Light-redirecting film containing optical modification layer

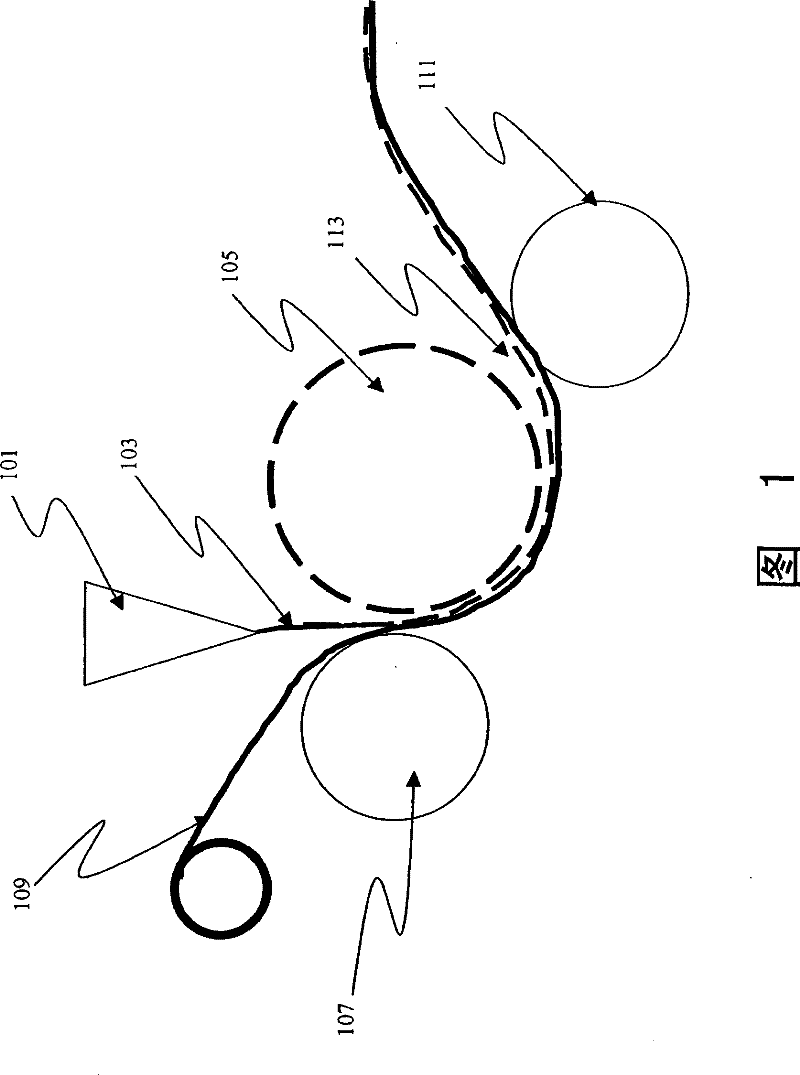

一种光重新定向、光学调整层的技术,应用在光学、光学元件、非线性光学等方向,能够解决光重新定向薄膜有限等问题,达到高亮度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

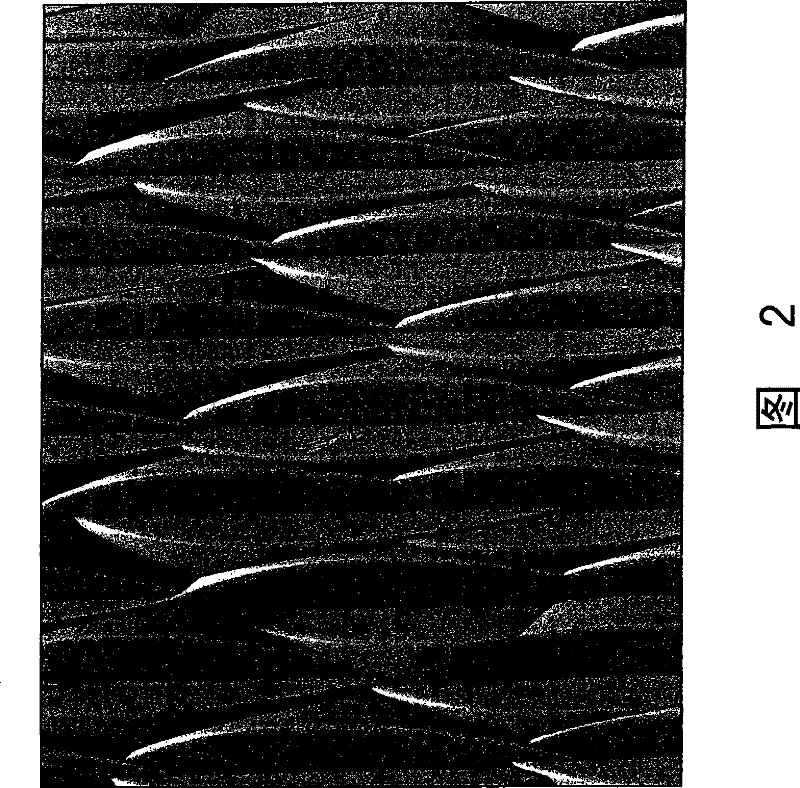

[0114] In this example, several optically modifying layers were used to coat a polycarbonate substrate containing individual integrated optical elements measuring 1200 microns long by 35 microns wide by a height of is 27 microns, and the apex angle is about 90 degrees. A 13 inch wide microreplicated polycarbonate support (manufactured by Eastman Kodark, Rochester, NY) was coated to produce an enhanced wide angle appearance with a more slowly varying critical angle than the optic without the optical correction layer.

[0115] To prepare 1 kg of dispersion to be coated onto a microreplicated polycarbonate support, 988.3 g of water and 11.7 g of photographic gelatin, along with a small amount of surfactant (to aid in the microsphere coating process) were added to the Together. The entire dispersion was heated to 50°C.

[0116] The gelatin and matte microsphere dispersions were liquefied at 50 degrees Celsius (°C), coated onto microreplicated polycarbonate supports at a wet coat...

Embodiment 2—23

[0118] A 13 inch wide microreplicated polycarbonate support (manufactured by Eastman Kodark, Rochester, NY) was coated to create an enhanced wide-angle appearance.

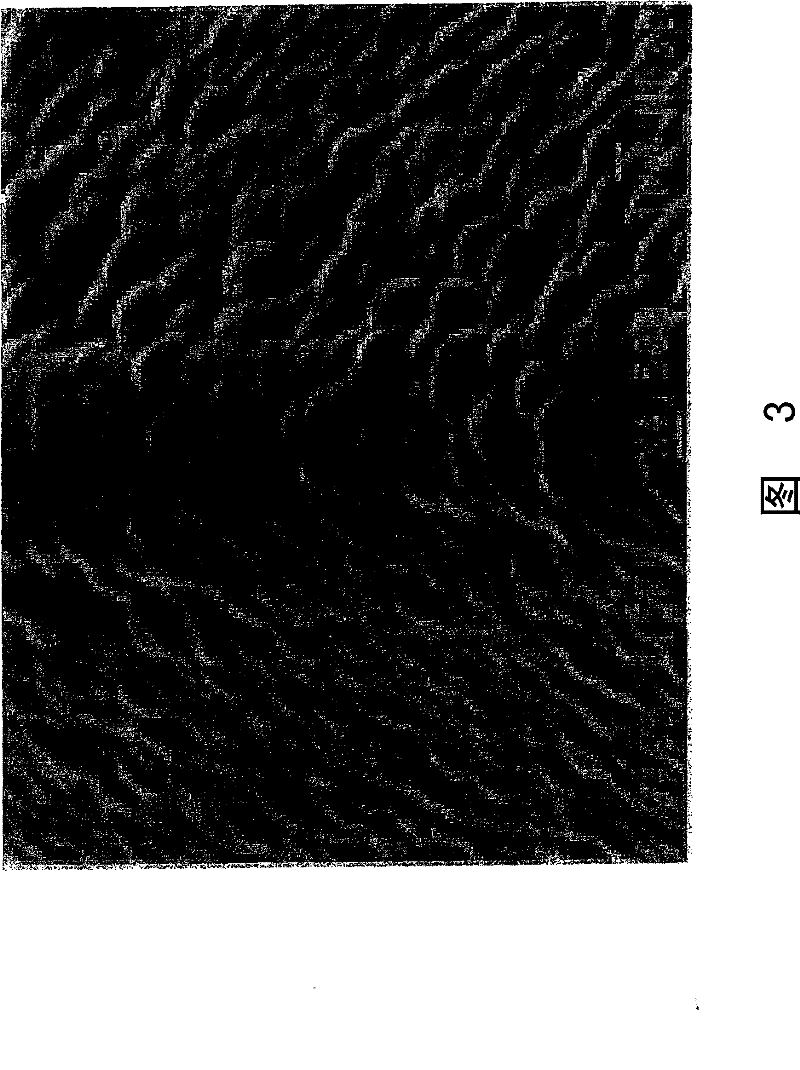

[0119] A 1 kg dispersion of the gelatin and matte microsphere composition was prepared as follows. Starting with 702 grams of distilled water, an aqueous solution of homopolymer and gelatin was formed from 60 grams of photographic gelatin and 234 grams of methyl 2-methyl-2-acrylate (PMMA) (Example 2). Microscopic analysis indicated that the dispersion consisted of uniform 1.3 micron matte microspheres and an aqueous gelatin medium. As shown in Table 1, as the size of the matt microspheres increases or decreases, minor changes to the formulation are required. In addition, as the material composition of the matte microspheres changes as shown in Table 1, the formulation needs to be fine-tuned.

[0120] To prepare 1 kg of a dispersion to be coated onto a microreplicated polycarbonate support, 962 g of water and 11....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com