Intelligent controller of gas combustion range

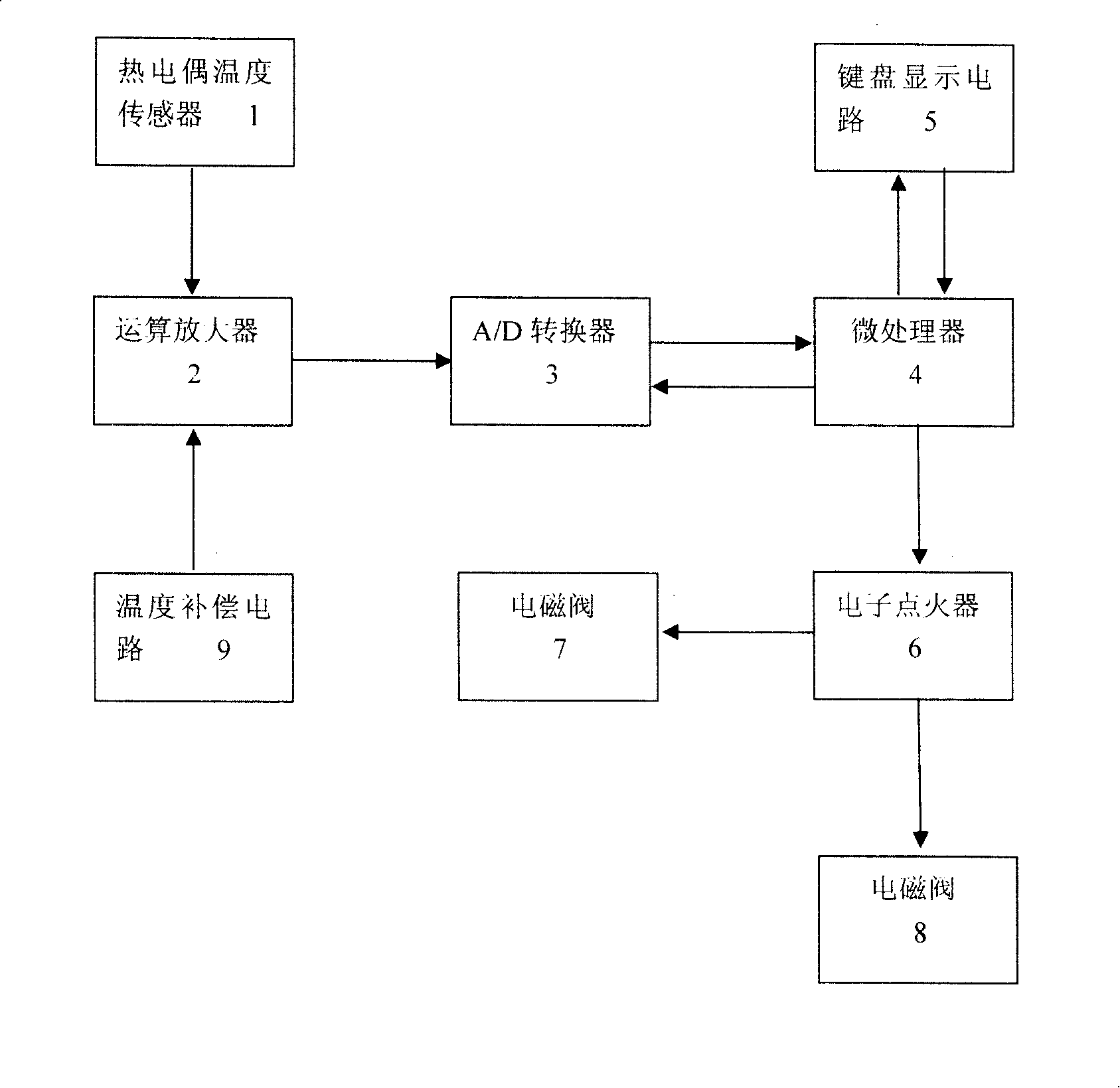

A technology of intelligent controller and gas stove, which is applied to heating fuel, household stove/stove, gaseous heating fuel, etc., can solve the problems of installation difficulty, inaccurate temperature measurement, difficult cleaning, etc., and achieves safe and reliable use and measurement accuracy. High, wide measuring range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

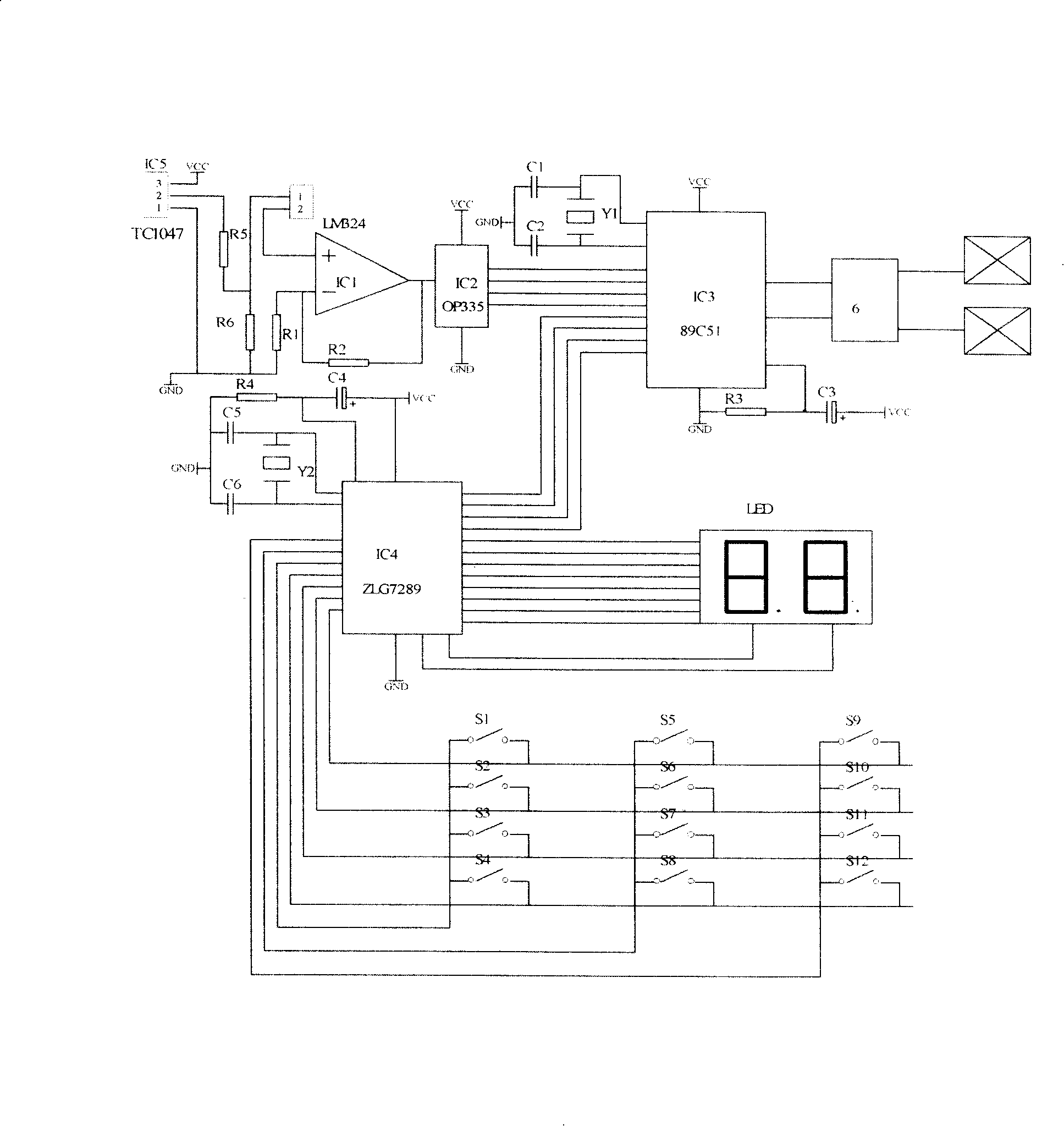

[0038] Embodiment one, cook rice with pressure cooker. Turn on the controller, connect the power supply, and initialize the system. Press button S2 pressure cooker to cook rice function key, integrated circuit IC4 checks that button S2 has been pressed, and immediately sends the key value of S2 to integrated circuit IC3 of microprocessor 4, and integrated circuit IC3 calls the rice cooking function subroutine. The integrated circuit IC3 returns a data to the integrated circuit IC4, and the integrated circuit IC4 drives the nixie tube LED according to the data sent by the integrated circuit IC3 to display the time required for cooking rice for 12 minutes. Simultaneously integrated circuit IC3 sends ignition instruction to electronic igniter (6), and electronic igniter (6) opens solenoid valve (7) and solenoid valve (8), and gas flows to burner through the pipeline of solenoid valve, and flame ignites. At the same time, the integrated circuit IC3 sends an instruction to start t...

Embodiment 2

[0039] Embodiment 2, boiling water: turn on the controller, connect the power supply, and initialize the system. Press the button S1 to boil the water function key, the integrated circuit IC4 inquires that S1 has been pressed, and immediately sends the key value of S1 to the integrated circuit IC3 of the microprocessor 4, and the integrated circuit IC3 calls the boiled water function subroutine. Simultaneously integrated circuit IC3 sends ignition instruction to electronic igniter (6), and electronic igniter (6) opens solenoid valve (7) and solenoid valve (8), and flame is ignited. At the same time, the integrated circuit IC3 sends an instruction to start the A / D converter (3). The thermocouple temperature sensor (1) sends the variation of the water temperature to the operational amplifier (2) for amplification, and then to the A / D converter (3) for analog-to-digital conversion. The microprocessor (4) reads the data change of the A / D converter (3), processes and judges the da...

Embodiment 3

[0040] Embodiment 3, steaming, boiling and stewing dishes with a pressure cooker: open the controller, connect the power supply, and initialize the system. Press button S3 pressure cooker steam, boil, stew function key, integrated circuit IC4 checks button S3 is pressed, immediately sends the key value of button S3 to integrated circuit IC3 of microprocessor 4, integrated circuit IC3 invokes pressure cooker to steam, boil, stew Function key subroutine. The integrated circuit IC3 returns a data to the integrated circuit IC4 of the keyboard display circuit 5, and the integrated circuit IC4 drives the nixie tube LED according to the data sent by the integrated circuit IC3 to display the default required time of 10 minutes. The required time can also be set through S11 and S12. Simultaneously integrated circuit IC3 sends ignition instruction to electronic igniter (6), and electronic igniter (6) opens solenoid valve (7) and solenoid valve (8), and flame is ignited. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com