Optical waveguides ring-shaped resonant cavity elementary structure parameter test device and its method

A ring-shaped resonant cavity and basic structure technology, which is applied in the testing of machine/structural components, measuring devices, optical waveguides and light guides, etc., can solve the problems of poor repeatability, low calculation accuracy, and complex testing devices, and improve the limit sensitivity. , the effect of low calculation accuracy, important scientific significance and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

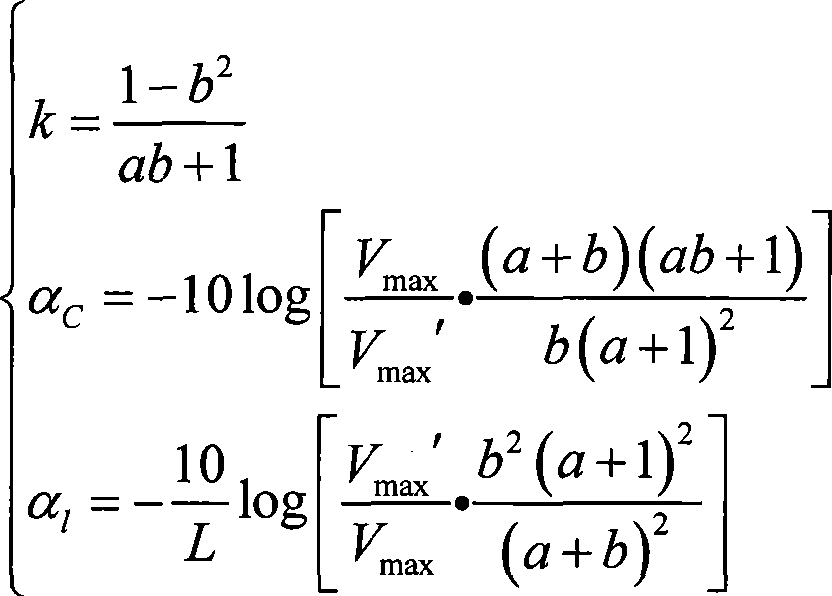

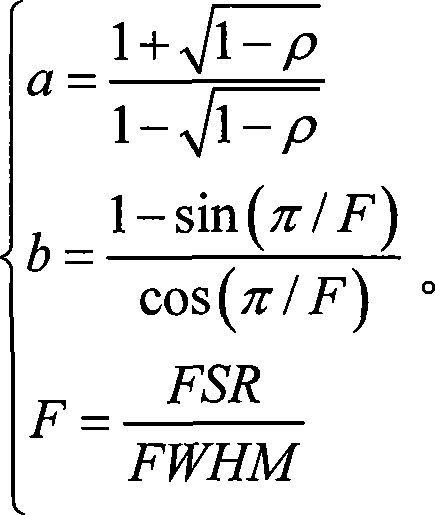

[0022] In the present invention, by testing the resonance curve of the optical waveguide ring cavity and the average output amplitude of three reference straight waveguides, the three basic structural parameters of the optical waveguide ring resonator, including coupler coupling coefficient and additional loss, and waveguide transmission loss are completely independent Calculated. The main reason for using three reference straight waveguides is to use the alignment characteristics of the ribbon fiber to reduce the test error and improve the accuracy of the basic structural parameters of the test optical waveguide ring resonator. According to the three parameters obtained from the resonance curve output by the light wave after the transmission of the ring resonator: the definition of the resonance depth ρ, the free spectral line width FSR of the resonator and the full width at half maximum FWHM of the resonator spectral line, the optical waveguide ring is obtained by using the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com