Cement-base infiltration crystallization type water-proof precast product and preparing method thereof

A technology of infiltration crystallization and prefabrication, applied in the field of building materials, can solve the problems of increased construction difficulty, high comprehensive cost, poor durability, etc., and achieve the effects of short construction period, wide application range and low comprehensive cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

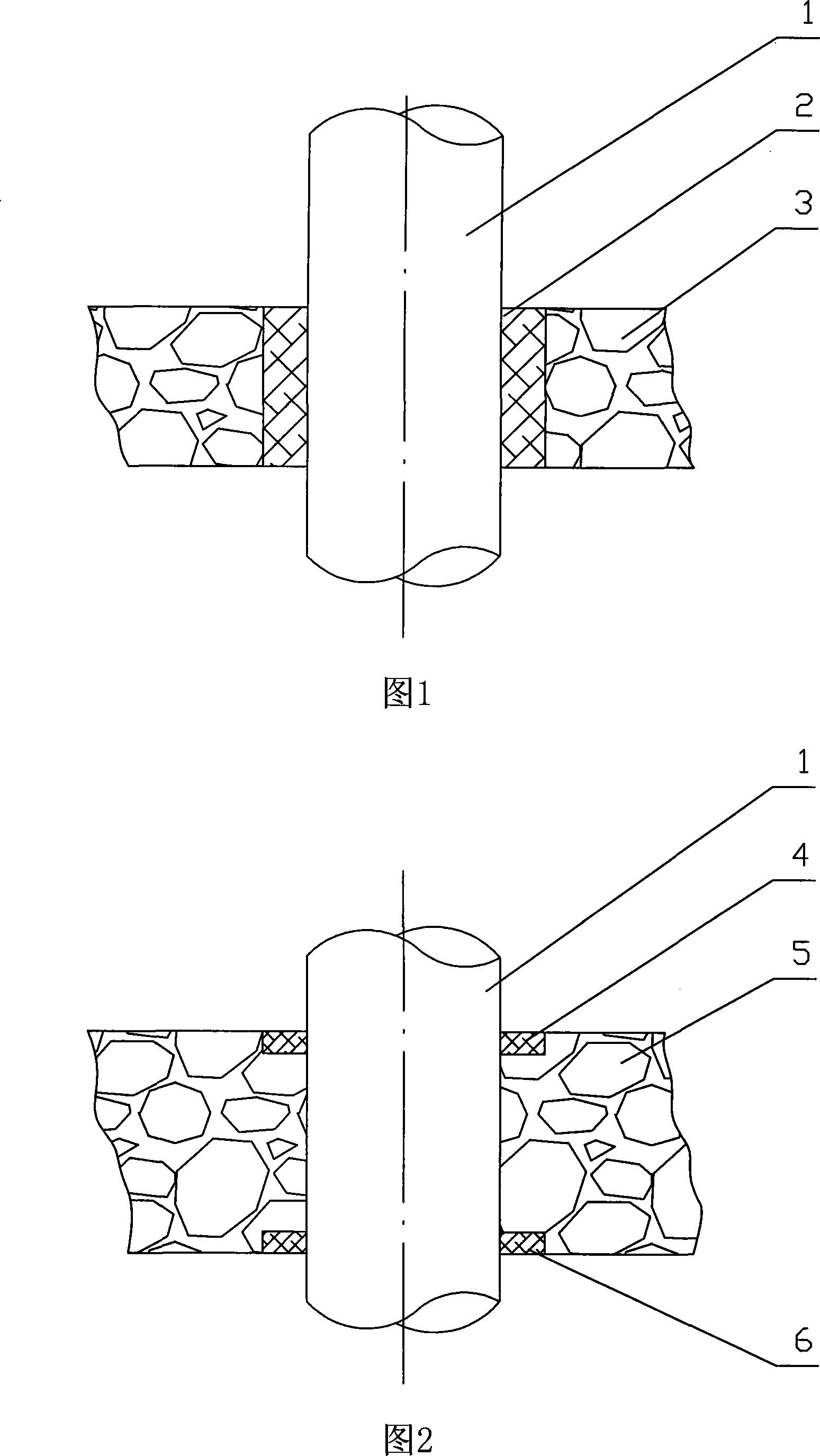

[0032] Embodiment 1: The cement-based osmotic crystalline waterproof prefabricated part of the present invention is composed of osmotic crystalline material, foaming agent, cement, sand, and water, wherein the osmotic crystalline material is purchased from KRYSTOL concrete of the Canadian Krypton International Company For KRYSTOL KIM of the waterproof system, the foaming agent is commercially available, and the weight ratio of each component is: 22 parts of permeable crystalline material, 8 parts of foaming agent, 40 parts of cement, 10 parts of sand, and 20 parts of water; stir after mixing , molded with a model to make a waterproof case. As shown in Figure 1, the cross-section of the waterproof cover 2 is circular, the inner ring is set outside the drain pipe 1 of PVC or iron pipe, the outer ring is connected to the floor layer 3, and cast and fixed on the floor layer 3 at the same time as the drain pipe 1 In the concrete, block the gap between the drainpipe 1 and the concre...

Embodiment 2

[0033] Embodiment 2: The cement-based osmotic crystalline waterproof prefabricated part of the present invention is composed of osmotic crystalline material, foaming agent, cement, sand, and water, wherein the cement-based osmotic crystalline waterproof material is purchased from Canada Krypton (Krypton) International Corporation KRYSTOL T1 of the KRYSTOL concrete waterproofing system, the foaming agent is commercially available, and the weight ratio of each component is: 50 parts of permeable crystalline material, 3 parts of foaming agent, 20 parts of cement, 5 parts of sand, and 22 parts of water; Stir after batching, shape with a model, and make a waterproof ring. As shown in FIG. 2 , the waterproof ring is in the shape of a ring, and is divided into an upper waterproof ring 4 and a lower waterproof ring 6 , which are respectively installed at the upper and lower openings of the drain pipe 1 . During installation, they are fitted with the drainpipe 1 respectively, and then ...

Embodiment 3

[0034] Embodiment 3: The cement-based osmotic crystalline waterproof prefabricated part of the present invention is composed of osmotic crystalline material, foaming agent, cement, sand, and water, wherein the osmotic crystalline material is purchased from Xinhan Kamis (International) Waterproof Technology Development Company , the foaming agent is commercially available, and the weight ratio of each component is: 2 parts of permeable crystalline material, 15 parts of foaming agent, 30 parts of cement, 30 parts of sand, and 23 parts of water; Form a square waterproof block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com