Hydraulic-mechanical transmission engineering machinery automatic shifting speed variator and control method

A technology of automatic shifting and transmission engineering, applied in transmission control, mechanical equipment, components with teeth, etc., can solve the problems of increasing unsafe factors, distracting drivers, frequent shifting operations, etc., to reduce shifting. The effect of gear shift labor intensity, stable and fast automatic gear shifting, and preventing the effect of starting the car in gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to further understand the content, characteristics and effects of the present invention, the following examples of the electro-hydraulic shifting transmission device with an electronically controlled engine are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings:

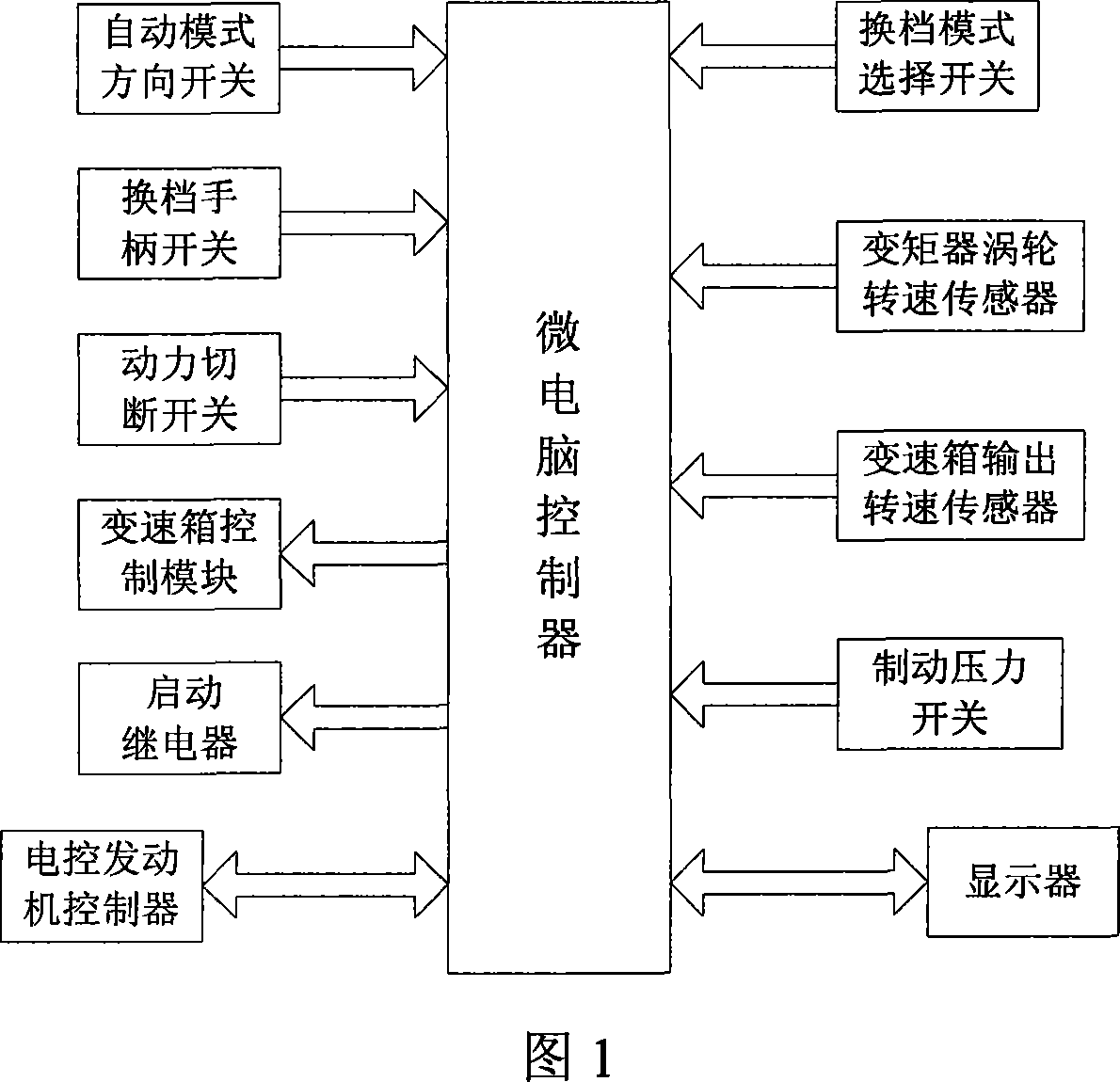

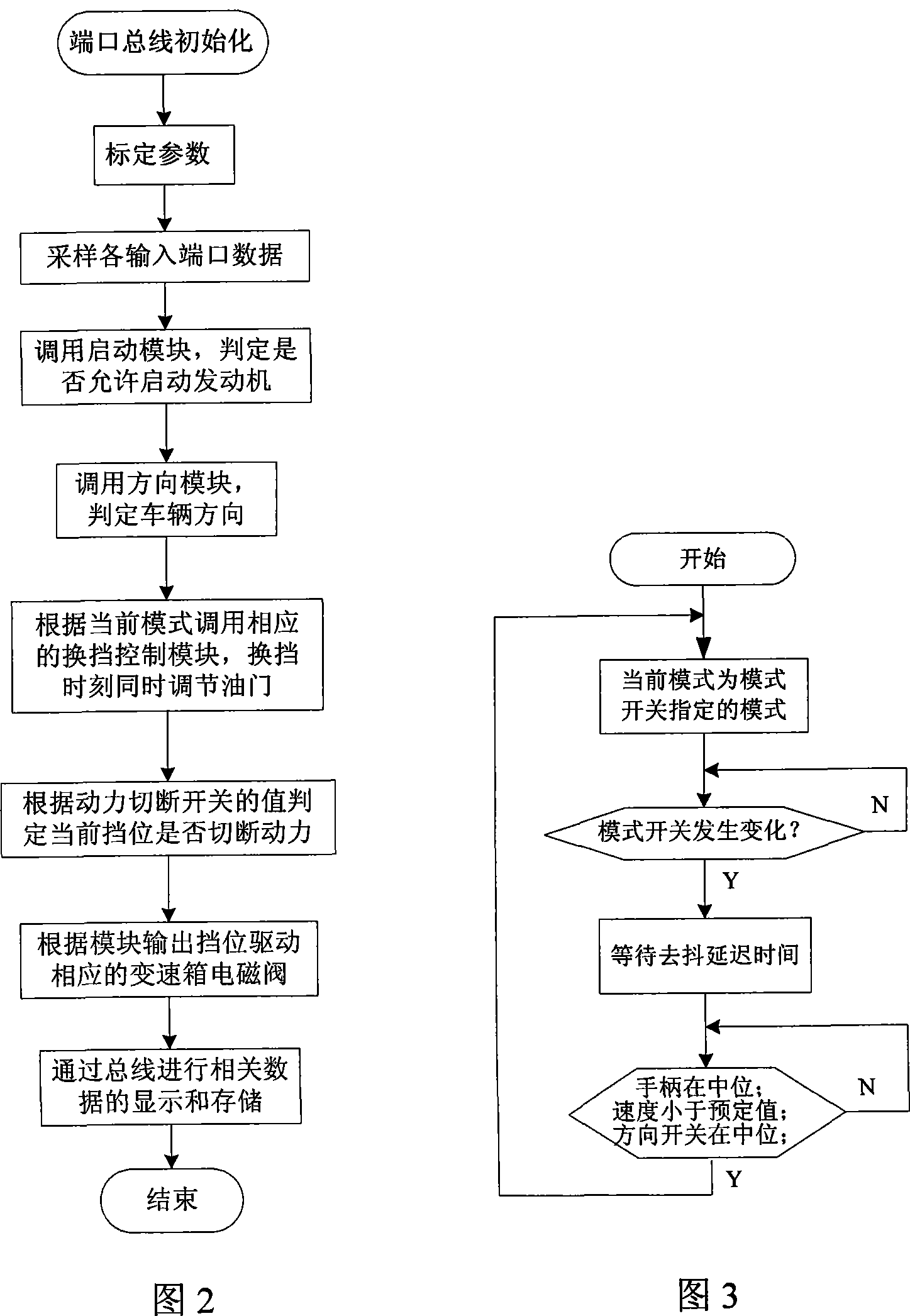

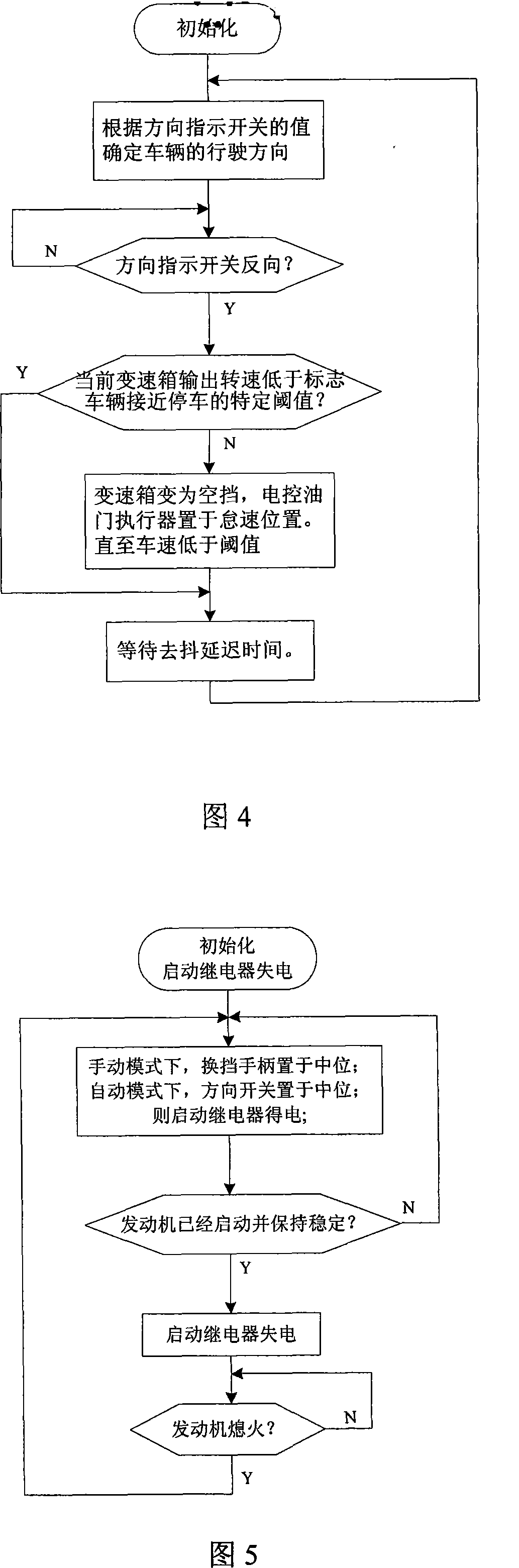

[0065] As shown in Figure 1, the device includes an electro-hydraulic gearshift transmission device, a microcomputer controller, an electronically controlled engine controller, a gearbox output speed sensor, a torque converter turbine speed sensor (the transmission ratio of each gear of the gearbox can also be used) , the torque converter turbine speed is obtained by calculating the output speed of the gearbox, thereby omitting the sensor), shift handle switch, shift mode selection switch, automatic mode direction switch, brake pressure switch, start relay, brake power cut-off switch. The electronically controlled engine controller communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com