High and low ridge underflow stilling basin

A stilling pool and bottom flow technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as water surface fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

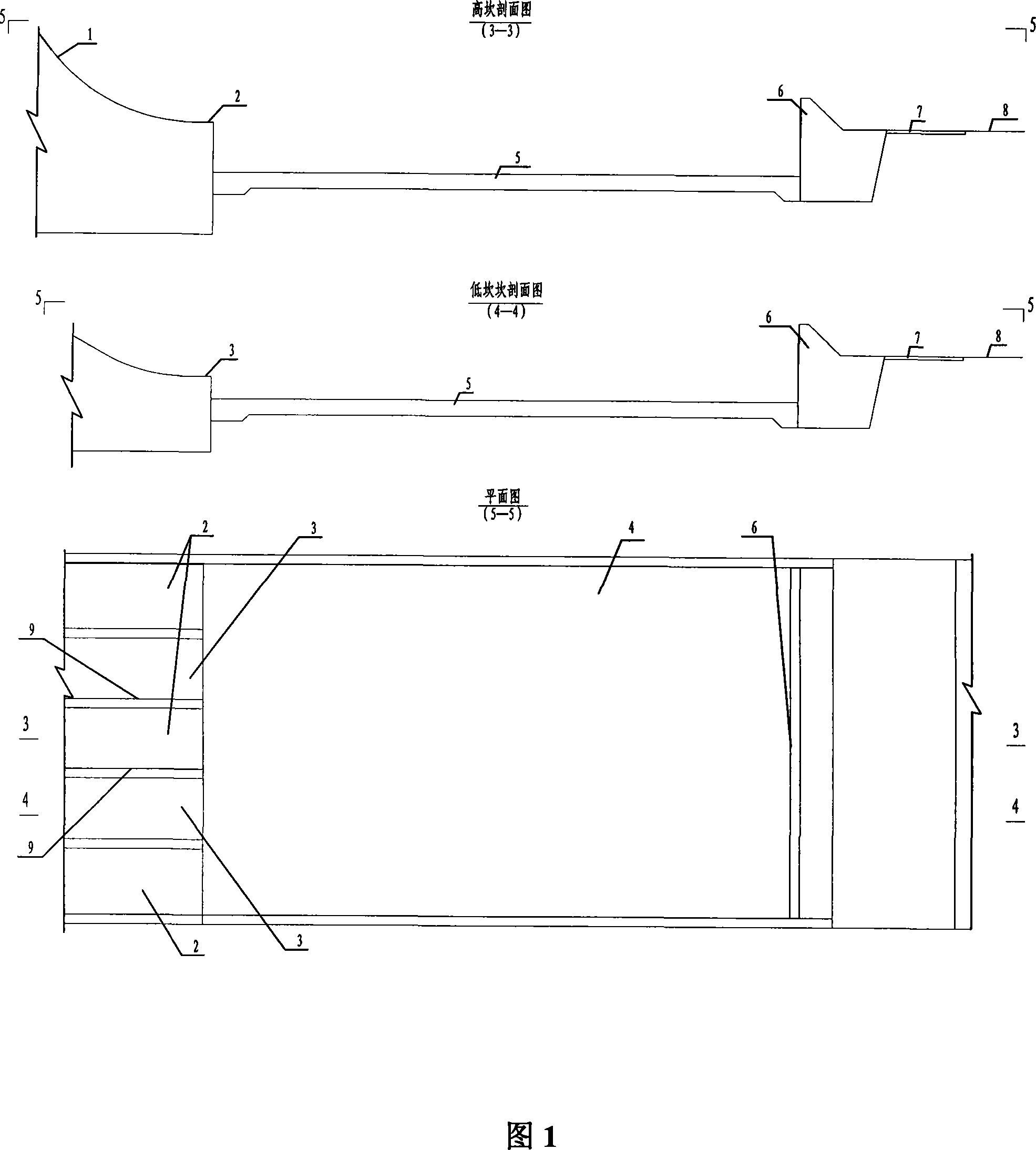

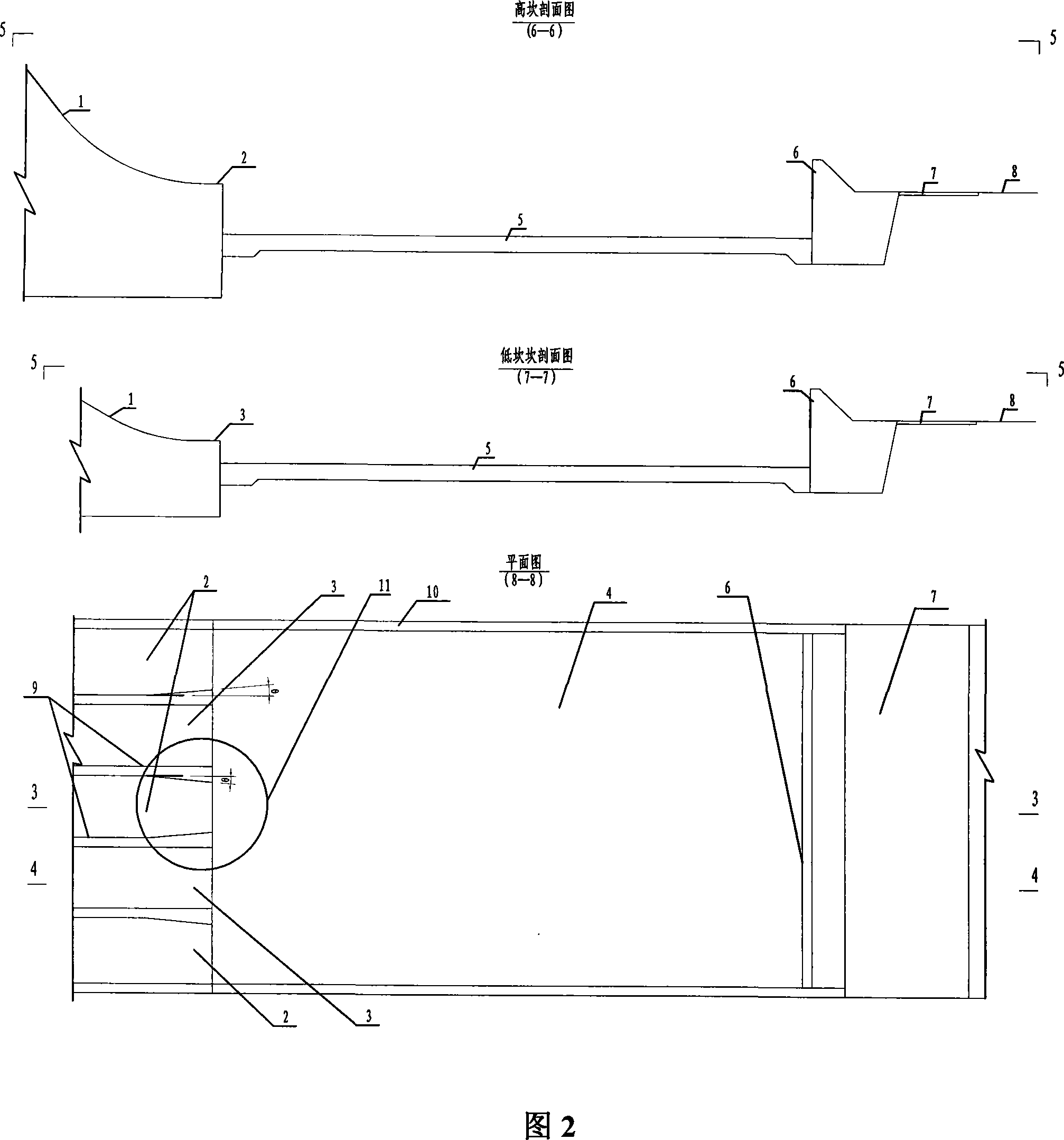

[0028] A large-scale hydropower station project with an installed capacity of 6400MW uses a concrete gravity dam with a maximum dam height of 162m. The design flood (P=0.2%) enters the flood peak discharge of 41200m 3 / s, check flood (P=0.02%) inbound flood peak flow 49800m 3 / s. Among them, the water level difference between the upstream and downstream is about 85m in the case of flood verification, the maximum total discharge power is about 40,000MW, and the maximum single-width flow in the stilling pool is 225m 3 / s, the flow velocity of the stilling pool into the pool reaches 38m / s~42m / s.

[0029] Due to the limitation of environmental conditions, high and low bottom flow stilling pools are used for energy dissipation. The length of the stilling pool is 228m, and there is a central guide wall in the pool, which is divided into two symmetrical energy dissipation areas. The floor elevation of the consumption pool is 245m, and the elevation of the end sill is 270m.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com