Composition for manufacturing low-hardness rubber material

A technology of rubber materials and compositions, which is applied in the field of manufacturing low-hardness and high-damping rubber materials, can solve the problems of lack of elasticity and shape stability, high price, loss of practicability, etc., and achieve the effect of eliminating small high-frequency vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1~3

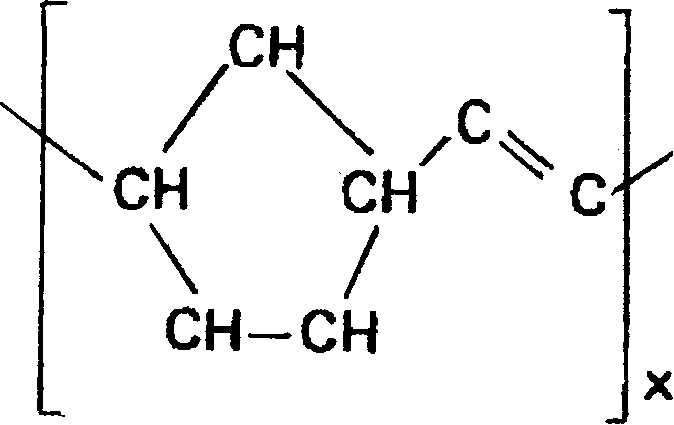

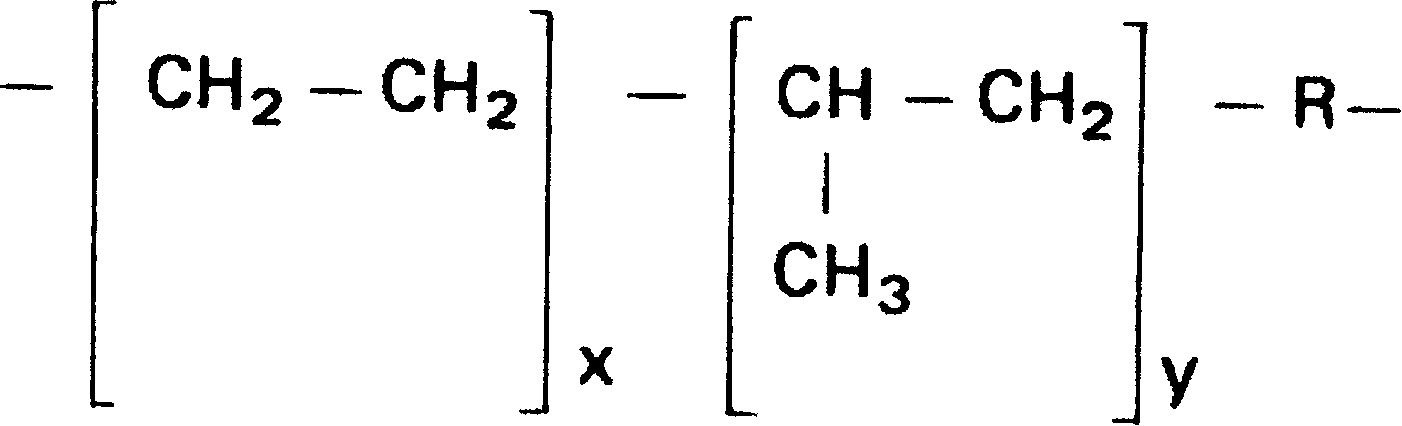

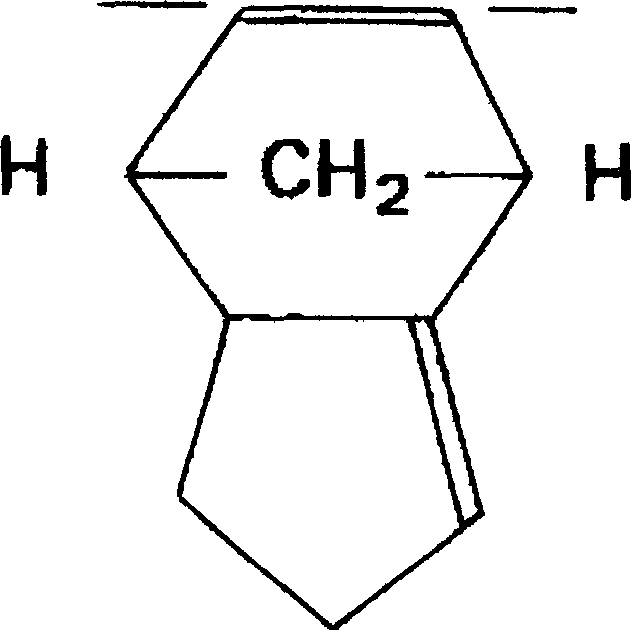

[0030] According to the formula listed in Table 1, 330 parts of naphthenic oil and 1.5 parts of vulcanizing agent dimorpholine disulfide are respectively added to masterbatch A and masterbatch B, and the two kinds of masterbatches are used in different proportions. The third monomers of EPDM rubber are 5-ethylidene-2-norbornene (ENB) and dicyclopentadiene (DCPD), the dosage is listed in Table 2, and the test was made by vulcanization at 160°C×30min Using standard test pieces, the test results obtained are shown in Table 2.

[0031] Table 2

[0032]

[0033]

Embodiment 2

[0034] Embodiment 2 and Comparative Examples 4-6

[0035] Embodiment 2 is to change 330 parts of naphthenic oils and 1.5 parts of vulcanizing agent dimorpholine disulfide in embodiment 1 into 310 parts of naphthenic oils and 2 parts of vulcanizing agent dimorpholine disulfides. Comparative example 4 is to change the vulcanizing agent dimorpholine disulfide in embodiment 1 into 1.5 parts of sulfur. In Comparative Example 5, the EPDM rubber in Example 1 was changed to a variety with a propylene content of 45% by mass. 310 parts of naphthenic oil and 1.5 parts of vulcanizing agent dimorpholine disulfide were added to the masterbatch A to make comparative example 6. The test results are shown in Table 3.

[0036] table 3

[0037]

[0038]

[0039] From the test results shown in Table 2 and Table 3, it can be seen that the composition of the present invention can be used to prepare low-hardness rubber materials with Shore A hardness ≤ 10 and excellent comprehensive physica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com