Display panel

A display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems affecting image quality, long exposure time, liquid crystal layer contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

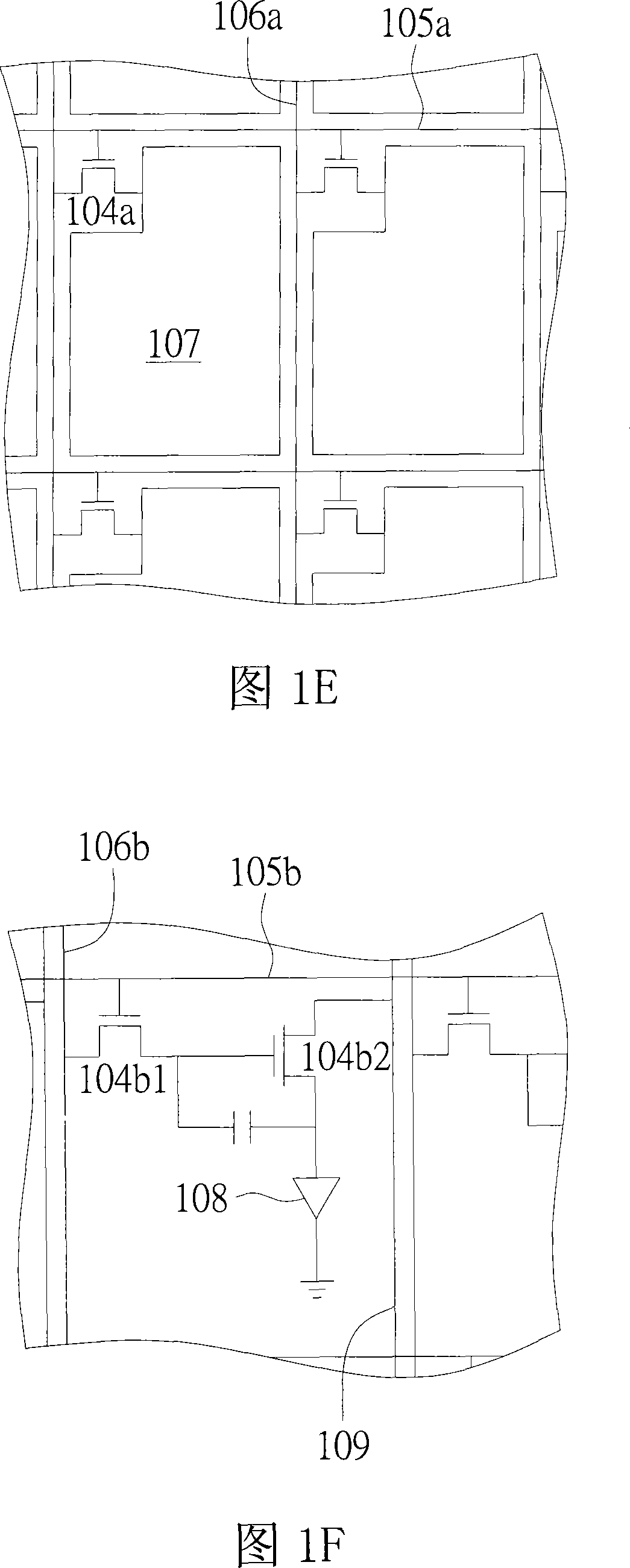

[0053] FIG. 2 is a cross-sectional view of a display panel according to a first embodiment of the present invention. As shown in FIG. 2 , the display panel 20 includes a color filter substrate 210 , an active array substrate 200 and a liquid crystal layer 230 therebetween. The display panel 20 has a display area T and a bonding area C, and the display area T is surrounded by the bonding area C along its periphery.

[0054] The color filter substrate 210 includes a base 211, and the light-shielding layers 212a and 212b are located on the base 211. In the display area T, the color filter layers R, G, and B are located on the base 211, which can partially cover the light-shielding layer 212a, and are insulated. The layer 223 covers the light-shielding layer 212a and the color filter layers R, G, and B. The material of the insulating layer 223 is, for example, an organic material. The common electrode 224 is located on the insulating layer 223. The reflective structure 225 include...

no. 2 example

[0059] FIG. 3 is a cross-sectional view of a display panel according to a second embodiment of the present invention. As shown in FIG. 3 , the difference from the first embodiment is that the reflective structure 325 is located on the active array substrate 300 , and the rest of the components are substantially the same, and will not be repeated here. When the process of curing the photosensitive sealant 320 is performed, the light L is provided from the side of the color filter substrate 310 into the photosensitive sealant 320, and then reflected by the reflective structure 325 to form the light L', which enters the light again. The sensitive sealing glue 320 is used to cure the photosensitive sealing glue 320 .

no. 3 example

[0061] FIG. 4 is a cross-sectional view of a display panel according to a third embodiment of the present invention. As shown in FIG. 4 , the liquid crystal panel 40 includes a color filter on an active array substrate (color filter on array, COA) 400 , an opposite substrate 410 and a liquid crystal layer 430 therebetween. The difference from the first embodiment is that the liquid crystal panel 40 uses color filters on the active array upper substrate 400 , so the opposite substrate 410 does not need a color filter layer. In the color filter active array upper substrate 400 , the light-shielding layer 412 b and the color light layers R, G, and B are located on the insulating layer 403 . The manufacturing process of the reflective structure 425 can directly form the first adjustment structure 425 a , the second adjustment structure 425 b and the reflective layer 425 c on the substrate 411 , or form the metal reflective structure on the substrate 411 . The rest of the compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com