Motor and its control device

A technology of electric motors and electrical angles, which is applied in the direction of electromechanical devices, electric components, synchronous motors with stationary armatures and rotating magnets, etc., and can solve the problems of reduced productivity of windings, complex structures, and difficulties in miniaturization of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0192] Next, a motor to which an embodiment of the present invention is applied will be described in detail with reference to the drawings.

[0193] First, the conventionally known basic structure of the electric motor of the present invention will be described, and then the structure providing the characteristic features of the present invention will be described.

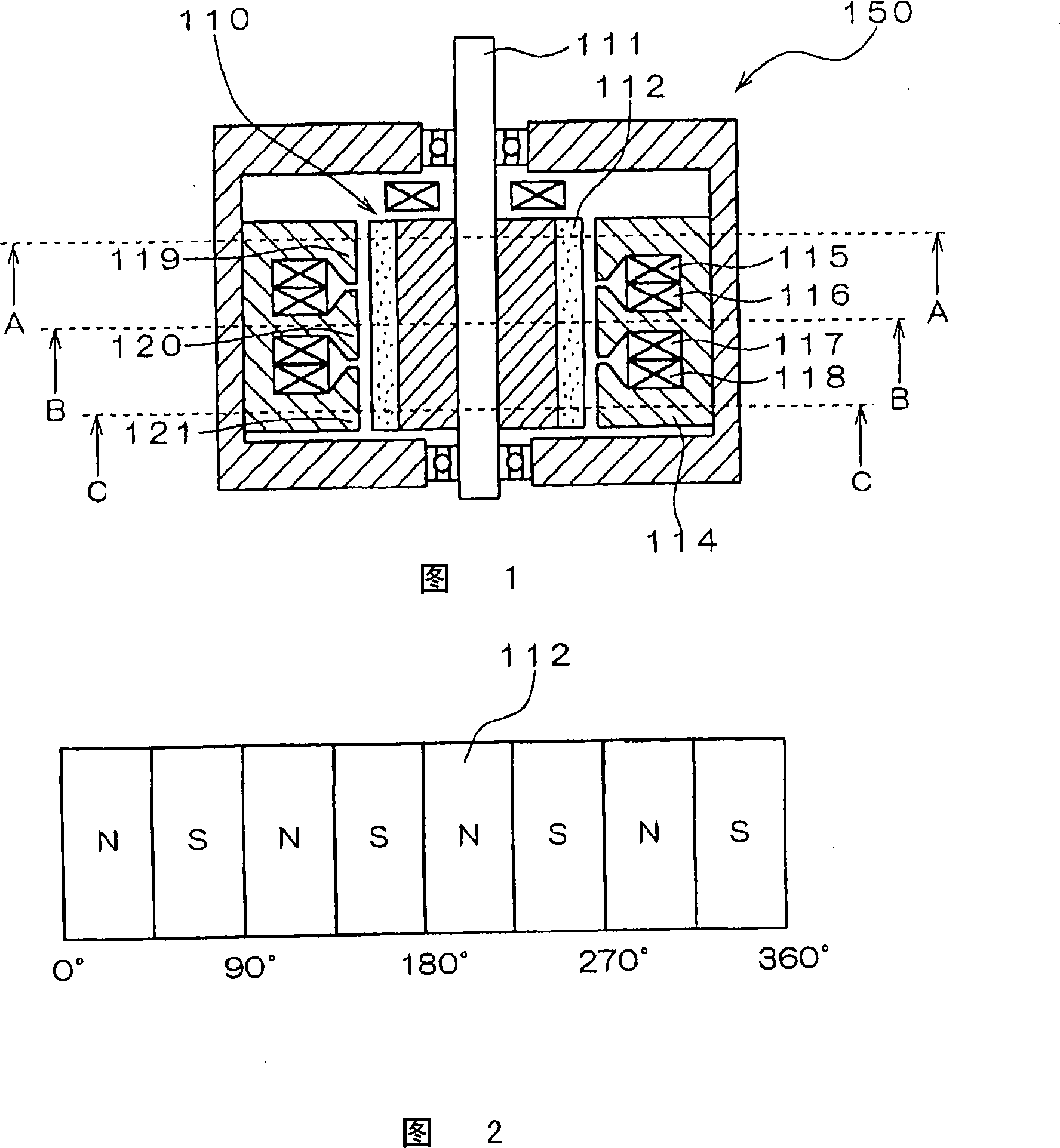

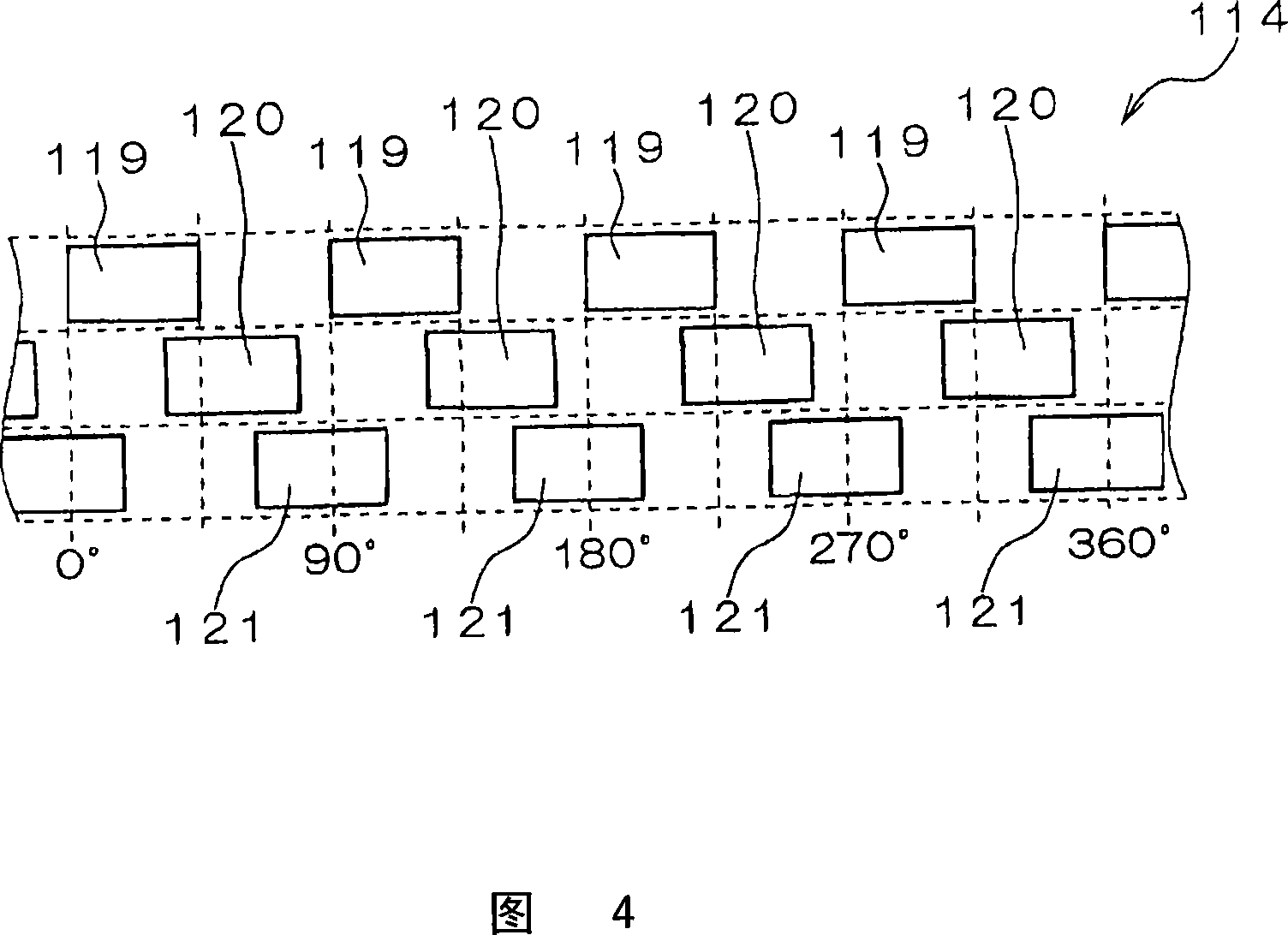

[0194] FIG. 1 is a cross-sectional view showing a basic structure of a brushless motor as a motor of this embodiment. The brushless motor 150 shown in FIG. 1 is an 8-pole motor that operates in 3-phase AC, and includes a rotor shaft 111 , permanent magnets 112 , and a stator 114 .

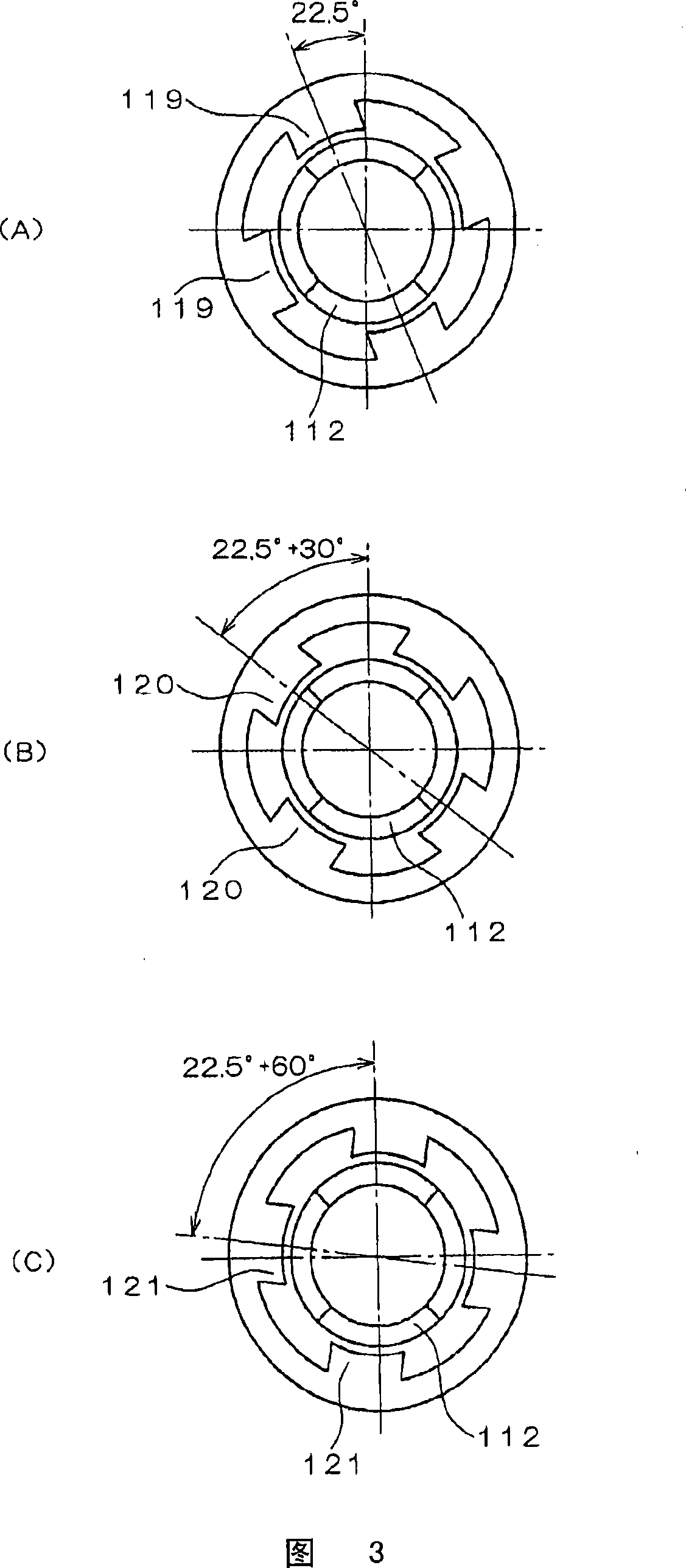

[0195] The rotor 110 has a plurality of permanent magnets 112 arranged on the surface. These permanent magnets 112 are alternately arranged with N poles and S poles in the circumferential direction along the surface of the rotor 110 . FIG. 2 is a developed view of the rotor 110 in the circumferential direction. The horizontal axis r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com