Barrel-type friction-changing damper

A variable friction and damper technology, applied in the direction of friction shock absorbers, etc., can solve the problems of high cost, fixed maximum value, difficulty in meeting large tonnage and large deformation capacity at the same time, and achieve the goal of improving output tonnage and large displacement capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this example, Teflon (Teflon) coating is used as the inner wall contact surface of the second friction sleeve 17 .

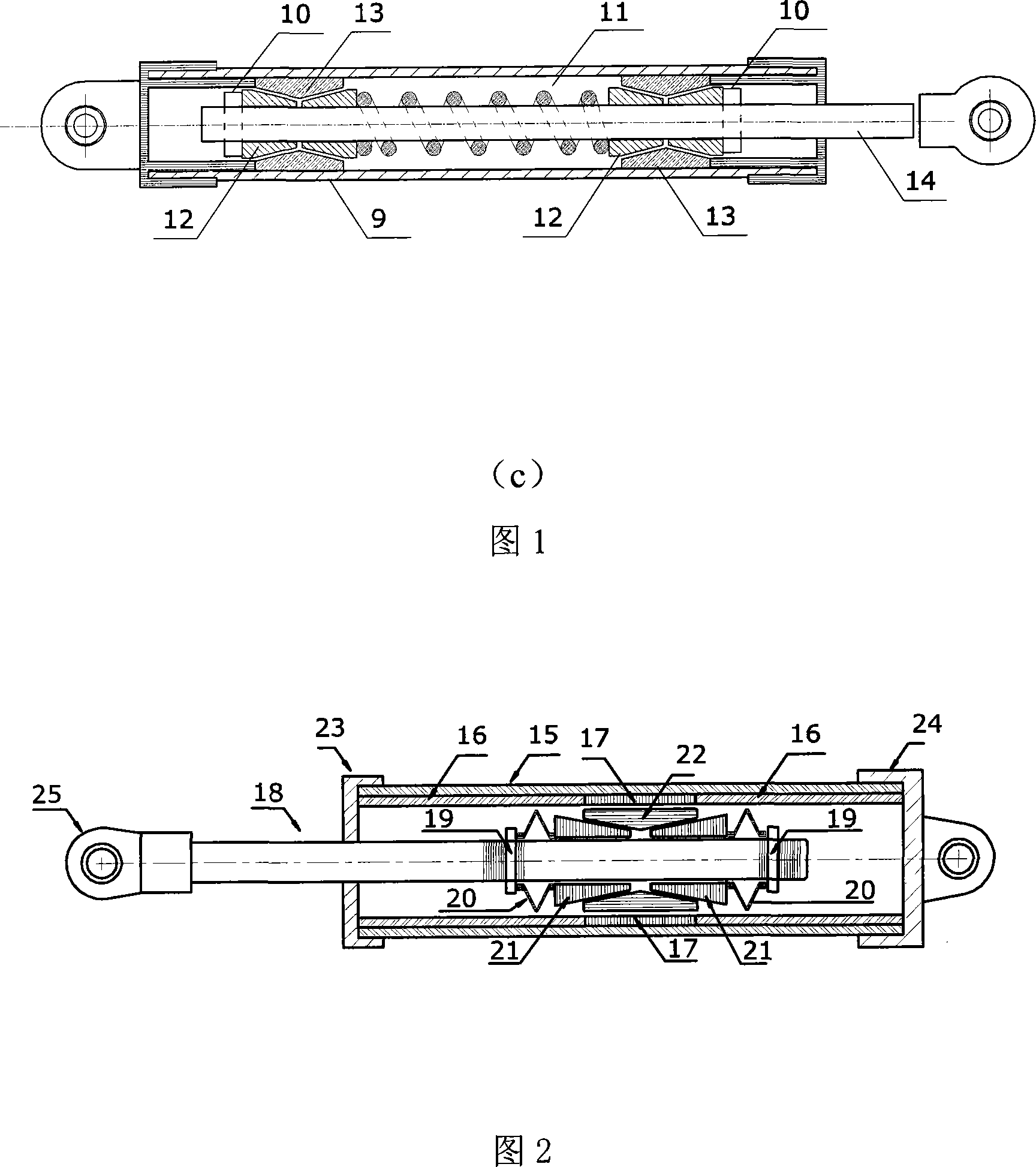

[0043] As shown in FIG. 11 , two first friction sleeves 16 are connected to two ends of a second friction sleeve 17 respectively, and the outer sleeve 15 is sleeved on the outer walls of the above three friction sleeves. The outer diameters of the first friction sleeve 16 and the second friction sleeve 17 are the same, which are both equal to the inner diameter of the outer sleeve 1 . The part where the second friction sleeve 17 contacts the friction slider 22 is located on the same cylindrical surface as the inner wall of the first friction sleeve 16 . The friction coefficient of the contact surface between the inner wall of the second friction sleeve 17 and the friction slider 22 is smaller than the friction coefficient of the contact surface between the inner wall of the first friction sleeve 16 and the friction slider 22 . In this embodiment, the ...

Embodiment 2

[0049] As shown in FIG. 10 , balls 30 are embedded in the inner wall of the second friction sleeve 17 in this embodiment, and other components are the same as those in Embodiment 1.

[0050] The width of the friction surface of the friction slider 22 is equal to the height h of the second friction sleeve 17 , as shown in FIG. 11 . The contact position between the ball 30 in the second friction sleeve 17 and the friction slider 22 is located on the same cylindrical surface as the inner wall of the first friction sleeve 16 . The rolling friction coefficient of the contact surface between the friction slider 22 and the second friction sleeve 17 is less than 0.01 times of the friction coefficient of the contact surface between the friction slider 22 and the first friction sleeve 16 .

[0051] Initially, the friction slider 22 is aligned with the second friction sleeve 17, as shown in FIG. 11 . When the damper is deformed, the contact area between the friction slider 22 and the co...

Embodiment 3

[0053] As shown in FIG. 13 , the width of the friction surface of the friction slider 22 in this embodiment is greater than the height h of the second friction sleeve 17 . All the other parts are the same as in Example 2.

[0054] Initially, the friction slide 22 is aligned with the second friction sleeve 17 . Since the width of the friction slider 22 is greater than the height h of the second friction sleeve 17, when the friction slider 22 moves from the initial position relative to the second friction sleeve 17, the friction resistance of the damper will remain unchanged until the friction One end of the slider 22 enters the range of the second friction sleeve 17, as shown in FIG. 15 , after that, the frictional resistance of the damper will increase linearly as the relative displacement continues to increase. Therefore, the hysteresis curve of Example 3 will be as shown in FIG. 16 .

[0055] The application form of the cylindrical friction damper proposed in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com