Method and device for monitoring plasma generator cathode life

A plasma and monitoring device technology, applied in the field of cathode life monitoring of plasma generators, can solve problems such as unit loss, and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

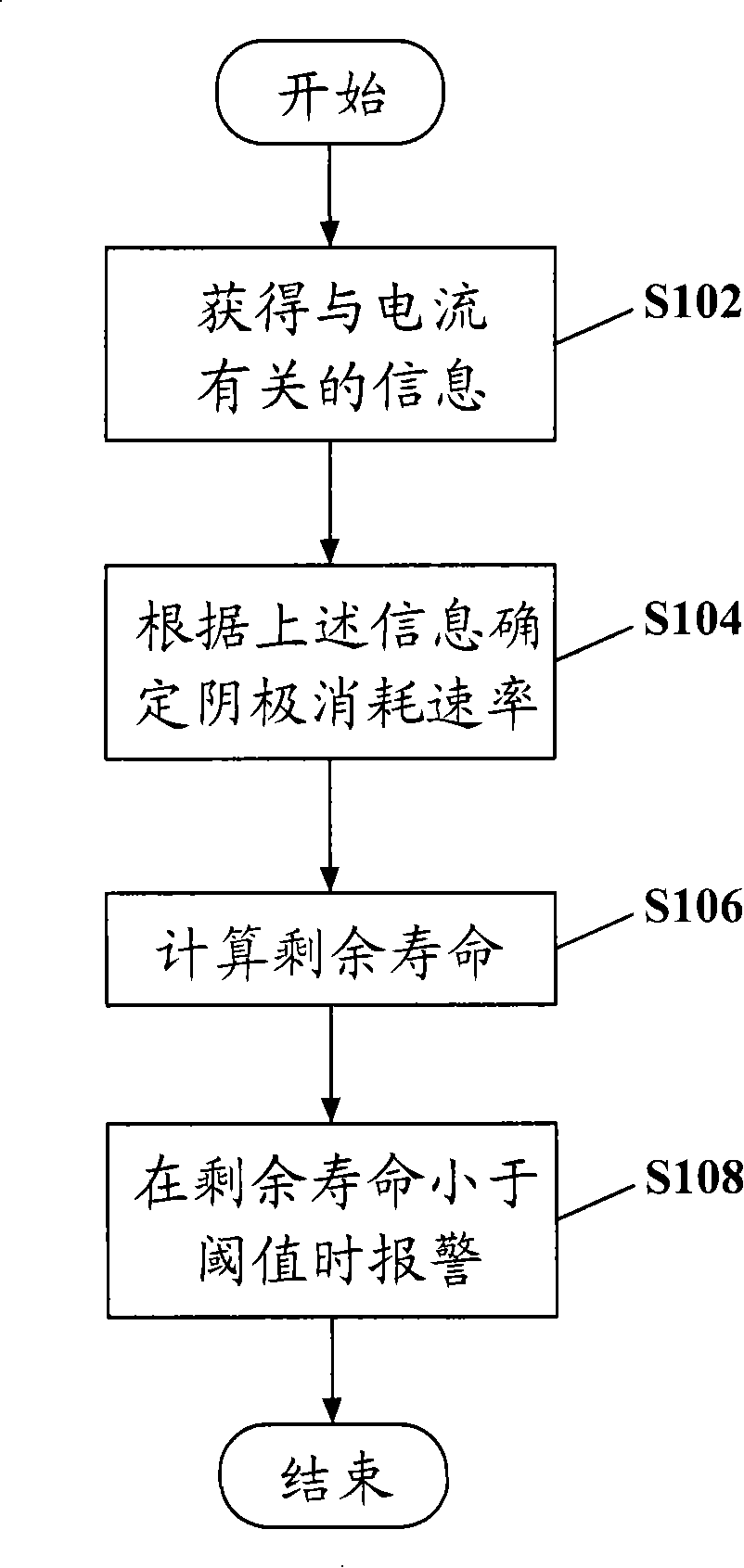

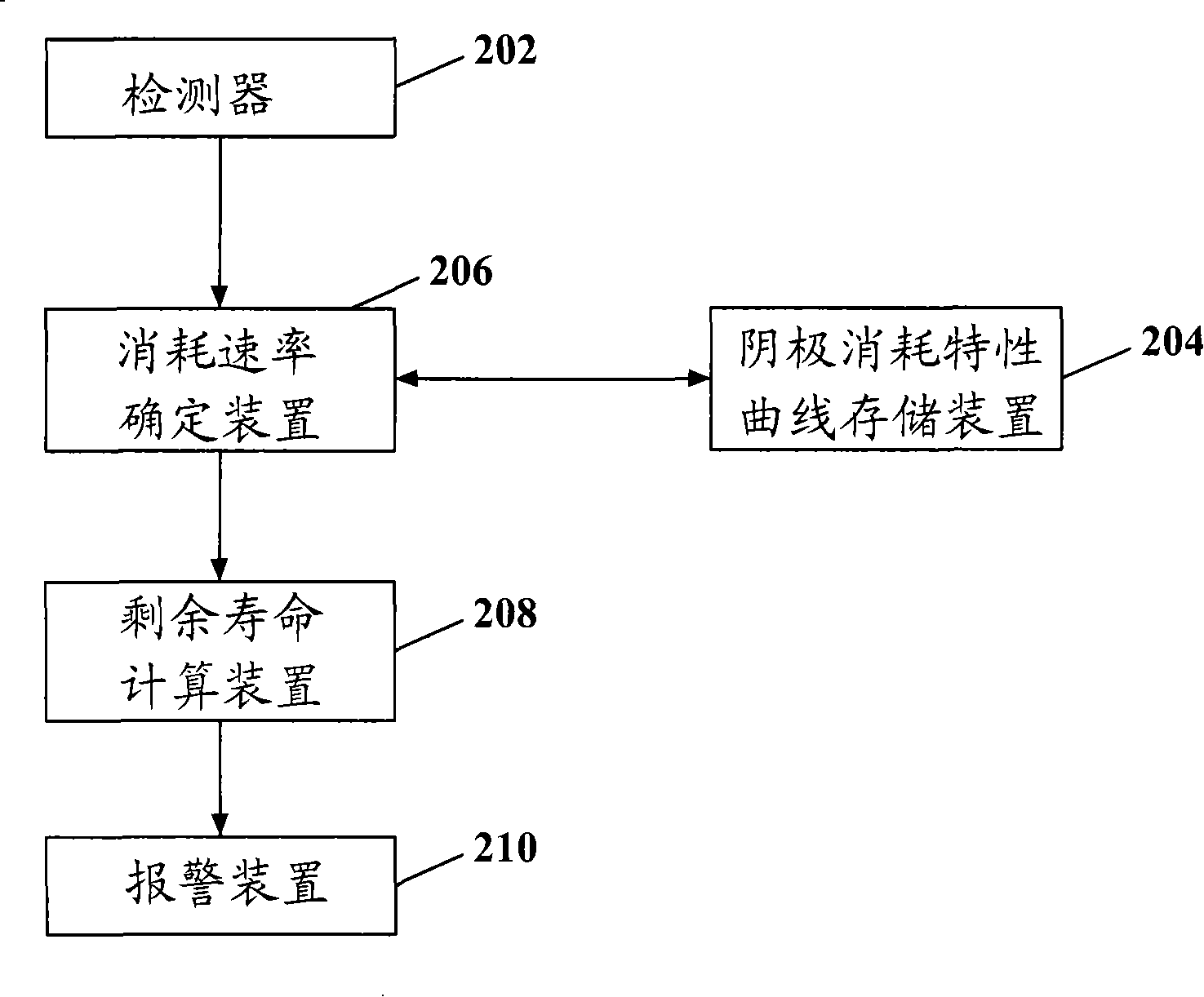

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The basic working principle of the plasma ignition device is electrode contact arc ignition, that is, after the cathode contacts the anode, a specific DC power supply is used to increase the current to the cathode and anode, and when the cathode leaves the anode, the arc is ignited, and at the same time, the arc is ignited by the magnetic force of the coil. Pulled out of the nozzle, the compressed air is ionized into high-temperature plasma under the action of the arc, forming a plasma arc. The plasma arc ignites the boiler soot.

[0018] According to the working principle of the plasma arc, the cathode is the high-temperature part of the plasma generator that emits electrons, and the burning loss is the working characteristic of the electrode. There are many factors that affect the service life of the cathode, among which the main fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com