Straight six-cylinder car engine exhausting pipe system

A technology for automobile engines and exhaust pipes, applied to engine components, machines/engines, exhaust devices, etc., can solve the problems of shortened service life of exhaust manifolds, difficult manufacturing, complex design, etc., and improve exhaust purification efficiency , improve exhaust uniformity, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

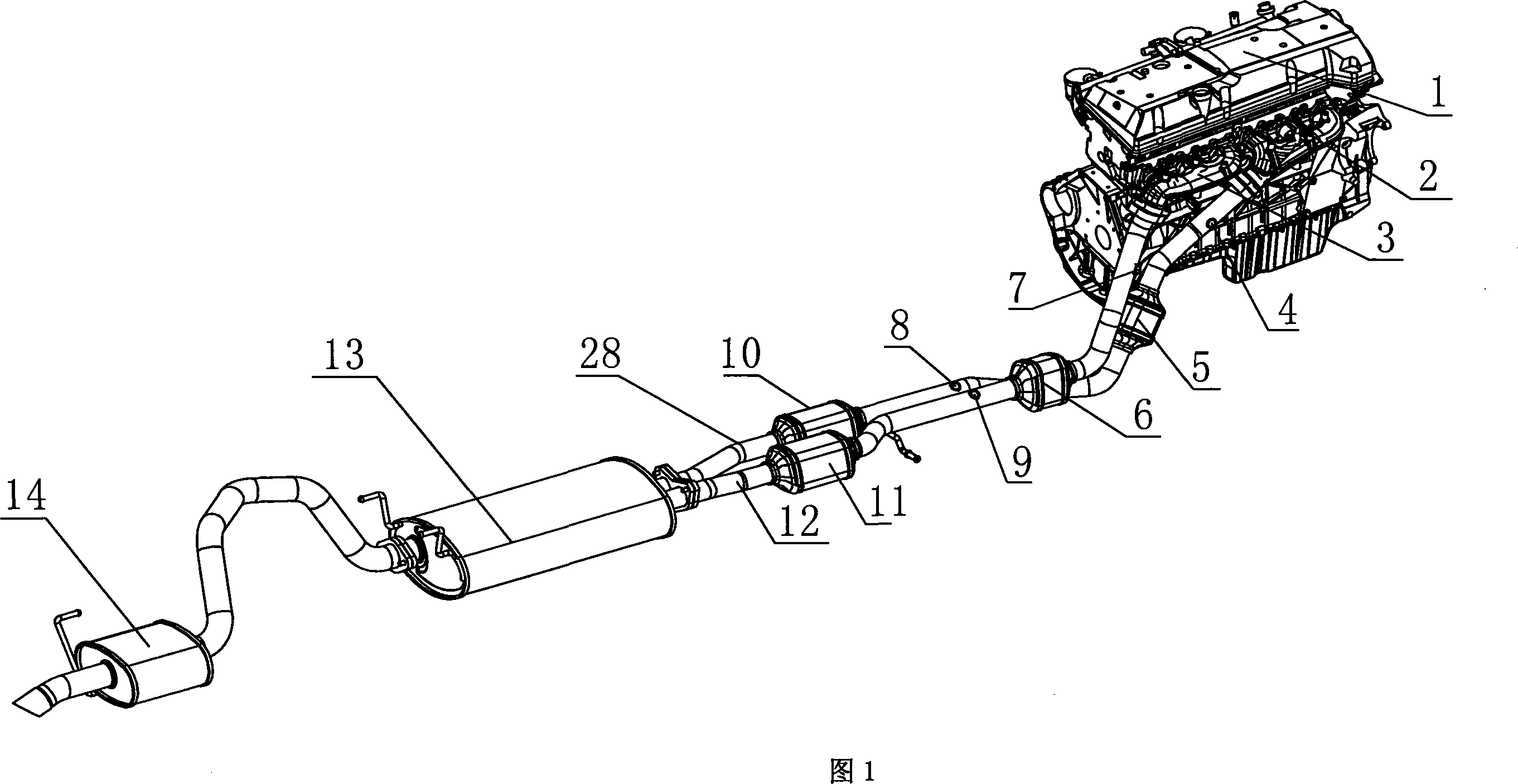

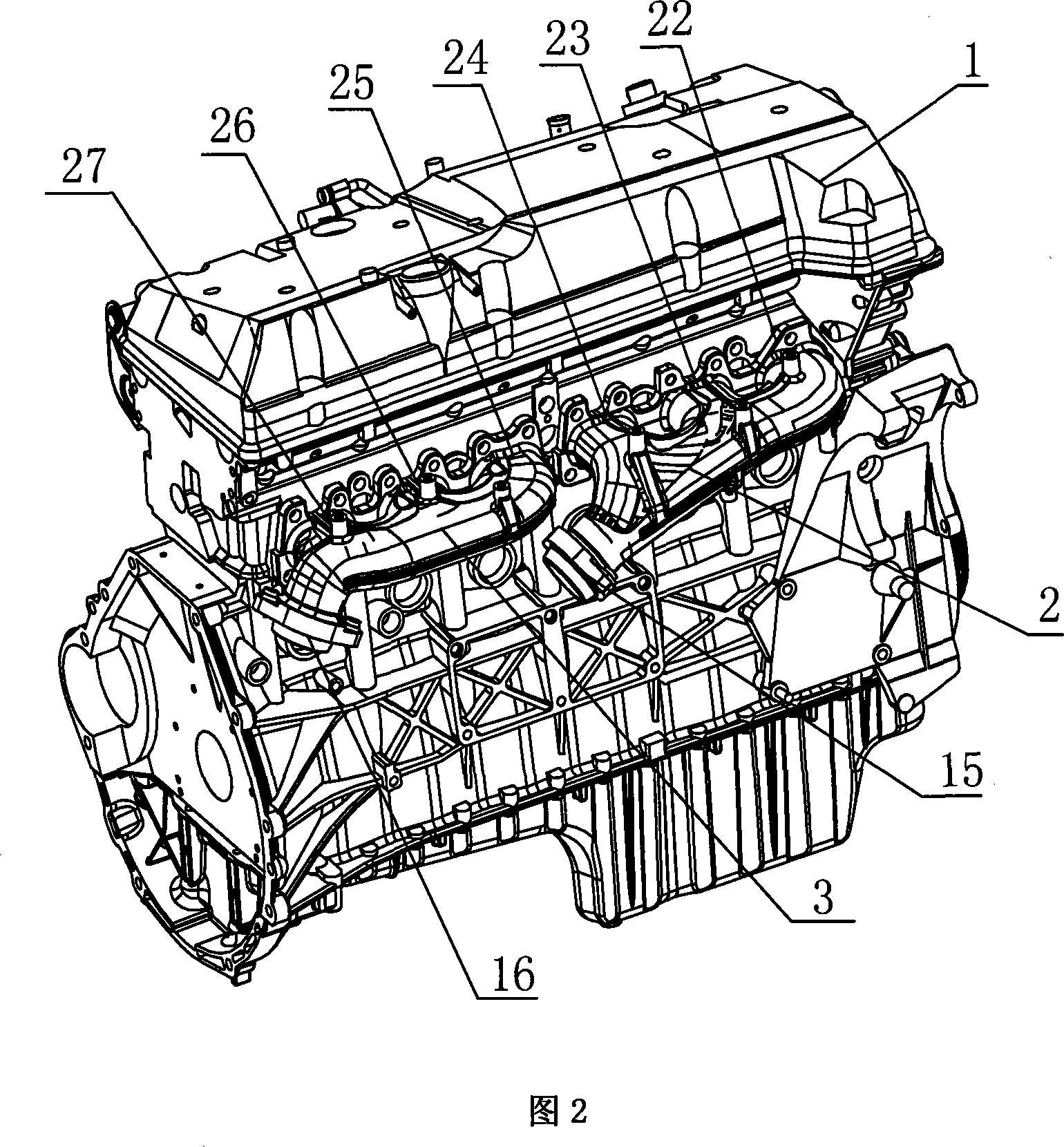

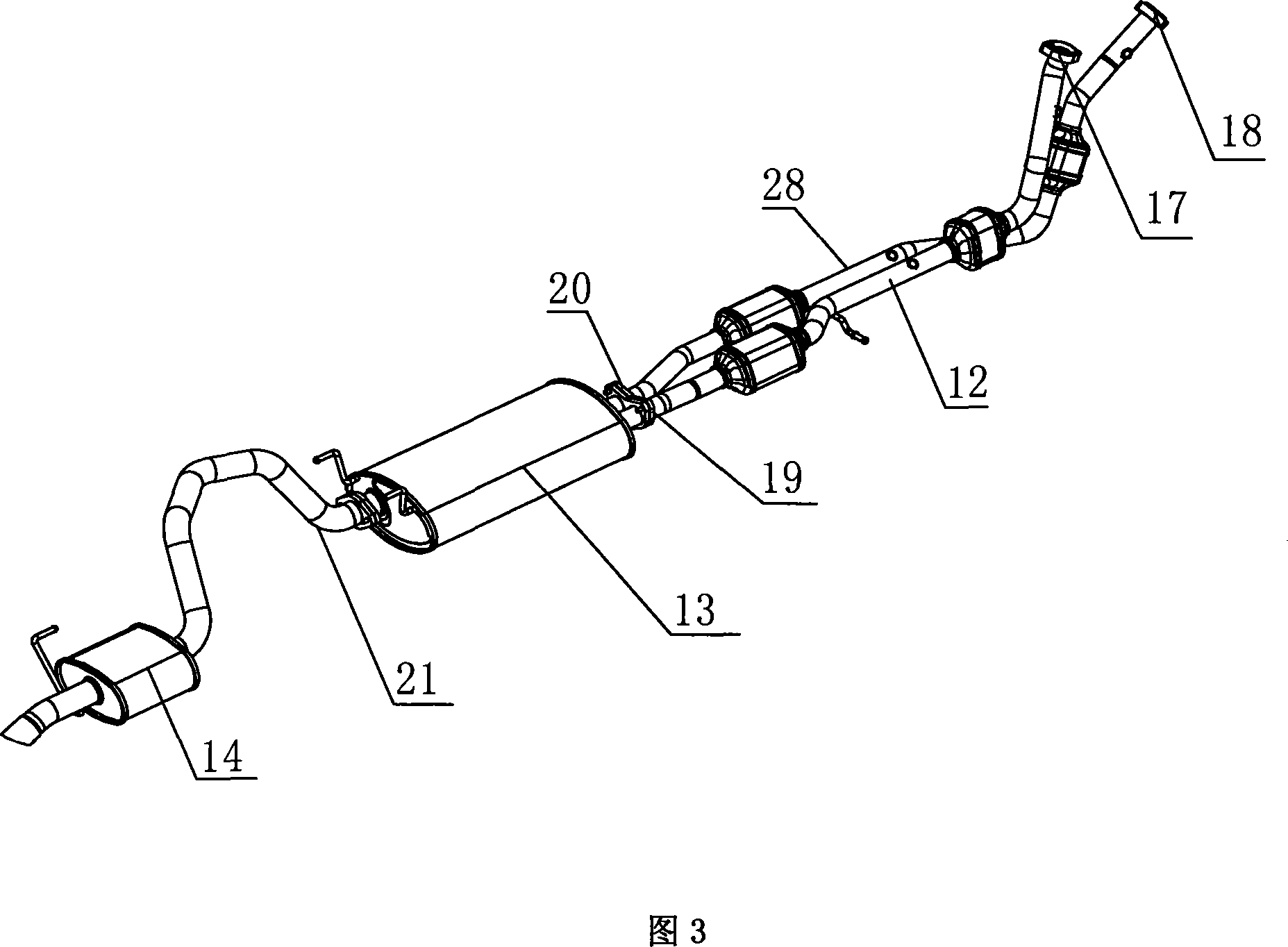

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the upright six-cylinder automobile engine 1 is provided with six exhaust ducts, and three exhaust ducts 22, 23, 24 form a group with the first exhaust manifold 2 connected, the exhaust gas discharged from these three exhaust passages joins in the first exhaust manifold 2; the other three exhaust passages 25, 26, 27 form a group and connect with the second exhaust manifold 3, from Exhaust gases discharged from these three exhaust passages are combined in the second exhaust manifold 3 .

[0017] The first exhaust branch pipe 28 is connected to the first exhaust manifold 2 through the flange mounting end faces 18, 15, the second exhaust branch pipe 12 is connected to the second exhaust manifold 3 through the flange mounting end faces 17, 16, The exhaust gases are then discharged into two exhaust manifolds. A front catalytic converter 5, 6 and a rear catalytic converter 10, 11 are respectively installed in each exhaust branch pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com