2-2 type ferroelectrics-ferrite multilayered compound magnetoelectricity material and the corresponding preparation method

A multi-layer composite and magnetoelectric material technology, applied in the manufacture/processing of electromagnetic devices, manufacture/assembly of piezoelectric/electrostrictive devices, material selection, etc., can solve problems affecting the magnetoelectric properties of materials, and achieve Improve the magnetoelectric coefficient, ensure the stress transfer, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

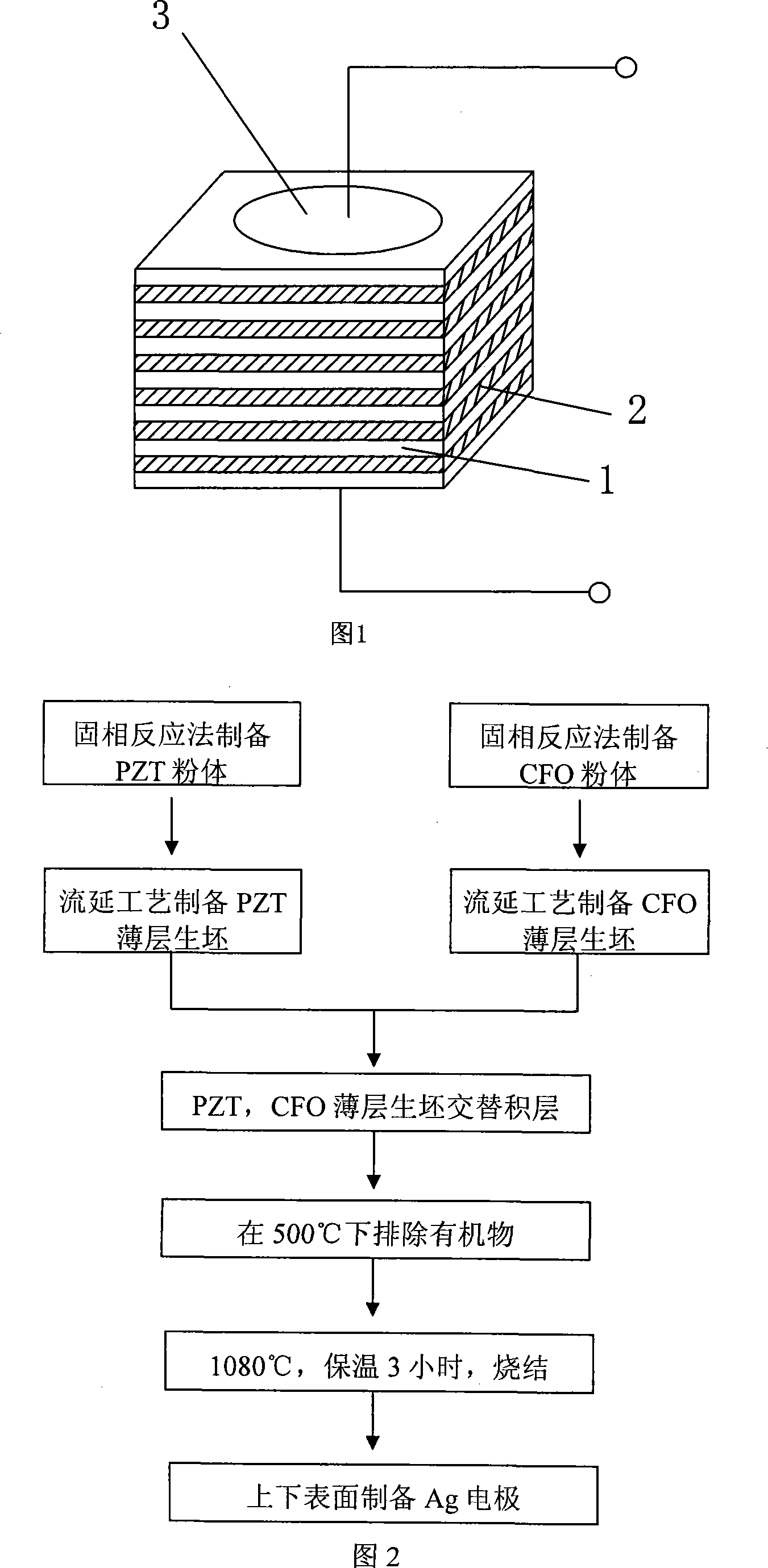

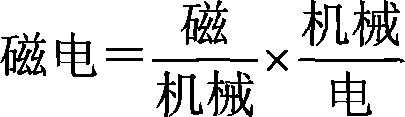

[0038] Embodiment 1, thickness ratio (t p / t c ) is a 1:1 PZT / CFO multilayer composite (see Figures 1 and 2)

[0039] (1) Preparation of PZT thin-layer green body

[0040] First prepare PZT powder. Mix the analytically pure yellow lead oxide, zirconia and titanium dioxide according to the molar ratio of 1:0.52:0.48, use absolute ethanol as the medium, carry out ball milling, and then dry; put the mixed powder after drying into the resistance furnace , calcined in the temperature range of 700-1100°C, and obtained PbZr through solid-state reaction 0.52 Ti 0.48 o 3 The powder has a particle size of 200-500nm.

[0041] A PZT thin layer green body is then prepared. Use the PZT powder prepared by the above method as raw material, add ethanol and butanone as organic solvent, add dibutyl phthalate as plasticizer, add castor oil as dispersant, and add polyvinyl butyral as binder Agents were mixed by ball milling to obtain a uniform slurry. Wherein, the add-on of ethanol is 70%...

Embodiment 2

[0050] Embodiment 2, thickness ratio (t p / t c ) is a 1:2 PZT / CFO multilayer composite

[0051] (1) Preparation of PZT thin-layer green body

[0052] First prepare PZT powder. Mix the analytically pure yellow lead oxide, zirconia and titanium dioxide according to the molar ratio of 1:0.52:0.48, use absolute ethanol as the medium, carry out ball milling, and then dry; put the mixed powder after drying into the resistance furnace , calcined in the temperature range of 700-1100°C, and obtained PbZr through solid-state reaction 0.52 Ti 0.48 o 3 The powder has a particle size of 200-500nm.

[0053] A PZT thin layer green body is then prepared. Use the PZT powder prepared by the above method as raw material, add ethanol and butanone as organic solvent, add dibutyl phthalate as plasticizer, add castor oil as dispersant, and add polyvinyl butyral as binder Agents were mixed by ball milling to obtain a uniform slurry. Wherein, the add-on of ethanol is 70% of PZT powder quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com