Liquid-cooled direct driving motor stator

A motor stator, direct-drive technology, applied in the magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of material consumption and cost, heat conduction obstacles, incomplete abutment gap, etc., to achieve the structure Simple, heat-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

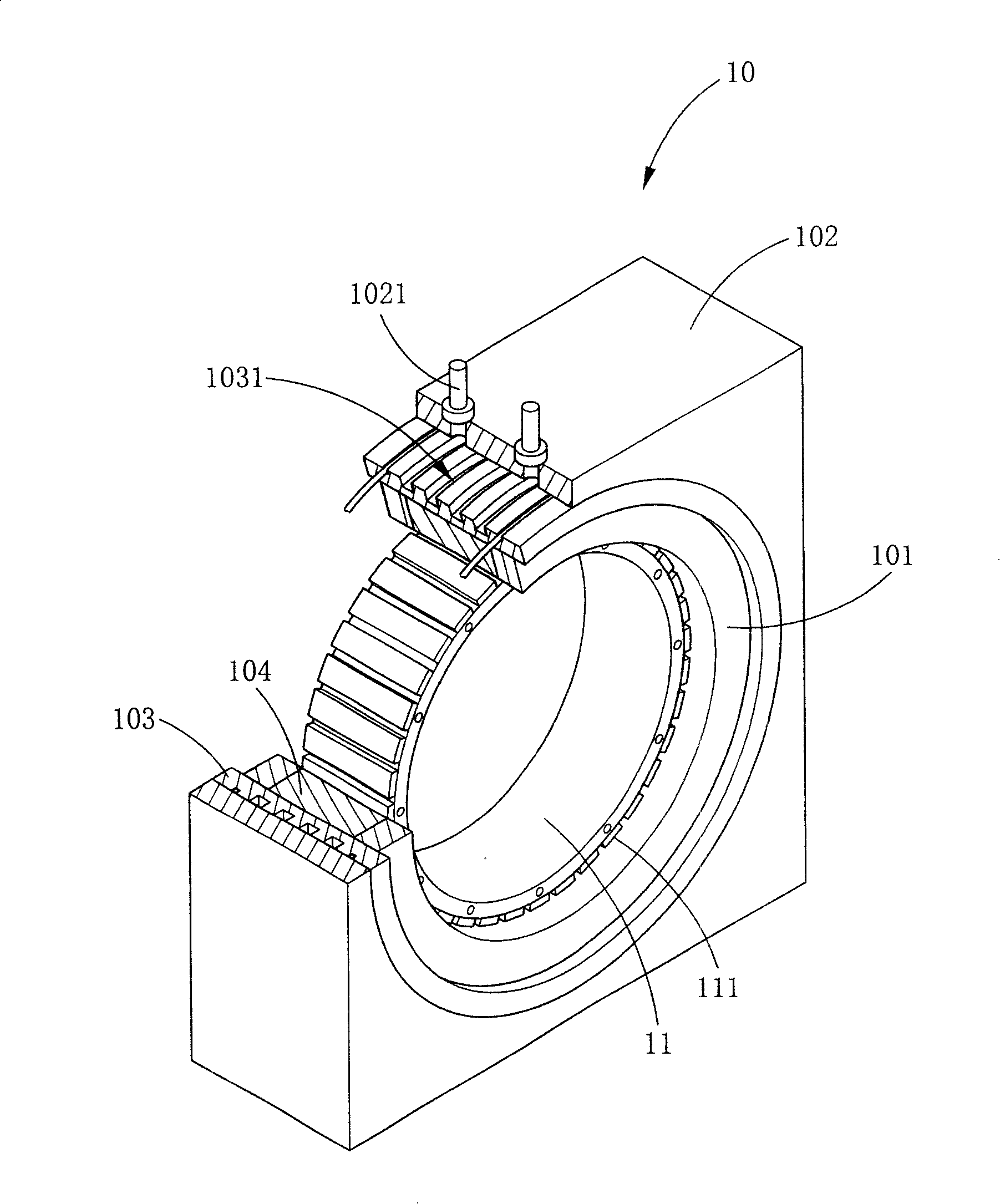

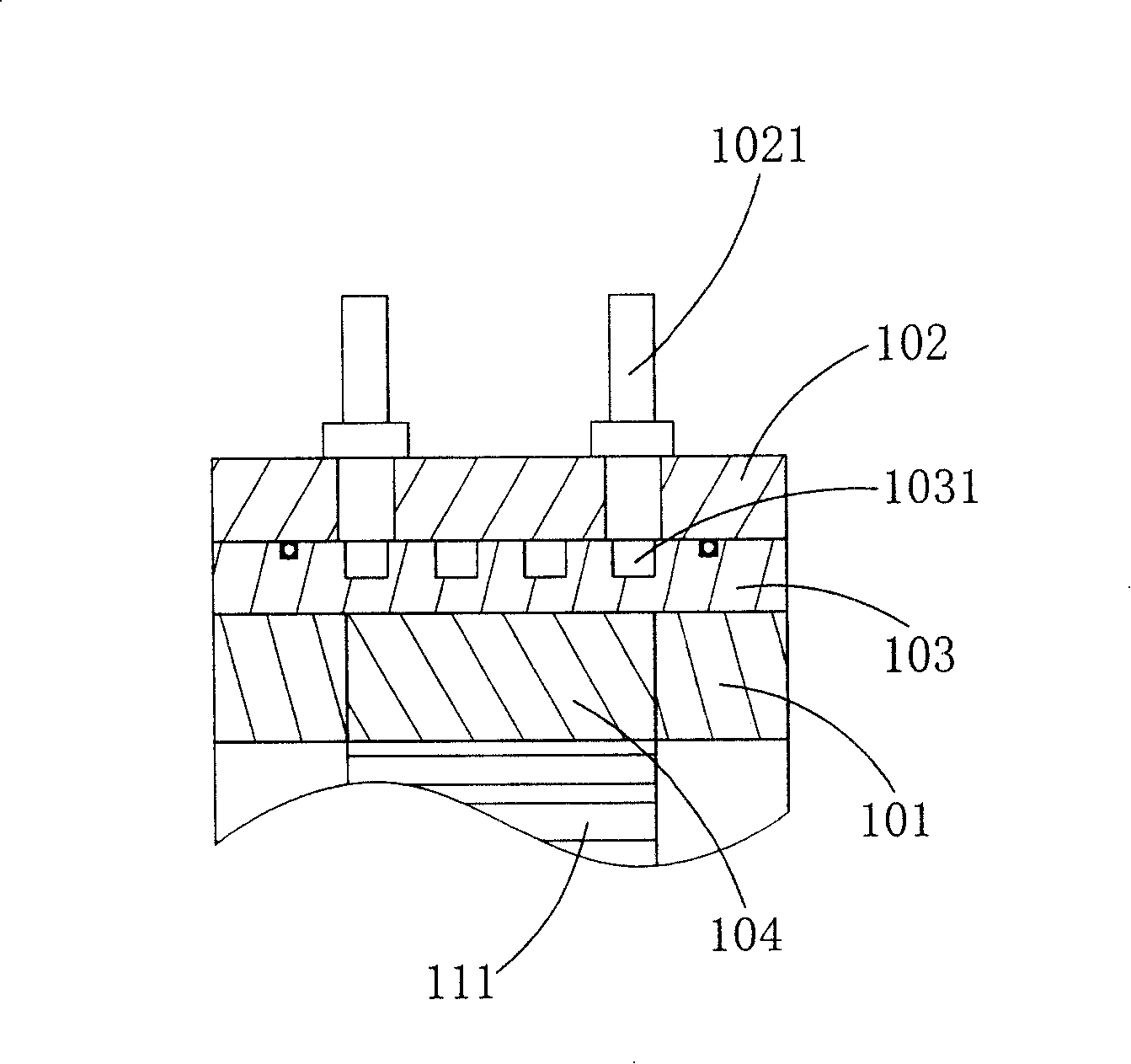

[0037] Such as image 3 , 4 and Figure 5 , the liquid-cooled direct-drive motor stator 20 of the present invention is installed outside the rotor shaft with magnets the same as the existing motor stator. The liquid-cooled direct-drive motor stator of the present invention includes an annular base 21, at least one silicon steel Sheet 22, at least one cooling metal pipe 23 and several coils 24, wherein:

[0038] The annular base 21 is a seat with a space 211 for the operation of the rotor shaft in the center;

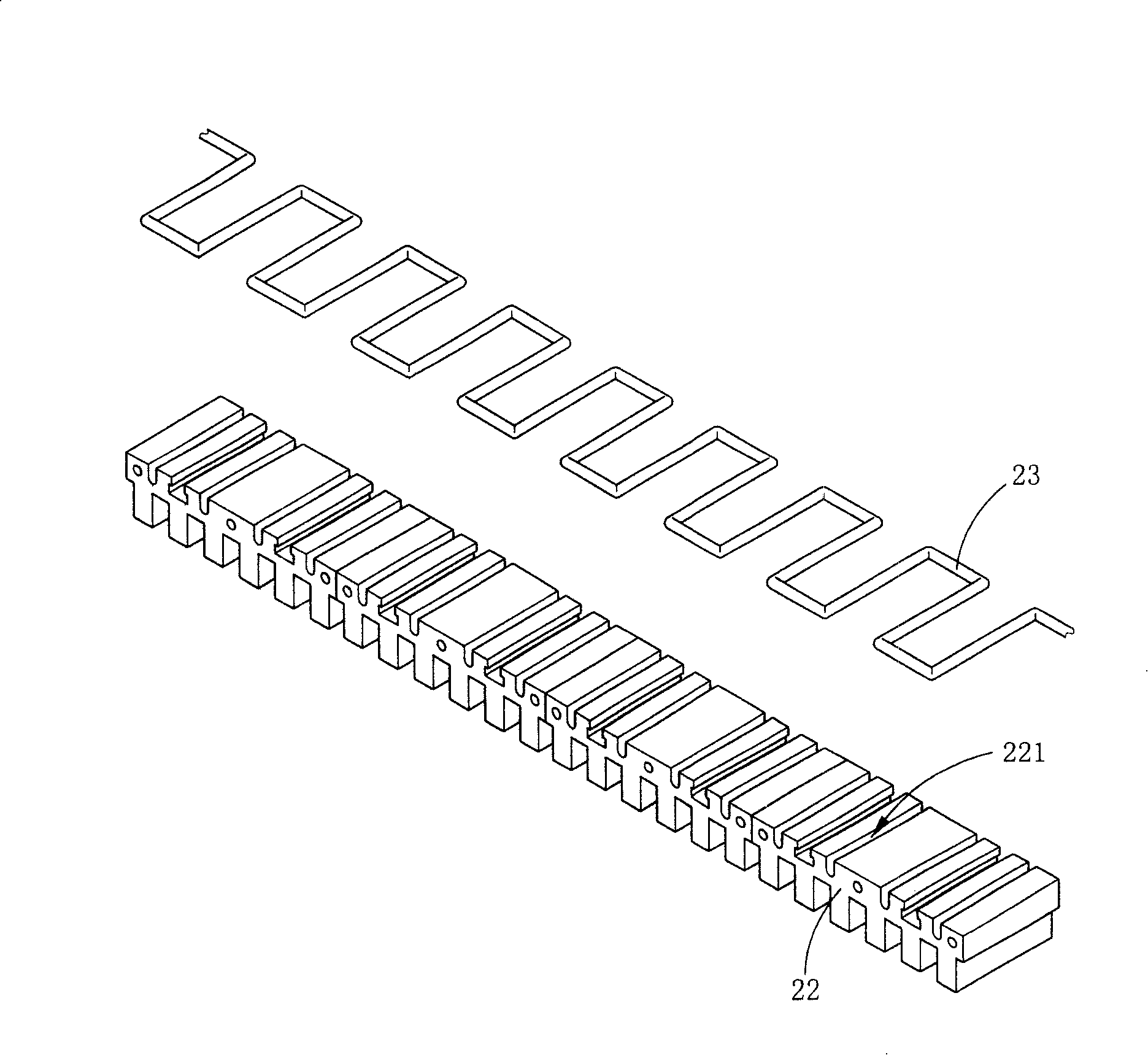

[0039] The silicon steel sheet 22 is positioned on the inner wall of the space 211 of the above-mentioned annular base 21, and the silicon steel sheet 22 is positioned around the outside of the rotor shaft, and the outer surface of the silicon steel sheet 22 is sequentially provided with a plurality of transverse grooves 221. The two ends of the transverse container 221 penetrate outwards;

[0040] The cooling metal pipe 23 and the heat-dissipating metal pipe parts b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap