A solar panel and the corresponding manufacturing method

A technology of solar panels and solar wafers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting production efficiency and product reliability, and cannot achieve high-efficiency mass production, so as to improve product performance and reliability. The effect of stability, compact structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

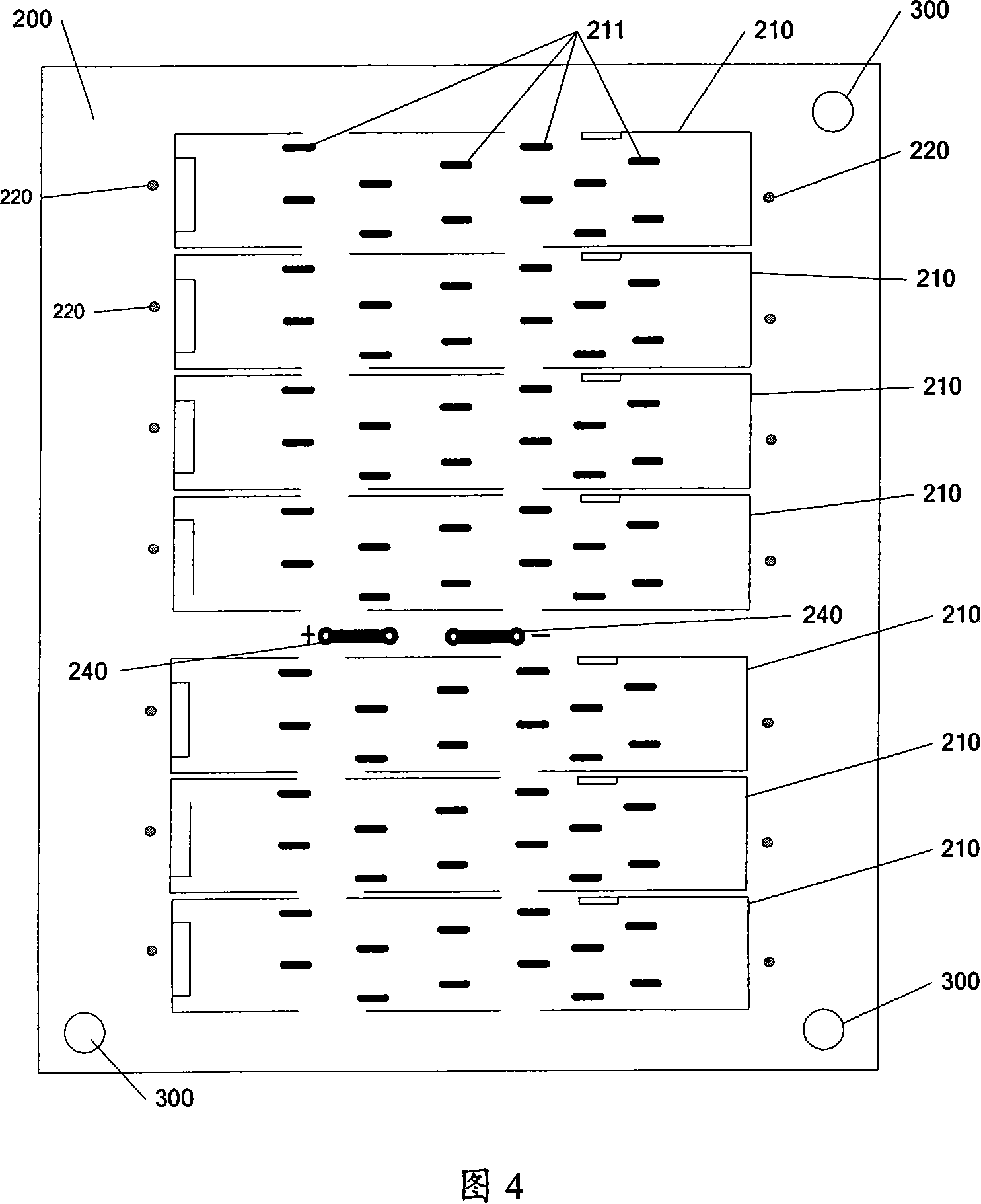

[0022] As shown in FIG. 3 and FIG. 4 , the present invention mainly provides a structural design solution of a solar battery panel. The structure of the PCB board of the solar cell panel of the present invention is as shown in Figure 3, is provided with at least one group of mounting position 210 of solar wafer on one side of PCB board 200, and it is used for automatically or manually mounting solar wafer, in each A plurality of staggered pads 211 are arranged on the group mounting position 200 for respectively connecting the positive and negative electrodes of the solar chip; two groups of electrode pads 240 are also arranged on the same surface of the PCB board 200 to connect with the solar chip. All the pads 211 connected to the positive and negative electrodes are respectively connected to two groups of electrode pads 240 through conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com