Device for adsorbing, desorbing and purifying organic gas

A purification device and organic gas technology, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as low work efficiency, inability to directly discharge into the atmosphere, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

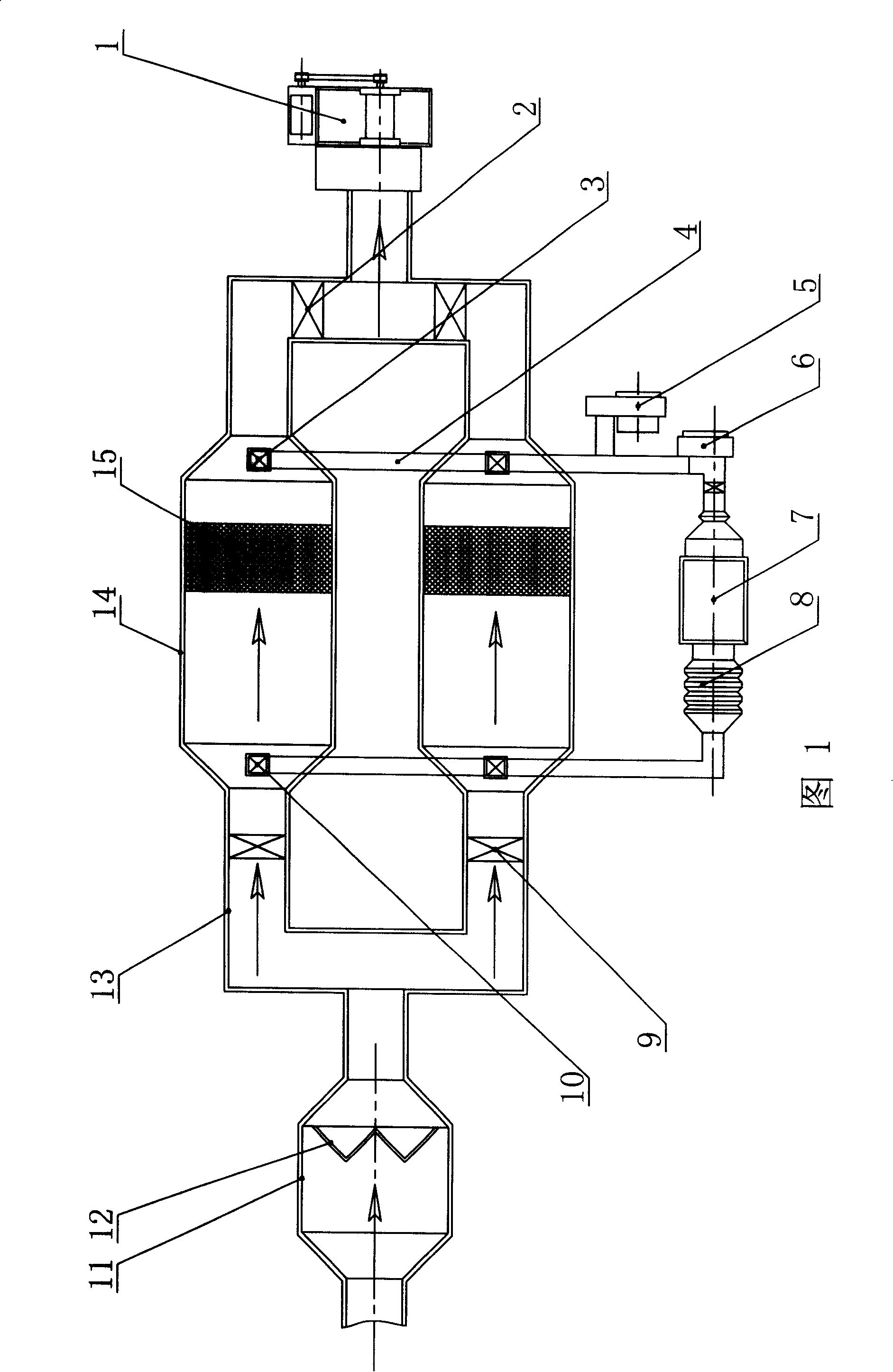

[0008] As shown in the figure, the organic gas adsorption, desorption, and purification device includes a filter device 11. A filter screen 12 is provided in the filter device 11 to filter dust. Adsorption device, the outlet of the adsorption device is connected to the atmosphere through the exhaust fan 1, the adsorption device includes two adsorption towers 14 arranged in parallel, the inlet and outlet of the adsorption tower 14 are respectively provided with an inlet valve 9 and an outlet valve 2, and the adsorption tower 14 is provided with Activated carbon adsorption filter material 15, a circulating air outlet 10 is provided behind the inlet valve 9, a circulating air inlet 3 is provided in front of the outlet valve 2, a stop valve is provided on the corresponding pipelines of the circulating air outlet 10 and the circulating air inlet 3, and the circulating air outlet 10 and the circulating air inlet 3 are connected with a flame arrester 8, an exhaust gas burner 7 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com