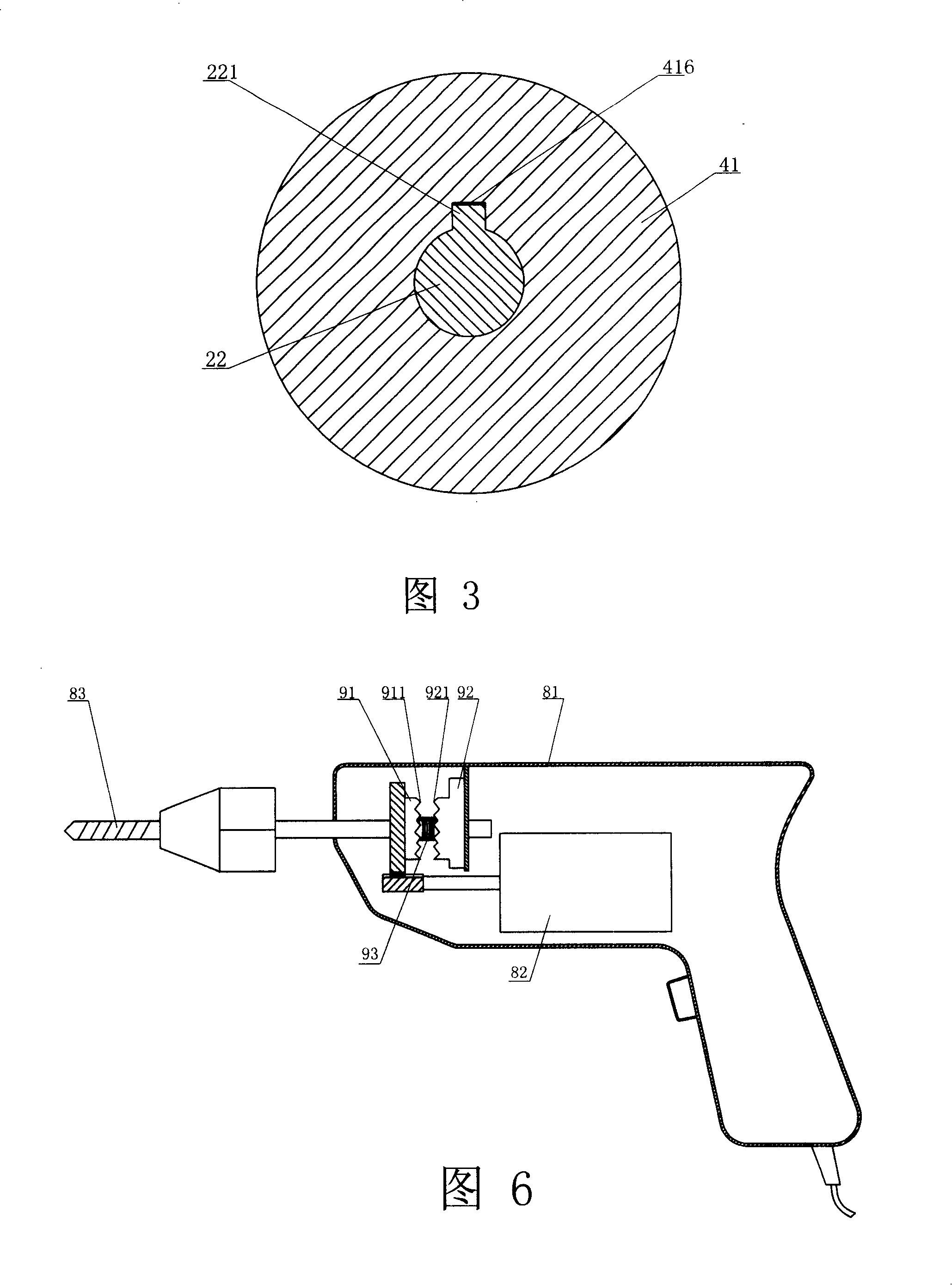

[0016] like figure 1 As shown, the present invention discloses a percussion drill 1 for drilling a hole on a workpiece 5, which includes a casing 10, a motor drive system arranged in the casing 10, a drilling system extending out of the casing, and The driving force generated by the motor drive system is transmitted to the transmission mechanism of the drilling system. The casing 10 has a horizontal cavity 11 extending horizontally, a handle 12 extending downward from the horizontal cavity approximately vertically, and a battery pack 13 located at the bottom of the handle 12 for providing power. A switch button 14 is provided on the handle 12 for controlling the opening and closing of the motor, and the operator can adjust the rotation speed of the motor by pressing the button deeply. The motor drive system is accommodated at the rear side of the horizontal cavity of the casing, and includes a motor body 21 fixedly disposed in the casing 10 and a motor shaft 22 horizontally e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com