Method for gluing conveyer belt joint

A conveying belt and gluing technology, applied in belt fasteners, belts/chains/gears, mechanical equipment, etc., can solve the problems of influence, long production time, long time, etc., to increase the roughening process and prolong the use. The effect of longevity, tool simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The bonding length at both ends is taken as 0.9-1.5 times the width of the conveyor belt. Take a conveyor belt with a width of 650mm as an example to illustrate the bonding method. The conveyor belt has five layers of canvas.

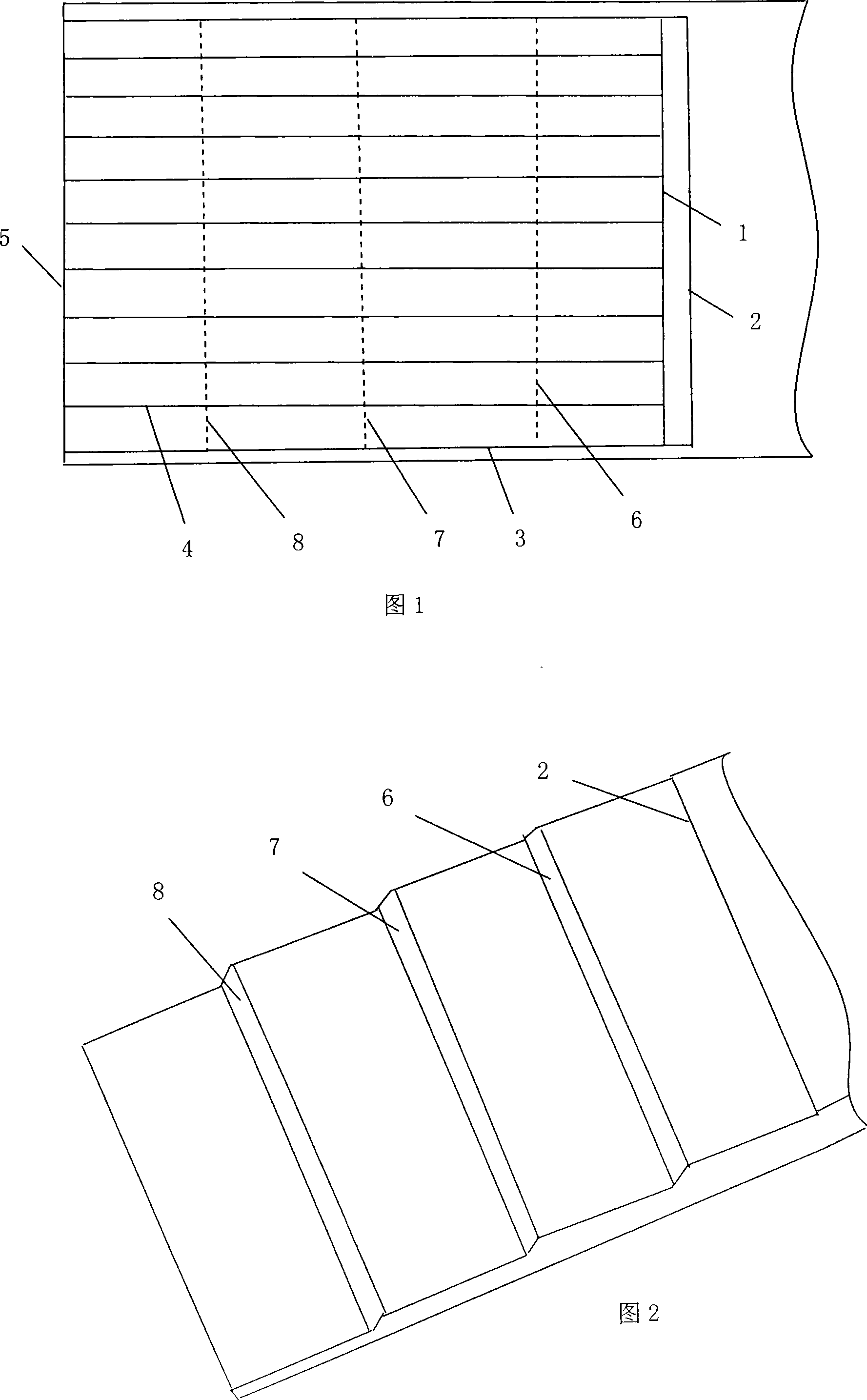

[0020] (1) draw a line, as shown in Figure 1

[0021] First, draw two inner horizontal lines 2 and outer horizontal lines 1 with a distance of 8-10mm parallel to the end surface at a distance of about 600mm from the end surface 5 of the conveyor belt. Draw a border line 3 between the lines 2, and draw a vertical line 4 between the end face 5 and the outer horizontal line 1 every 50 mm from the border line. The purpose of drawing the border line is because the rubber layer, not the canvas layer, is between the side of the conveyor belt and the border line.

[0022] (2) cutting and stripping, as shown in Figure 2

[0023] a Cut off the first layer of canvas along the inner horizontal line 2, outer horizontal line 1 and two border lines 3, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com