Piezoelectric stack pump

A piezoelectric stacking and stacking technology, which is applied in the direction of pumps, piezoelectric devices/electrostrictive devices, pumps with flexible working elements, etc., can solve the problem that the output displacement is easily affected by the load, the output force of the piezoelectric sheet is small, Low output accuracy and other issues, to achieve the effect of simple structure, increased frequency and output pressure, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

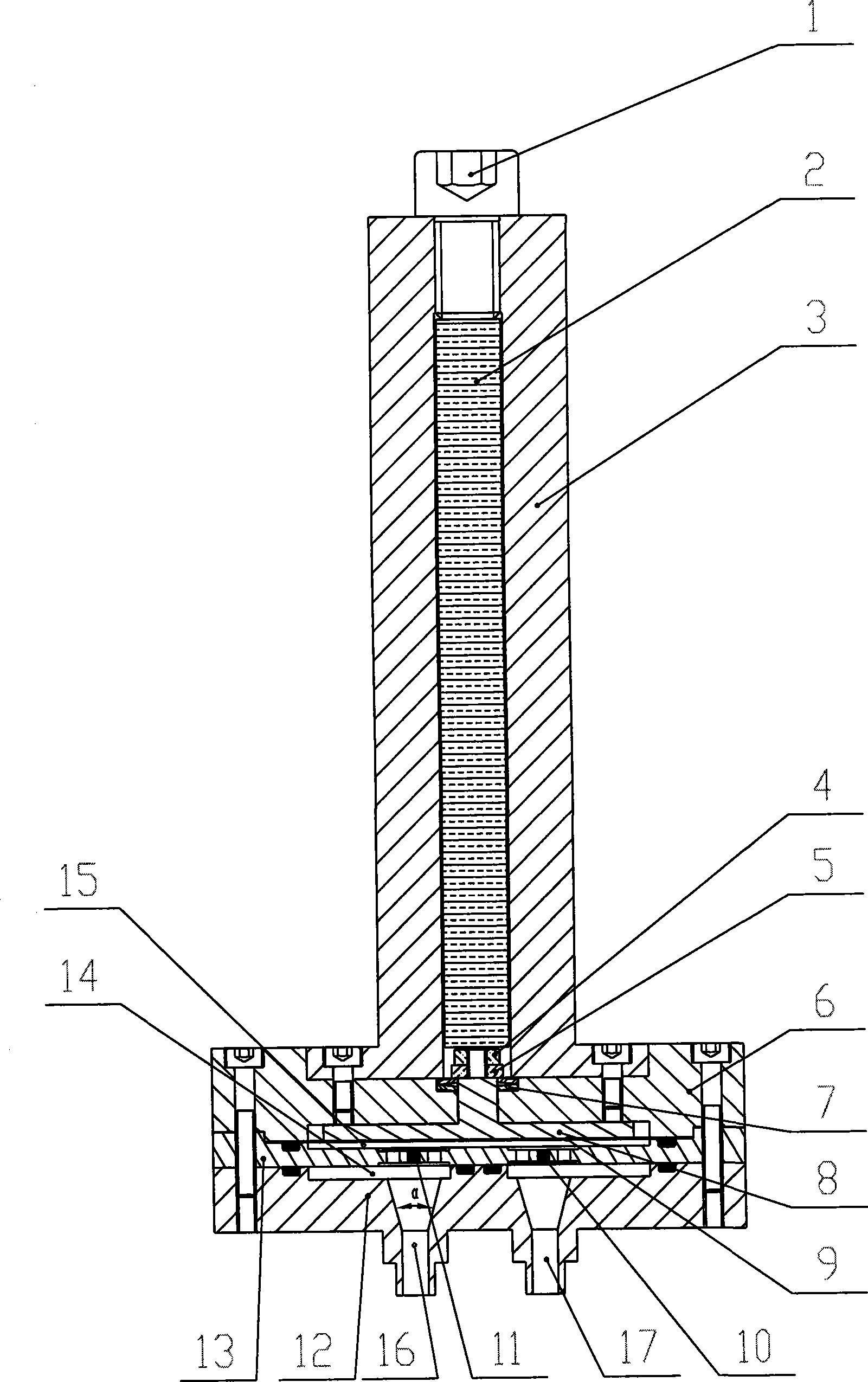

[0008] The stack support body 3 is fixedly connected with the support 6, a set of butterfly springs 7 is sleeved on the piston, the fixed nut 1 4 and the fixed nut 2 5 are threadedly connected with the piston, and the piezoelectric stack 2 is placed on the fixed nut 1 4 , the pre-tightening screw 1 is fixedly connected to the rear of the stacked support body 3, the lower cover 12 is fixedly connected to the valve seat 13, the metal sealing diaphragm 9 and the support, the piston 8 is fixedly bonded to the metal sealing diaphragm, and the water inlet is single The directional valve 11 is fixedly connected with the valve seat, the water outlet check valve 10 is fixedly connected with the valve seat, the metal sealing diaphragm and the valve seat form a working chamber 15, a buffer chamber 14 is formed between the lower cover and the valve seat, and there is a water inlet on the lower cover 16 is connected with the water outlet 17 and the buffer chamber respectively, and the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com