Ultrasonic machining spindle device

A technology for processing spindles and ultrasonic waves, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of speed limitation, inability to respond to high-speed rotation, wear or damage, etc., and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

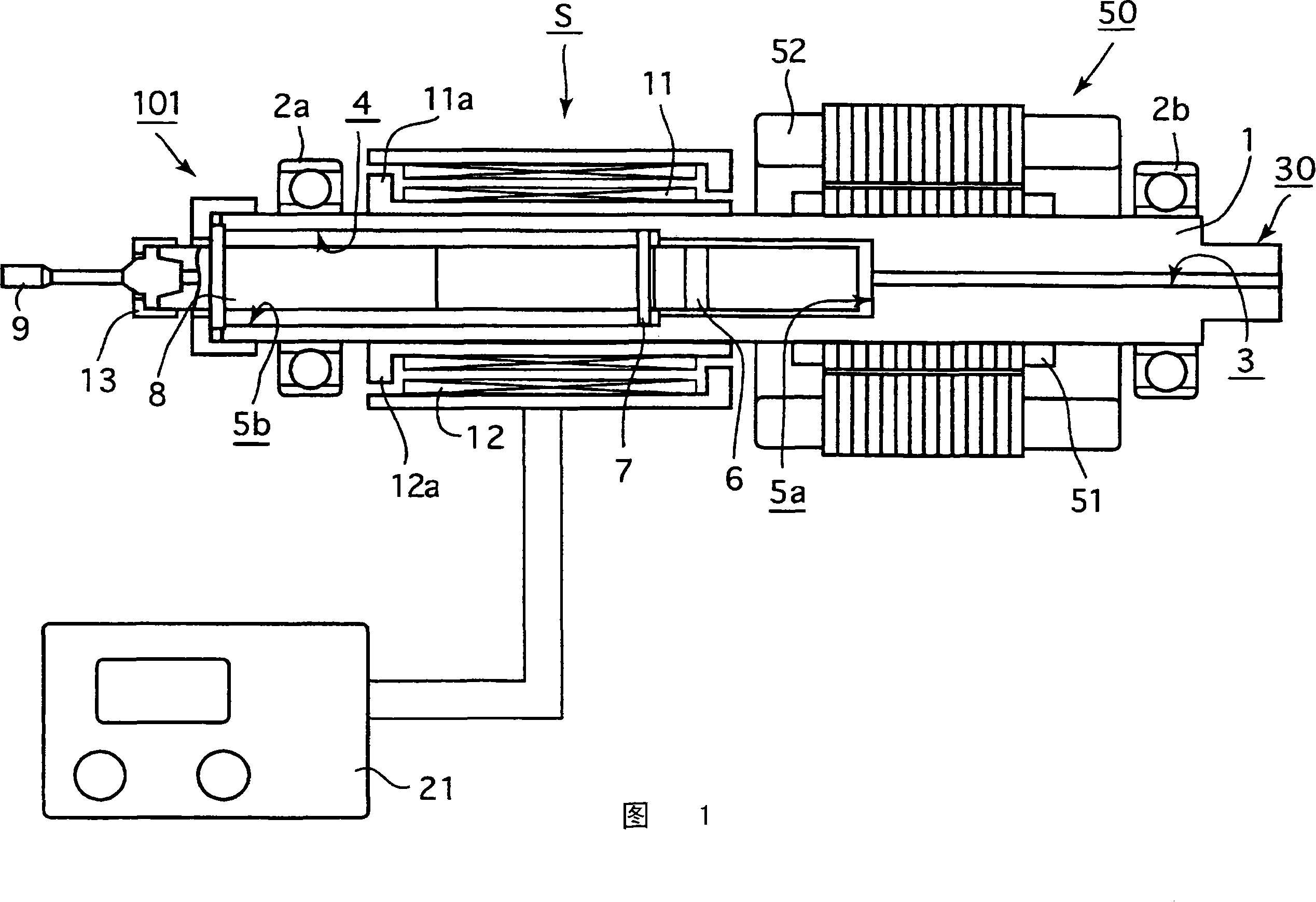

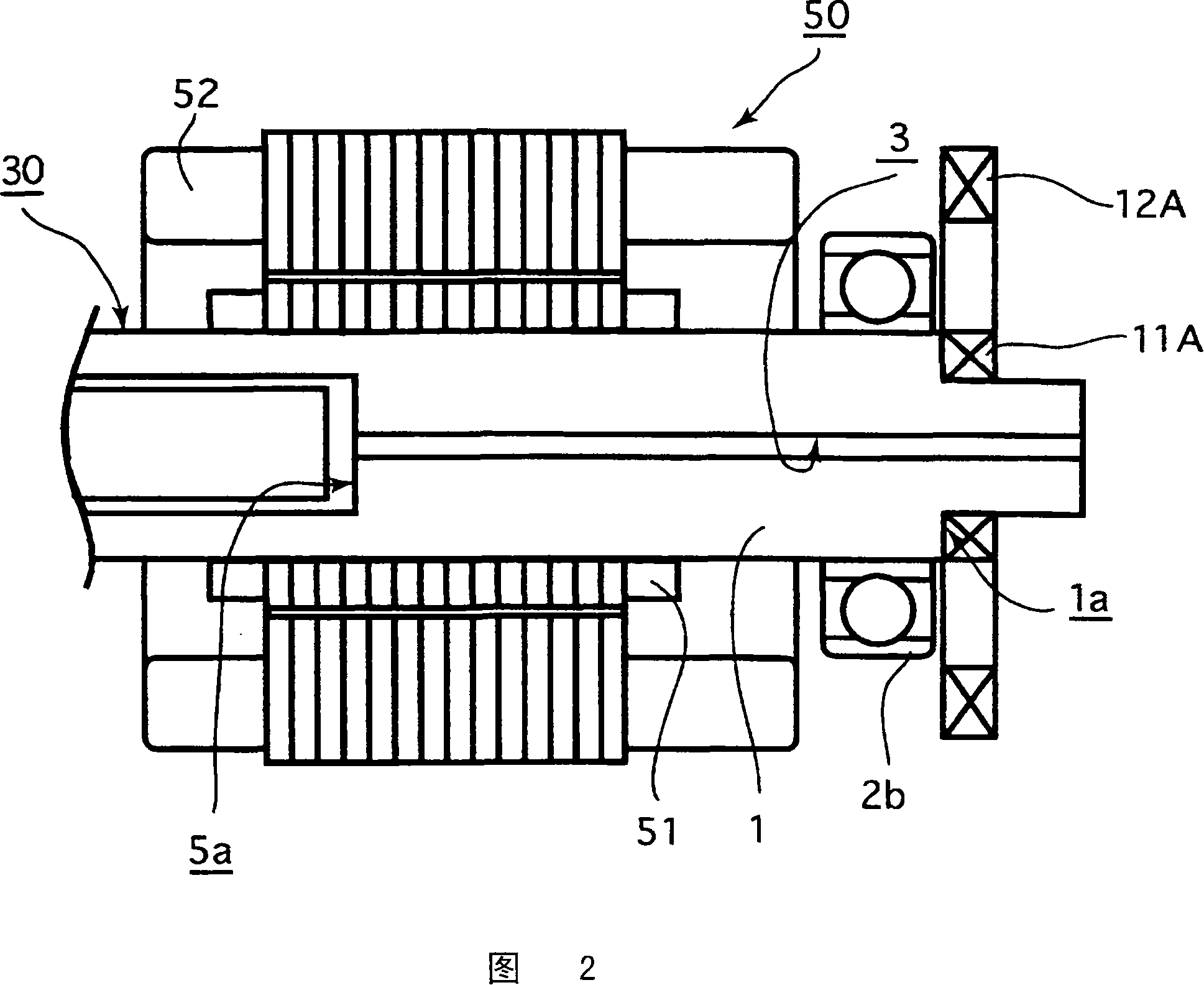

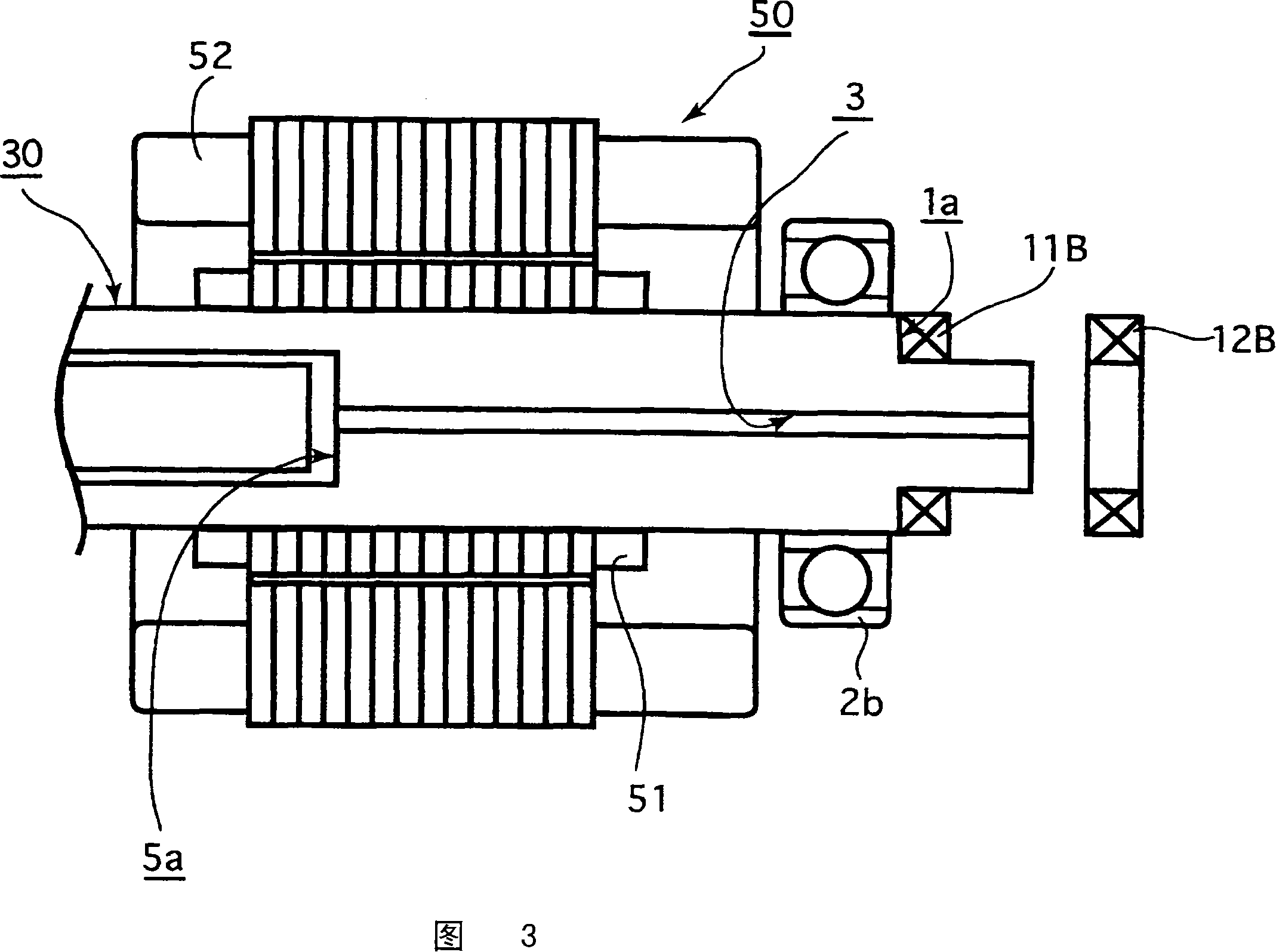

[0026] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

[0027] In addition, members, arrangement|positioning, etc. which are demonstrated below do not limit this invention, Various changes are possible within the scope of the meaning of this invention.

[0028] First, a configuration example of an ultrasonic machining spindle device in an embodiment of the present invention will be described with reference to FIG. 1 .

[0029] 1 shows in particular the structure of the processing spindle 101 and its vicinity, which becomes the main part of the ultrasonic processing spindle device S in the embodiment of the present invention. The processing spindle 101 has a shaft 30 rotatably supported by a bearing 2a or 2b and a The shaft 30 rotates a high-frequency motor 50, and the shaft 30 is provided with a vibrator 6 as an ultrasonic generating element, a horn 8, etc., which will be described later, and in addition, a tool grip for install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com