Acoustic absorbent high-temperature sound absorption performance test apparatus

A technology of sound-absorbing materials and testing devices, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of not being able to test the sound-absorbing performance of sound-absorbing materials in high-temperature fields, and achieve the effects of simple structure, easy manufacture, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

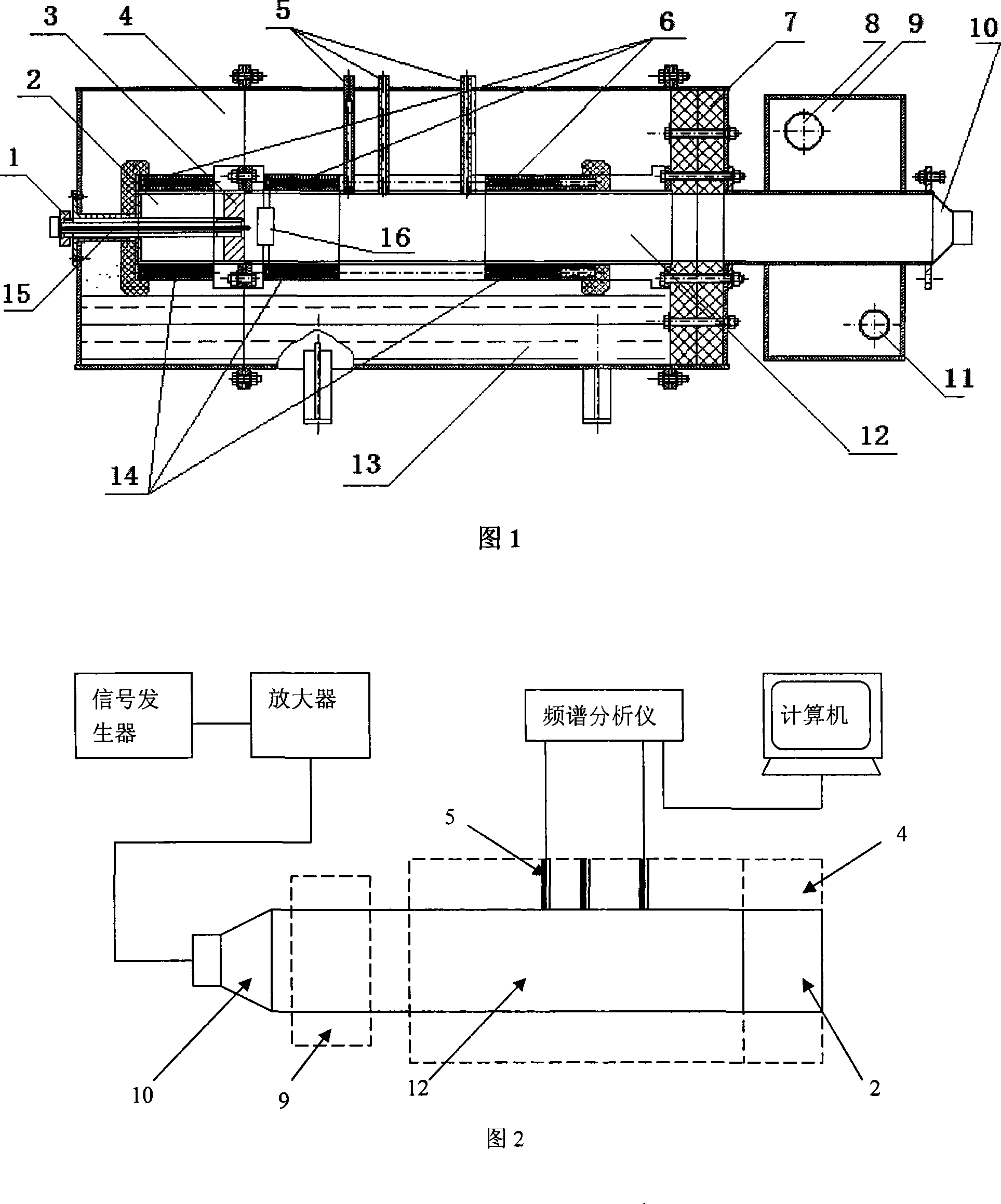

[0016] As shown in Figure 1 and Figure 2, a high-temperature sound-absorbing performance testing device for sound-absorbing materials includes an impedance tube system and a heating and cooling system, wherein: the impedance tube system includes an impedance tube 12 made of stainless steel tubes, installed in the impedance The test piece cylinder 2 at one end of the tube, the sound source speaker 10 installed at the other end of the impedance tube, the speaker 10 is connected to the signal generator (generating white noise signal) through an amplifier, three holes are opened at different positions on the wall of the impedance tube, and Three microphone jacks 5 are installed, and the jacks are in the form of cones, and the front opening is matched with the outer diameter of the microphone to ensure sealing. This structure is convenient for the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com