An active member array structure and the corresponding manufacturing method

An array structure, active element technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as the inability to reduce process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

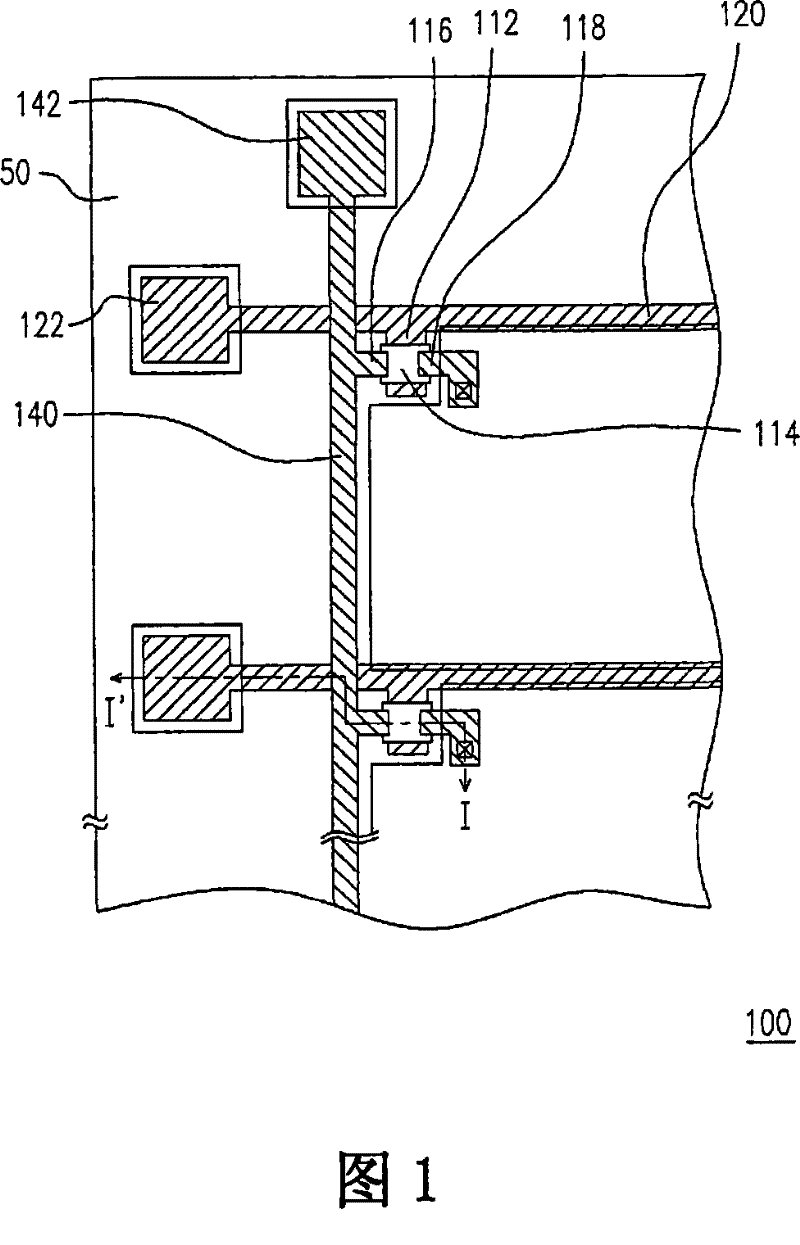

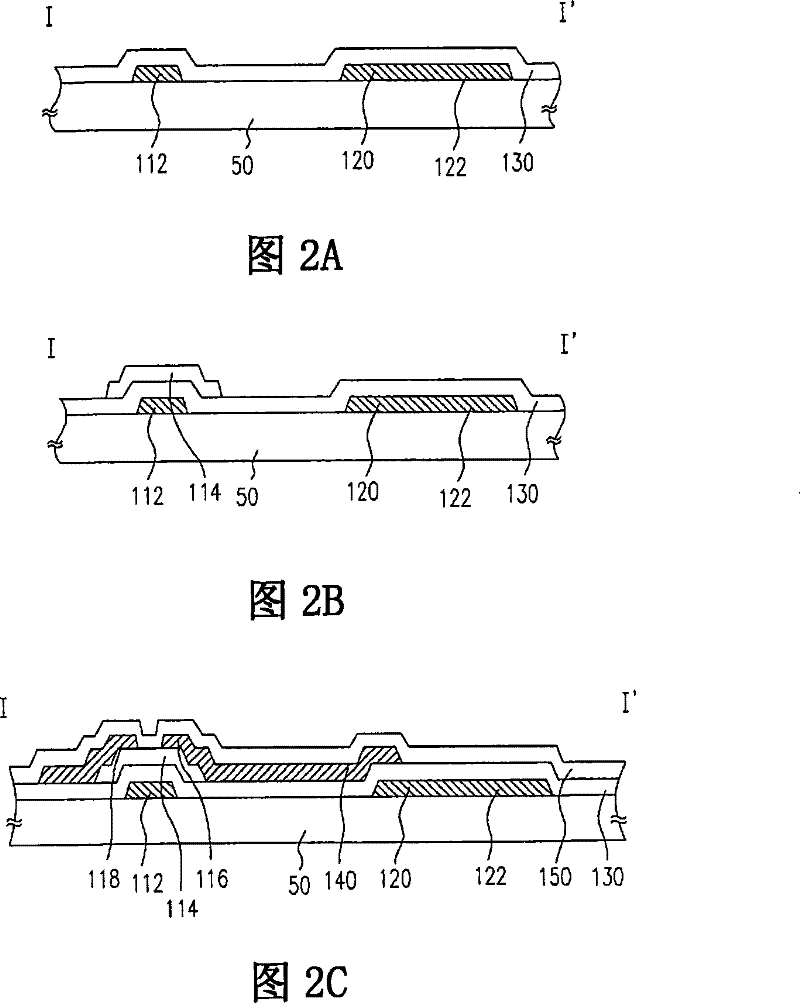

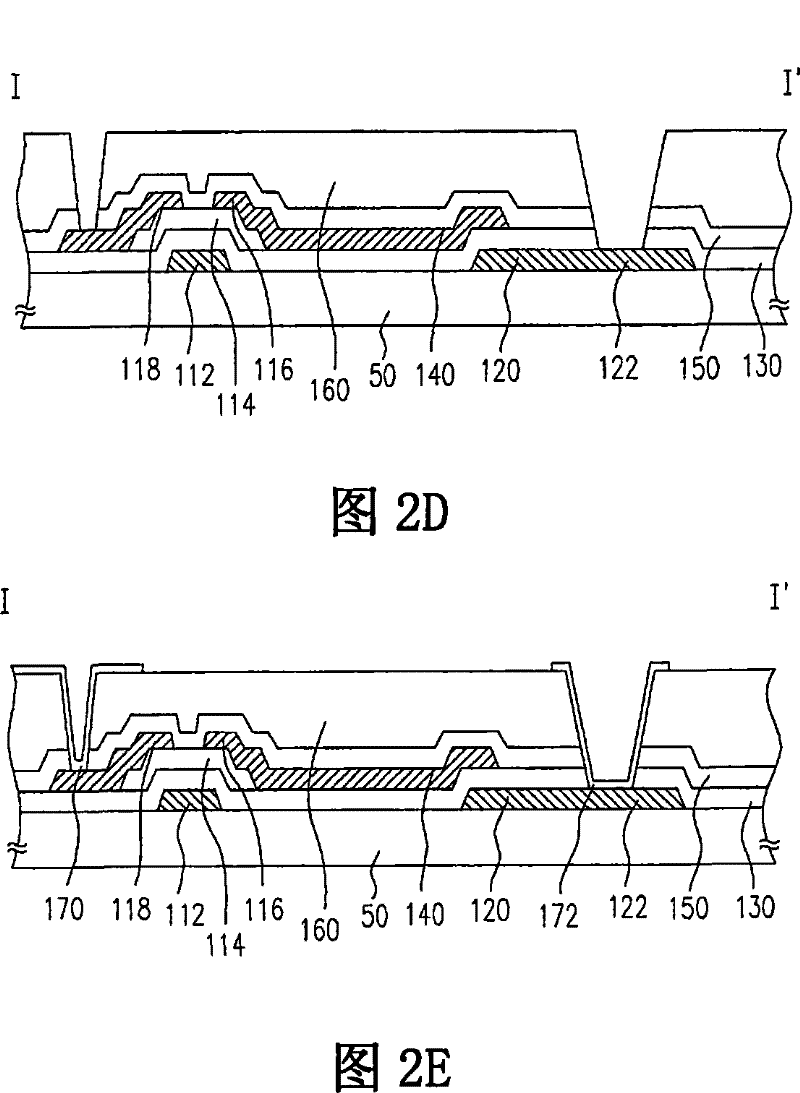

[0099] image 3 is a top view of the first mask process of the active element array structure of the first embodiment of the present invention, and Figures 4A-4D for image 3 Sectional views of the median lines AA', BB', CC' and DD'. Please refer to image 3 and Figures 4A-4D The method for manufacturing the active device array structure of this embodiment is to form a first conductor layer (not shown) on a substrate 300 first, and perform a first masking process so that the first conductor layer (not shown) ) is patterned into a first patterned conductor layer 310 . The first patterned conductor layer 310 includes a plurality of scan lines 312 , a plurality of gates 314 and a plurality of scan pads 316 , wherein the scan lines 312 are connected to the gates 314 and the scan pads 316 .

[0100] In this embodiment, the first patterned conductor layer 310 is, for example, a multi-layer metal stack structure composed of a first titanium metal layer 310A and a first aluminu...

no. 2 example

[0122] Figure 14 is the active element array structure of the second embodiment of the present invention, and Figures 15A-15D for Figure 14 Sectional view of section lines AA', BB', CC' and DD'. Please refer to Figure 14 and Figures 15A-15D The active device array structure 600 is substantially the same as the active device array structure 380 of the first embodiment, wherein the active device array structure 600 further includes a patterned protective layer 680 disposed between the patterned flat layer 360 and the substrate 300 . In addition, in this embodiment, the metal stack structure forming the gate 314, the scan line 312, and the scan pad 316 is, for example, a stack structure of aluminum metal and molybdenum metal, or a three-layer metal stack of molybdenum / aluminum / molybdenum. structure. Meanwhile, the metal structure constituting the data line 332 , the source electrode 334 , the drain electrode 336 and the data pad 338 is, for example, a laminated structur...

no. 3 example

[0127] Figure 16 shows the first mask process of the active device array structure of the third embodiment of the present invention, and Figures 17A-17D for along Figure 16 The cross-sectional view drawn by the section lines AA', BB', CC' and DD'. Please refer to Figure 16 and Figures 17A-17D , forming a first patterned conductor layer 702 on a substrate 700 . The first patterned conductor layer 702 includes a laminated structure composed of a first aluminum metal layer and a first molybdenum metal layer. The first mask process, for example, uses a normal mask to perform photolithography and etching processes to form the first patterned conductor layer 702 .

[0128] In addition, the first patterned conductor layer 702 includes scan lines 704 , scan pads 706 , gates 708 , capacitor bottom electrodes 710 and auxiliary pads 712 . The scanning line 704, the scanning pad 706, the gate 708 and the capacitor bottom electrode 710 are connected to each other, wherein the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com