Novel flame generating means

A generator and flame technology, applied in combustion ignition, lighting and heating equipment, combustion methods, etc., can solve the problems of difficult design and manufacture, and achieve significant energy saving, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

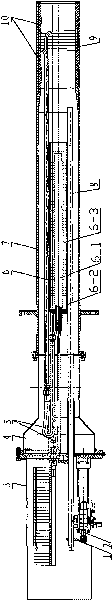

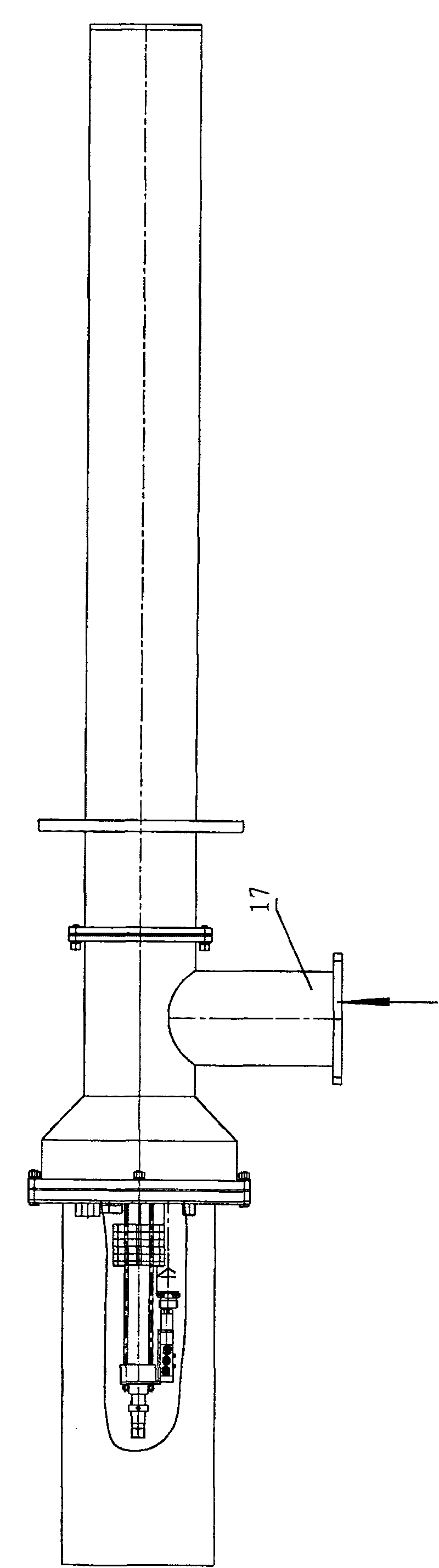

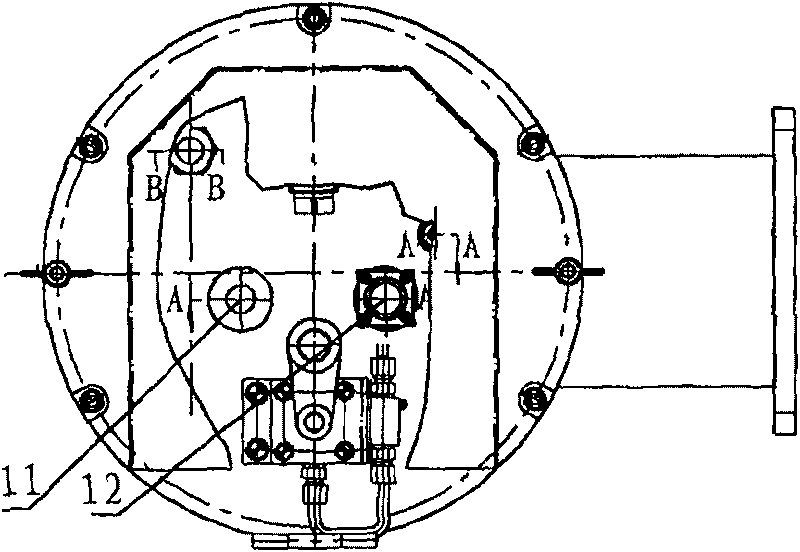

[0016] The structure of novel flame generator of the present invention is as figure 1 As shown, it is mainly composed of the following six parts: 1. Pipeline 5. Second, vaporizer 6. 3. Shell: including machine cover 3, bellows 4 and other parts. Four, air distribution device: including air distribution cylinder 7, preheating ring 9, heat insulation cover 10 and other parts. 5. Detection mechanism: including fire viewing hole 11, visible light flame detection probe 12 and other pieces. 6. Ignition mechanism: including connecting plate 1, cylinder 2, ignition gun 8 and other parts.

[0017] The second part of the above six components, that is, the unique working characteristics of the gasifier, makes the working principle of the present invention unique and novel, and the performance has better excellence. The gasifier 6 is formed by sintering the metal powder 6-3 filled with the central preheating rod 6-1 and the outer sleeve 6-2. 6-1 The outer diameter of the central preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com