A participation type long-distance client collaborative design manufacturing system including rapid prototyping units

A customer, remote technology, applied in the direction of electrical program control, calculation, comprehensive factory control, etc., can solve the problems of high cost, unhappy market response, long cycle, etc., and achieve the effect of saving mold costs, enriching life, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

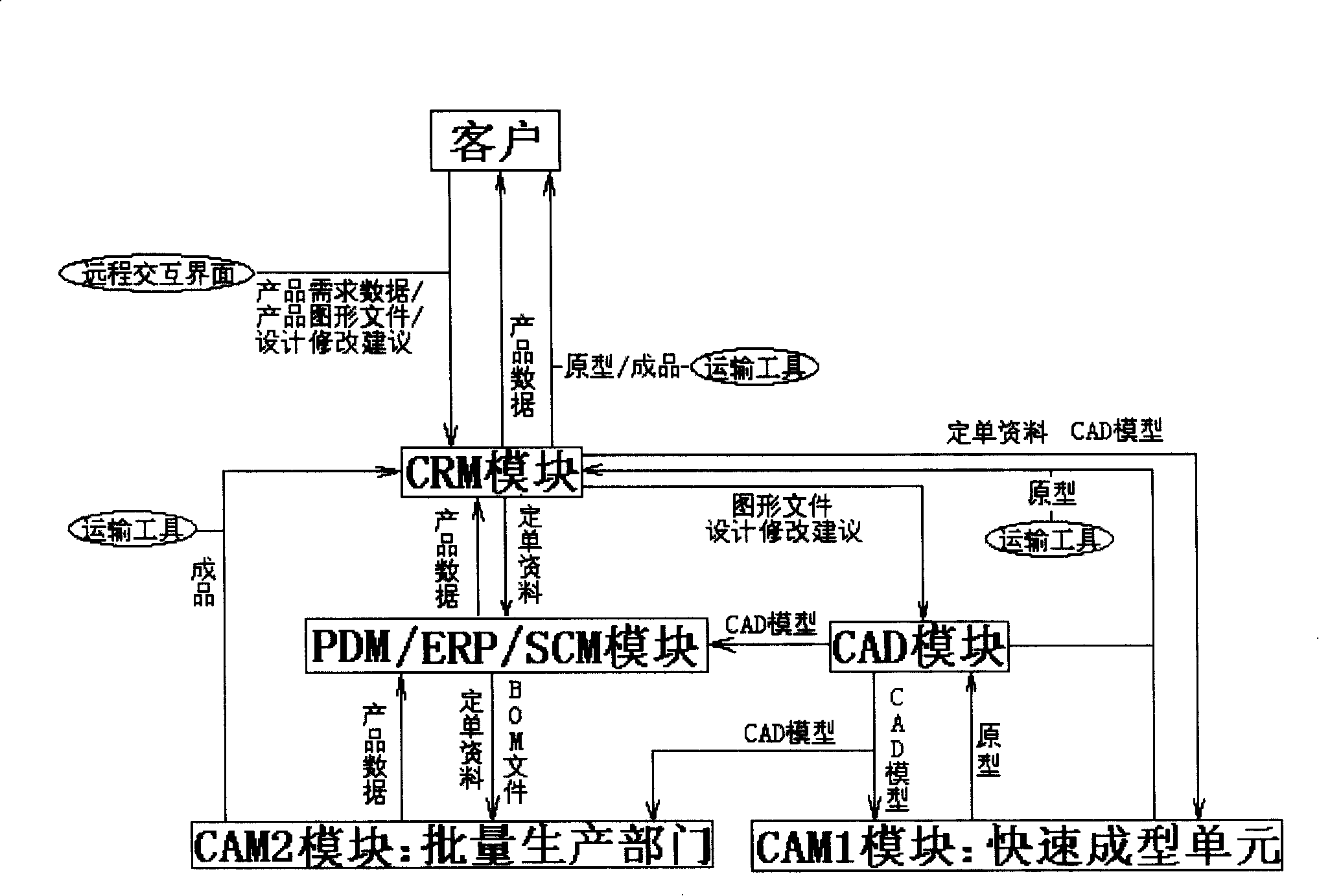

[0009] like figure 1 As shown in the figure, the remote customer inputs information expressing their individual product needs into the system through a human-computer interaction interface (such as an IE browser page, etc.). Part of this information is transmitted to the internal CRM module of the enterprise through the network to form customer relationship data and order information, and is shared with the enterprise management information system; part of the information is sent to the CAD module through the CRM module, except for the CAD from the customer that is compatible with the CAM module. In addition to model files, other graphics files or CAD model files that are not compatible with CAM modules must be processed by designers and drafters to form product CAD model files. After the CAD module is combined with the relevant modules in the ERP, data files required for production operations such as BOM (Bill of Materials) files are generated and shared throughout the system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com