Half-thermosetting anisotropic conductive film composition

An anisotropic and thermosetting technology, applied in the field of anisotropic conductive film composition, can solve the problems of reduced reliability, difficult control of thermoplastic resin shrinkage and expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: 80 g of carboxylated acrylonitrile butadiene copolymer (1072CGX, Zeon Chemicals, weight average molecular weight=204,400) was dissolved in a mixed solvent of toluene / methyl ethyl ketone (2 / 1, weight ratio) to reach 24% solids content.

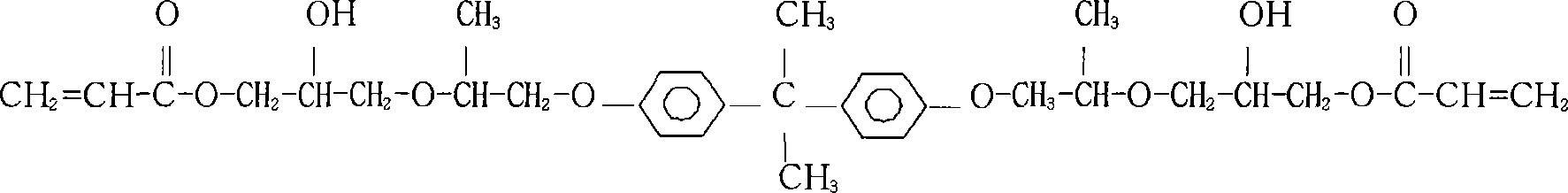

[0049] Then add 75 g of bisphenol A type epoxy acrylate resin (VR60, Showa Highpolymer Co.LTD. weight average molecular weight = 7,500) dissolved in methyl ethyl ketone to a solid content of 60%, and add 45 g of 2,500 weight average molecular weight Acrylate resin [the following formula (1)].

[0050] 13g and 4g of pentaerythritol triacrylate (weight-average molecular weight=298) and 2-acryloyloxyethyl phosphate (weight-average molecular weight=196) with three acrylate functional groups were added respectively, and 4g of Benzoyl peroxide was added to a solids content of 10%.

[0051] 1.7 g of a silane coupling agent having a methacryloxy group (3-glycidoxypropyltriethoxysilane) and 19 g of nickel (Ni) particles were added to...

Embodiment 2

[0054] Example 2: An ACF composition was prepared according to the method of Example 1 except that 80 g of carboxylated acrylonitrile butadiene dissolved in a mixed solvent of toluene / methyl ethyl ketone (2 / 1 by weight) to a solids content of 25% was used Carboxylated acrylonitrile butadiene copolymer (N34, Zeon Chemicals, weight average molecular weight = 236,400) was substituted for carboxylated acrylonitrile butadiene copolymer (1072CGX, Zeon Chemicals, weight average molecular weight = 204,400).

Embodiment 3

[0055] Example 3: An ACF composition was prepared according to the method of Example 1, except that 80 g of acryl rubber (SG-80H, Nagase Chemtex, weight average molecular weight=350,000) dissolved in methyl ethyl ketone to a solid content of 26% was used instead Carboxylated acrylonitrile butadiene copolymer (1072CGX, Zeon Chemicals, weight average molecular weight = 204,400).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com